Device and method of connection of carrier roller bearing seat and roller sheet

A technology for connecting equipment and bearing housings, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of high processing energy consumption, low work efficiency, and easy deformation and cracking of idler bearing housings and roller skins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

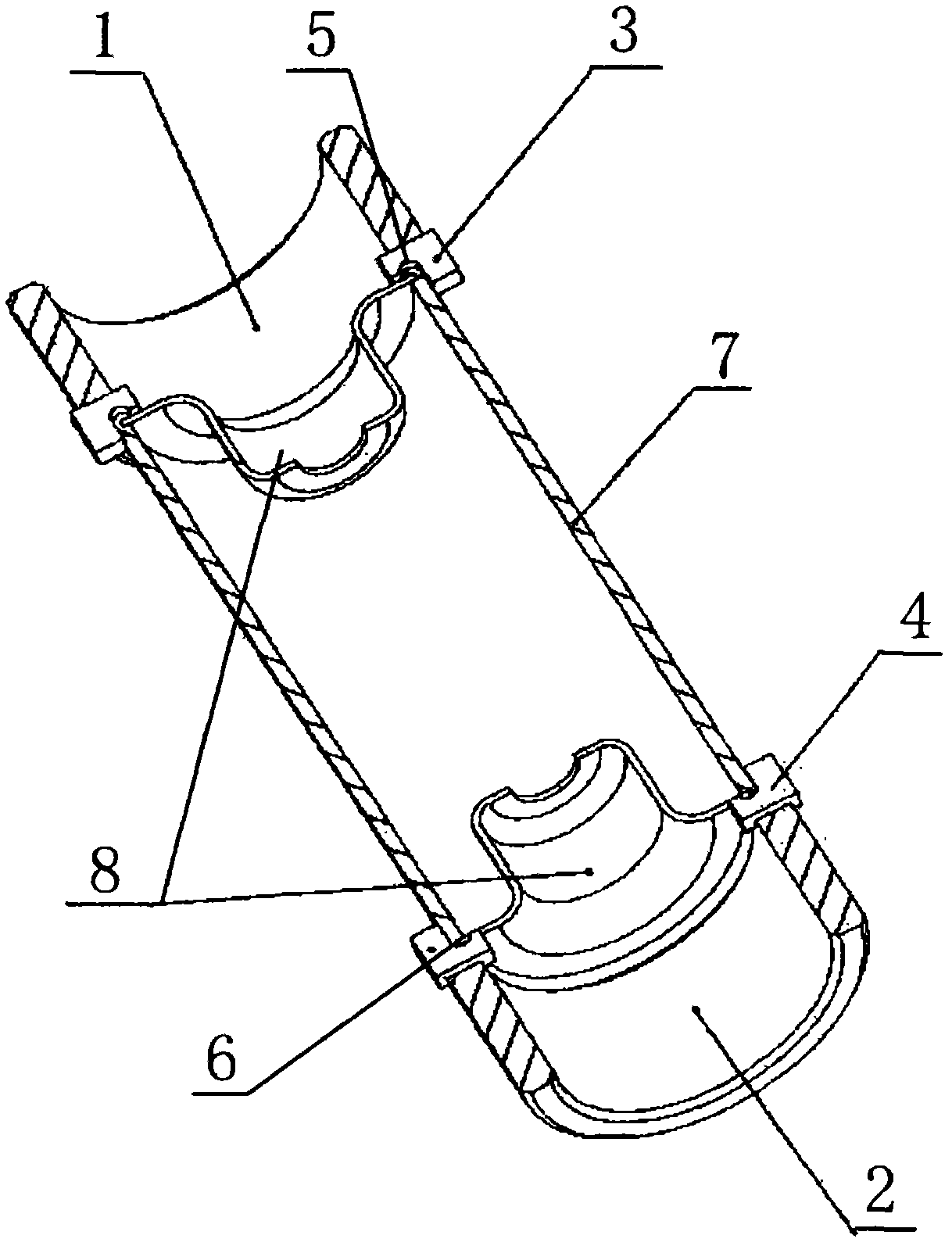

[0010] A connection device between a roller bearing housing and a roll skin, comprising a left forming extrusion tube 1, a right forming extrusion tube 2, several left forming extrusion blocks 3, and several right forming extrusion blocks 4; Extrusion blocks 3 are evenly distributed around the axis of the left forming extruded tube 1 and fixed on one end surface of the left forming extruded tube 1; each right forming extruded block 4 is evenly distributed and fixed on the right One side end surface of the forming extrusion tube 2; left extrusion groove 5 is opened on the outer end surface of each left forming extrusion block 3; right extrusion groove 6 is opened on the outer end surface of each right forming extrusion block 4 ;

[0011] A method for connecting an idler chock and a roll skin, said method being completed in a device for connecting an idler chock and a roll skin as described in claim 1, the method is realized by the following steps: 1 ) Fix the idler roller skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com