Preparation method three-dimensional multistage SnO2 nanoflowers

A nanoflower, three-dimensional technology, applied in nanotechnology, tin oxide and other directions, can solve the problems of cumbersome preparation methods, environmental pollution, and impact on human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Weigh 0.45gSnCl 2 2H 2 O was dissolved in 20mL distilled water, stirred for 20min to obtain solution ①;

[0021] 2) Weigh 0.32g NaOH and 0.72g CTAB and dissolve in 20mL distilled water, stir for 20min to obtain solution ②;

[0022] 3) Mix the solution ① with the solution ②, and stir for 40 minutes to obtain a uniform solution ③;

[0023] 4) Transfer the solution ③ into a 50mL reaction kettle, and heat at 130°C for 24h;

[0024] 5) The product was centrifuged, washed with water and ethanol five times, dried at 60°C for 13 hours to obtain a yellow-brown product; roasted in a muffle furnace at 400°C for 4 hours to collect the yellow-brown product.

Embodiment 2

[0026] 1) Weigh 0.46gSnCl 2 2H 2 O was dissolved in 20mL distilled water and stirred for 20min to obtain a solution ④;

[0027] 2) Weigh 0.42g NaOH and 0.73g CTAB and dissolve in 20mL distilled water, stir for 20min to obtain the solution ⑤;

[0028] 3) Mix the solution ④ with the solution ⑤, and stir for 40 minutes to obtain a uniform solution ⑥;

[0029] 4) Transfer the solution ⑥ to a 50mL reaction kettle, and heat it with water at 130°C for 24h;

[0030] 5) The product was centrifuged, washed with water and ethanol five times, dried at 60°C for 13 hours to obtain a yellow-brown product; roasted in a muffle furnace at 400°C for 4 hours to collect the yellow-brown product.

Embodiment 3

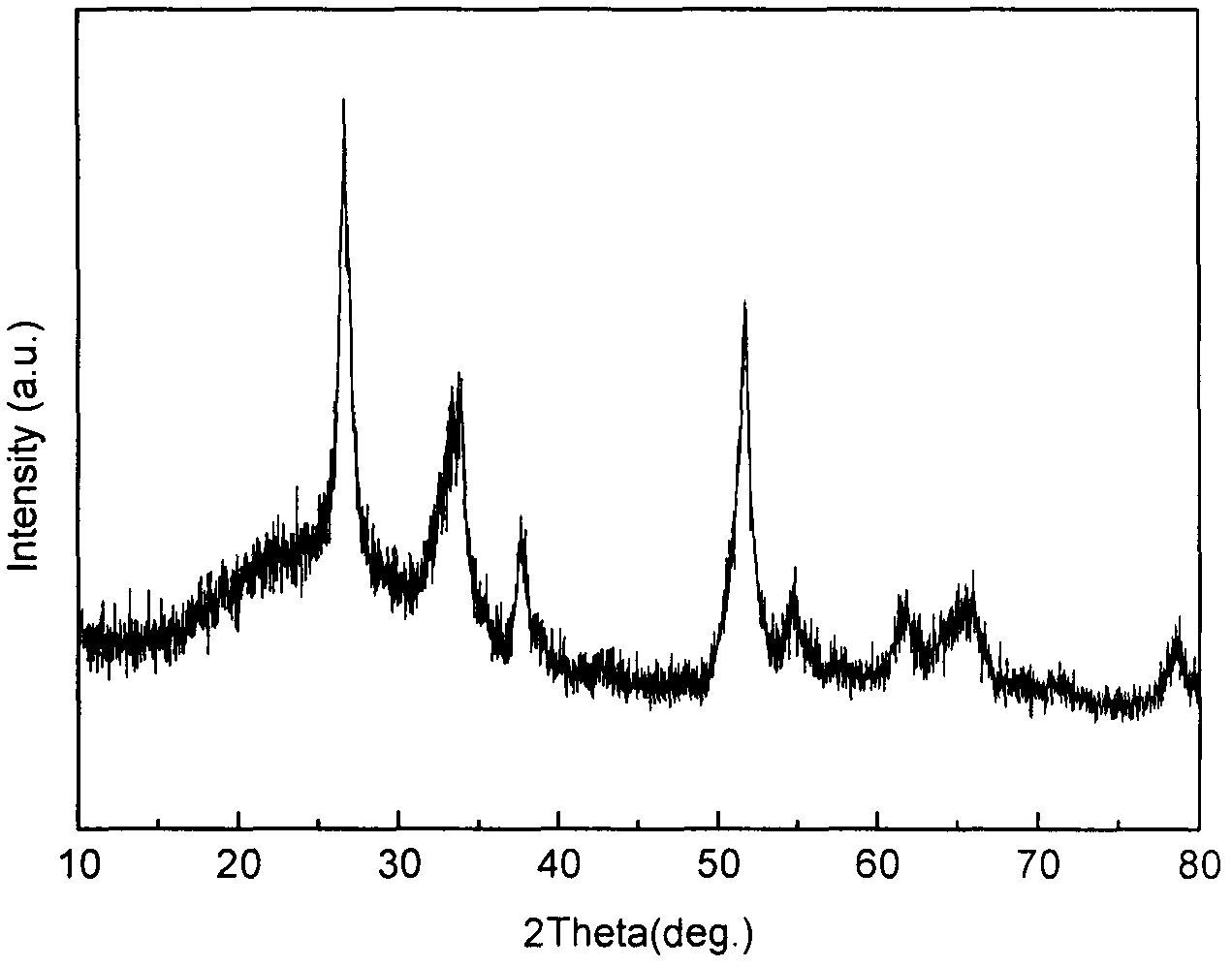

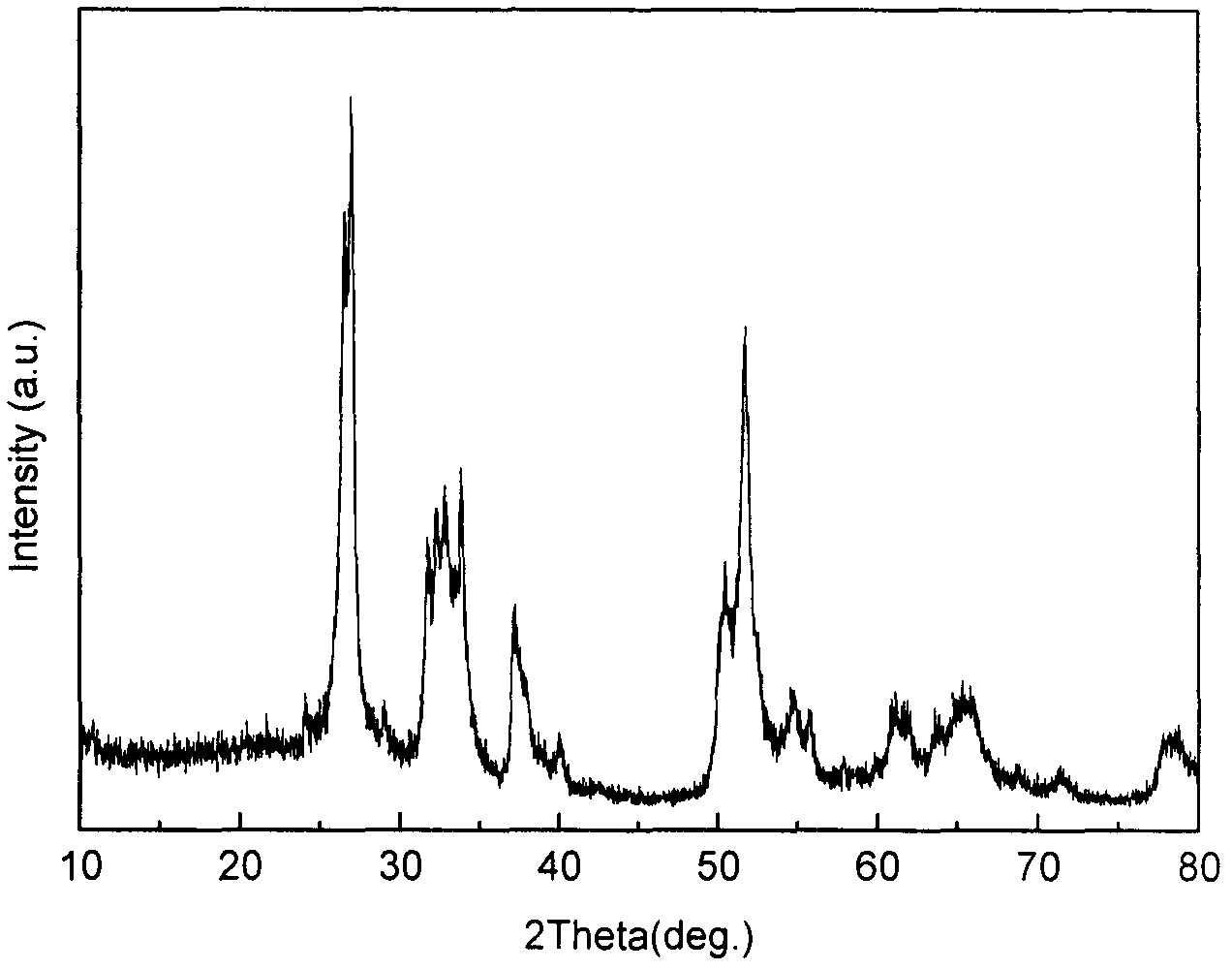

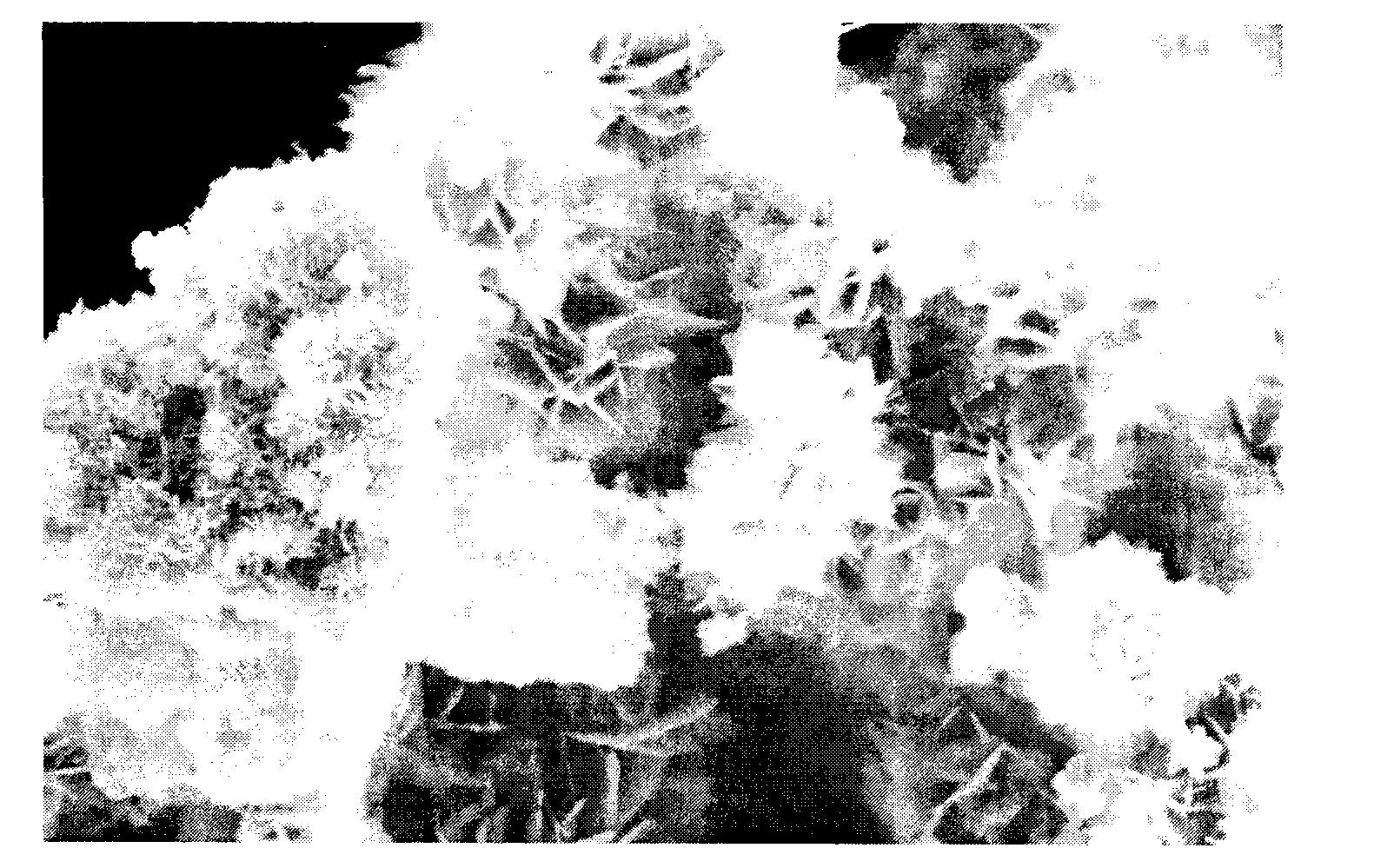

[0032] For the three-dimensional multi-level SnO prepared in Examples 1 and 2 2 X-ray diffraction experiment (XRD) of nanoflower material: the phase analysis of the sample is carried out on the D / max-2500 X-ray diffractometer produced by Rigaku Corporation, the measurement conditions: graphite monochromatic detector, tube flow 100mA, CuKα radiation source , with a step width of 0.02°. Compared with the JCPDF standard spectrum (41-1445), the spectral lines of the sample are indexed, indicating that the products are all a single tetragonal SnO 2 The crystal system and XRD spectrum are as follows figure 1 , figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com