Stirring device used for plate glass melting kiln neck

A technology of stirring device and flat glass, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of heat loss and the inability of thermal repair of stirring device, and achieves simple structure, good thermal insulation effect and good stirring effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

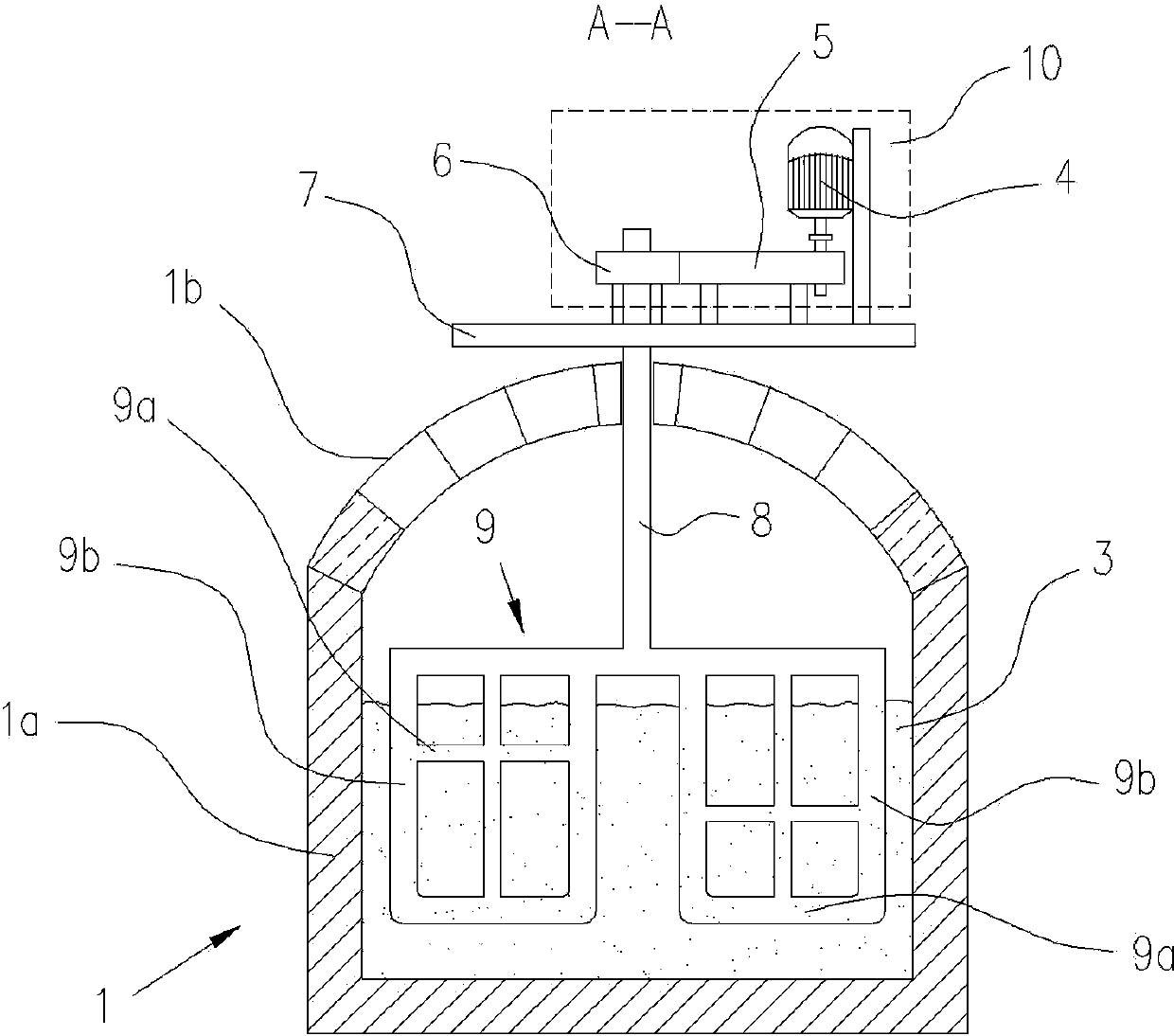

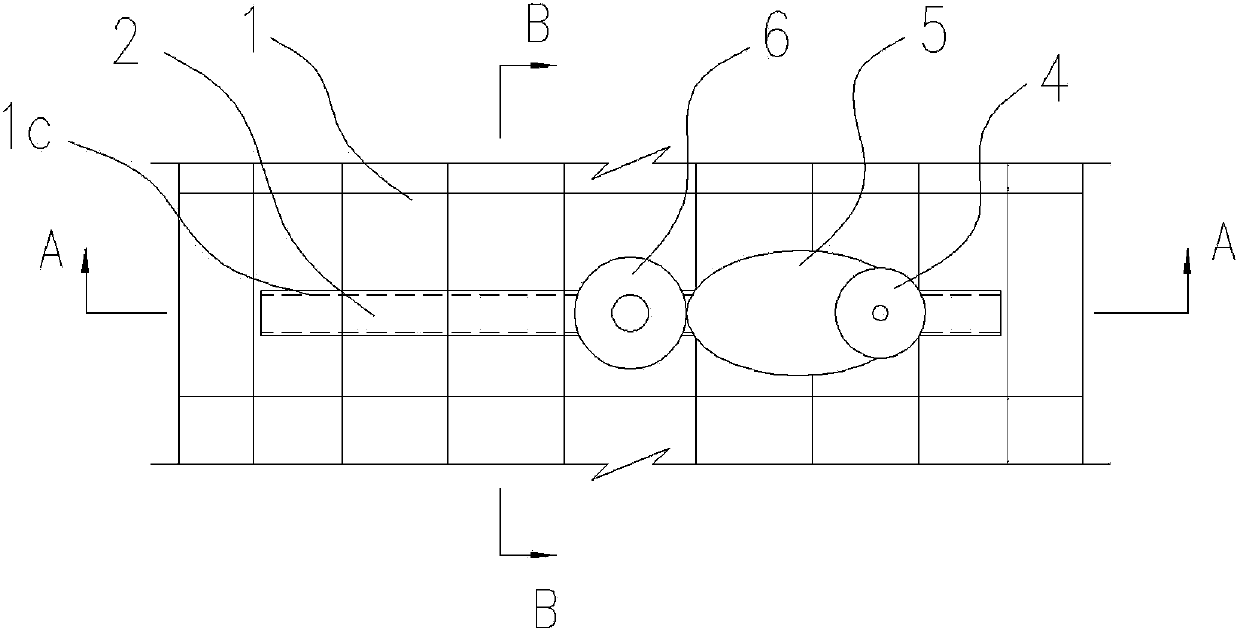

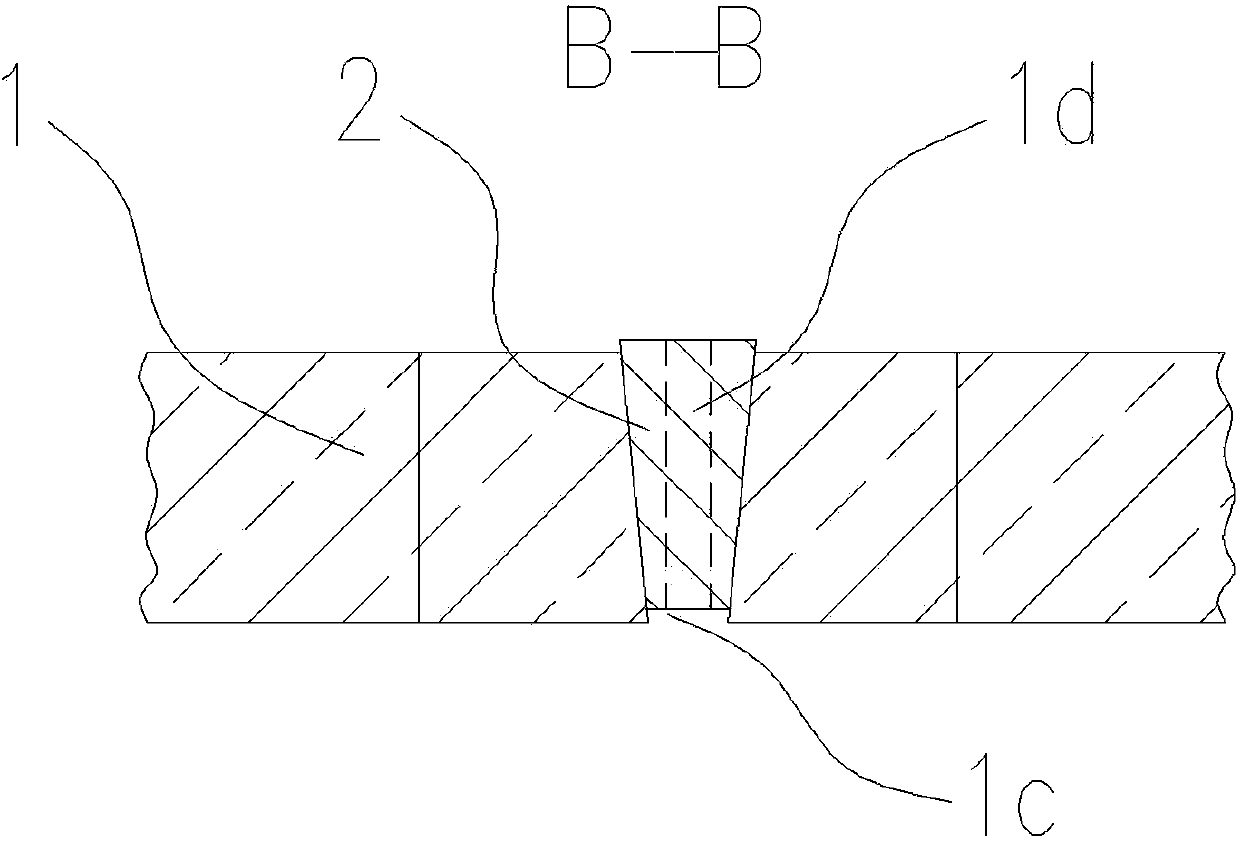

[0017] Such as figure 1 and figure 2 As shown, the present invention provides a stirring device for the neck of a flat glass melting furnace, which includes a neck 1, and the neck 1 is composed of a side wall 1a and a dome 1b. A crossbeam 7 is arranged above the vault 1b, and a power transmission mechanism 10 is connected on the crossbeam 7. The power transmission mechanism 10 includes a motor 4, a speed reducer 5 and a drive gear 6. The motor 4 is connected to the speed reducer 5, and the speed reducer 5 Connect the driving gear 6, characterized in that: the driving gear 6 is connected to one end of the stirring shaft 8, and the other end of the stirring shaft 8 is connected to the stirring mechanism 9, the stirring mechanism 9 is a flat structure, and cooperates with the opening 1c, and the stirring mechanism 9 passes through the opening 1c extends into the glass liquid 3.

[0018] The stirring mechanism 9 is a mesh stirring tooth connected to one end of the stirring shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com