Synthesis method of sec-butylbenzene

A technique for the synthesis of sec-butylbenzene, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., and can solve the problems of unstable synthesis catalyst activity and low selectivity of sec-butylbenzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

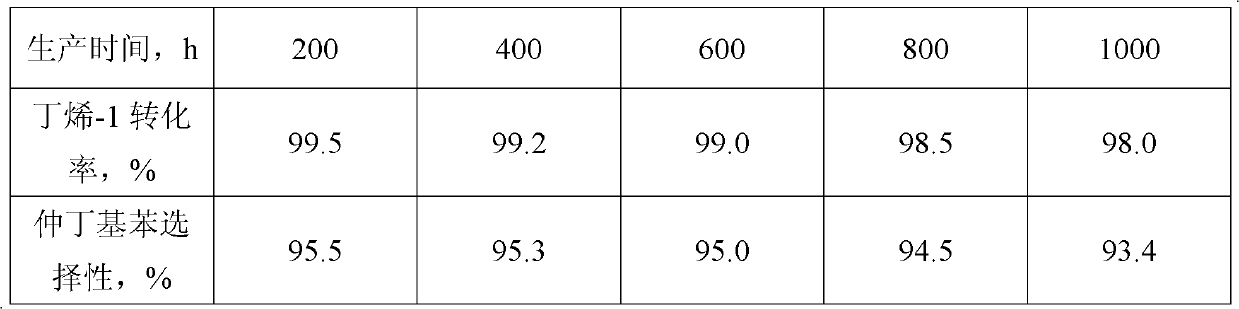

[0019] Embodiment 1: the sec-butylbenzene synthesis when using butene-1 as C4 raw material

[0020] 20g of cylindrical (diameter 1mm) containing at least aluminum-rich β molecular sieve catalyst (60% (mass fraction) molecular sieve / 40% (mass fraction) binder, etc.) In the tubular reactor with a single bed, the gaps at both ends of the catalyst in the reactor are filled with quartz sand. After filling the reactor system with benzene, gradually increase the temperature and pressure. When the reaction temperature reaches 145°C and the reaction pressure reaches 2.0MPa, butene-1 (with isobutene content less than 0.5%) is cut into the reactor, and the weight hourly space velocity is controlled for 3h -1 and benzene molar ratio is 3 under the condition of sec-butylbenzene synthetic reaction, along with the change of butene-1 conversion rate, change reaction conditions appropriately, for example, can increase reaction temperature etc. when the conversion rate of carbon four olefins ob...

Embodiment 2

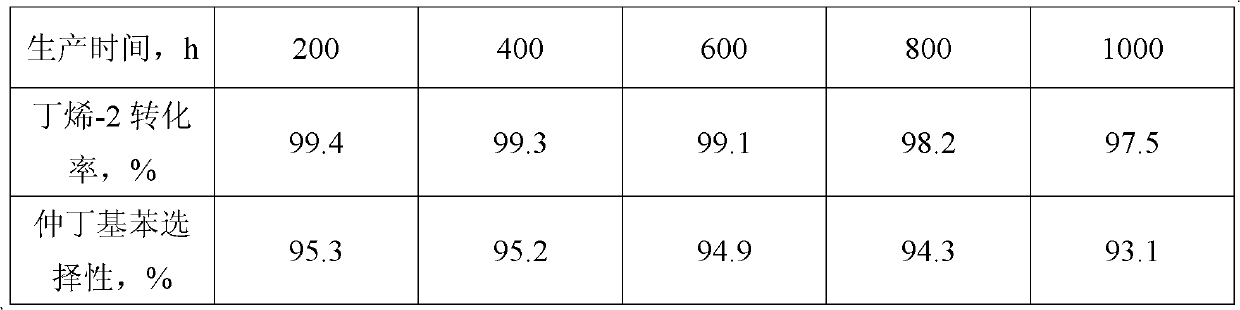

[0023] Embodiment 2: Use mixed n-trans-butene-2 to synthesize sec-butylbenzene when it is a carbon four raw material

[0024] 20g of cylindrical (diameter 1mm) containing at least aluminum-rich β molecular sieve catalyst (60% (mass fraction) molecular sieve / 40% (mass fraction) binder, etc.) In the tubular reactor with a single bed, the gaps at both ends of the catalyst in the reactor are filled with quartz sand. After filling the reactor system with benzene, gradually increase the temperature and pressure. When the reaction temperature reaches 148°C and the reaction pressure reaches 2.0 MPa, butene-2 (isobutene content is less than 0.5%, butene-255.2%, trans-butene-2 44.6 %,) cut into the reactor, control the weight hourly space velocity 8h -1 And the molar ratio of benzene is 15, along with the variation of mixed butene-2 conversion ratio, change reaction conditions appropriately, for example, can increase reaction temperature etc. when carbon tetraolefin conversion ...

Embodiment 3

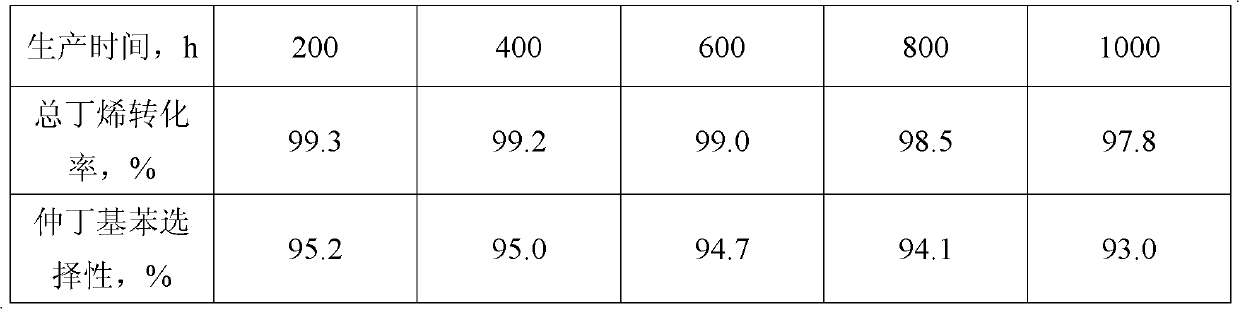

[0027] Example 3: Synthesis of sec-butylbenzene when using mixed butene-1 and n-trans-butene-2 as carbon four raw materials

[0028]50g of cylindrical (diameter 1mm) containing at least aluminum-rich β molecular sieve catalyst (60% (mass fraction) molecular sieve / 40% (mass fraction) binder, etc.) In the tubular reactor with a single bed, the gaps at both ends of the catalyst in the reactor are filled with quartz sand. After the benzene is filled with the reactor system, gradually raise the temperature and boost the pressure. When the reaction temperature reaches 147° C. and the reaction pressure reaches 2.0 MPa, the mixed butene (isobutene content is less than 0.5%, butene-150.2%, butene-2 25.2%, Trans-butene-2 24.2%,) cut into the reactor, control the weight hourly space velocity 5h -1 And the molar ratio of benzene is 8, along with the change of mixed butene-1 and butene-2 total conversion rate, change reaction conditions appropriately, for example, can improve reac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap