Prefabricate type nautical fixed platform and installing method

A technology of fixed platform and installation method, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of difficult transportation of building materials, damage to the marine environment, large climate impact, etc., and achieve convenient and rapid installation and firm main structure. , the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

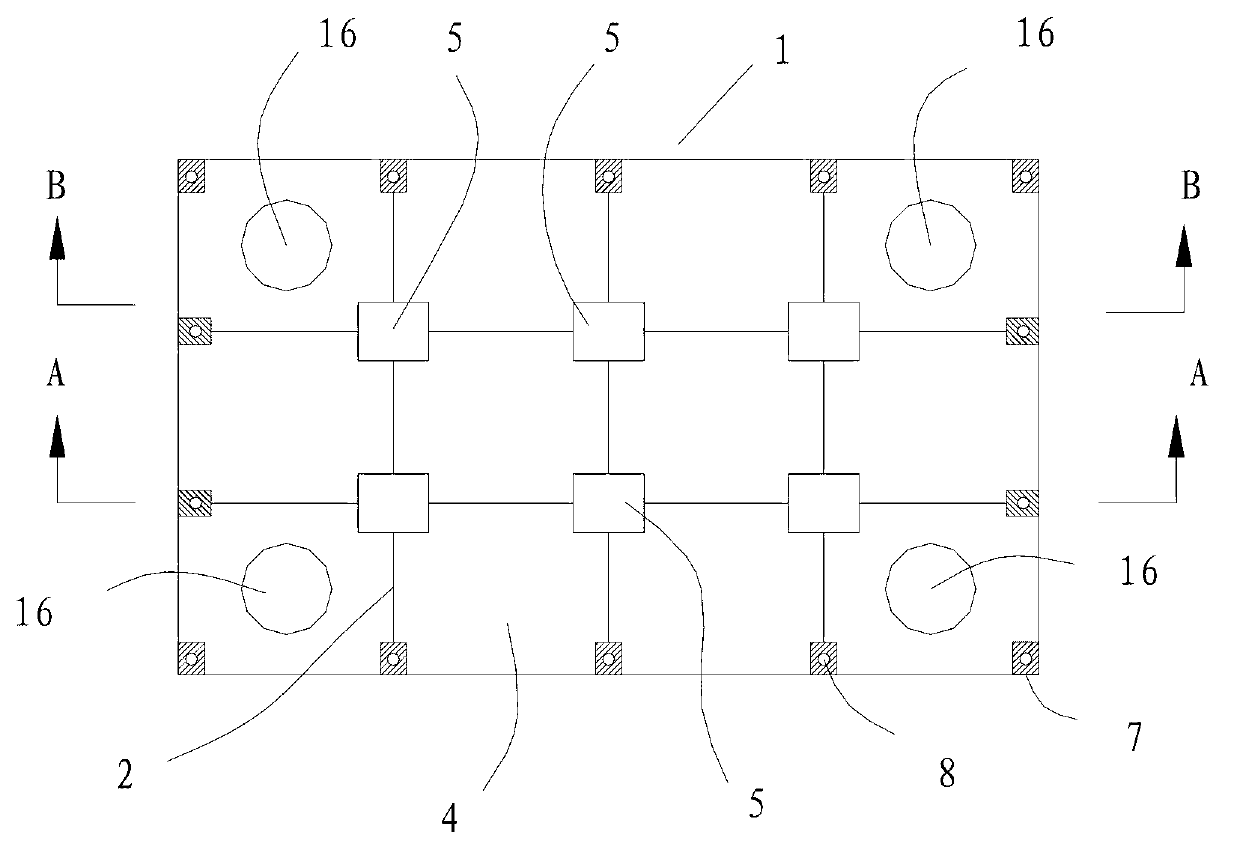

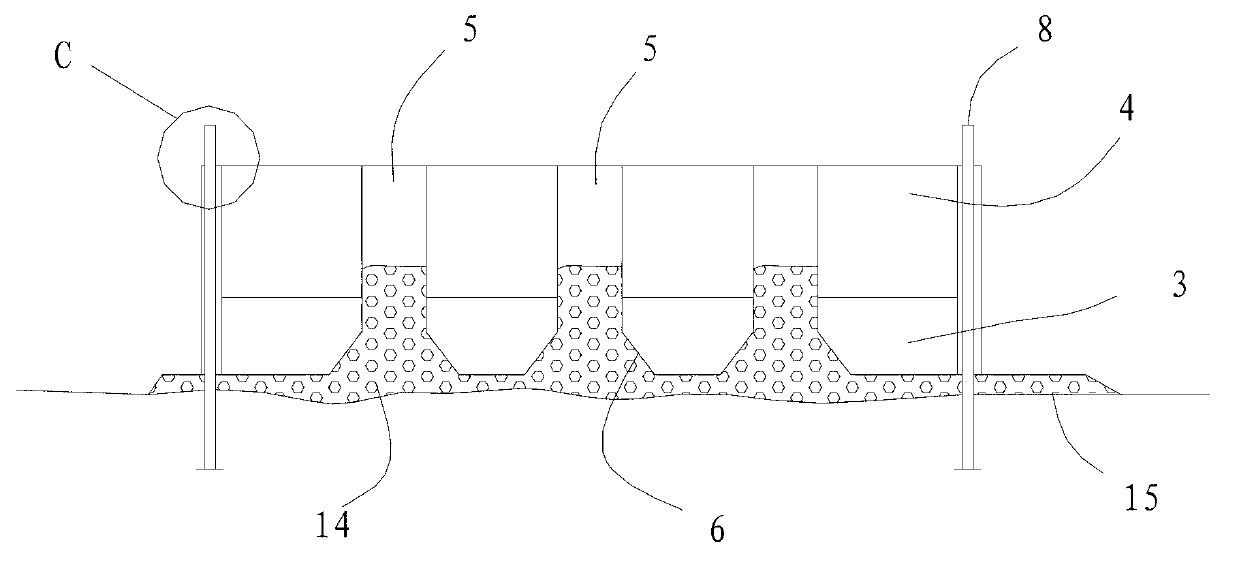

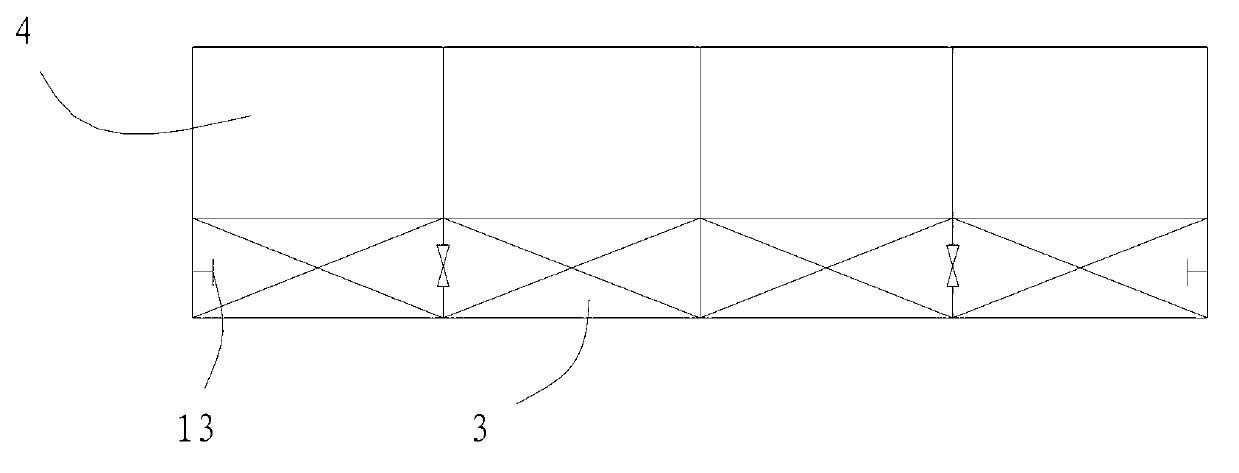

[0025] refer to Figure 1-4 , is a prefabricated fixed offshore platform, including a prefabricated platform main body 1, in which several watertight compartments 4, ballast tanks 3, gravel tanks 5 and reserved holes 16 are arranged separated by bulkheads 2, wherein The ballast tank 3 is located at the bottom of the main body 1, the watertight tank 4 is located above the ballast tank 3, the bottom of the gravel tank 5 is provided with a trumpet-shaped gravel passage 6 communicating with the outside of the main body 1, and several Each positioning device includes a positioning pile 8 that can extend out of the bottom of the main body 1 and an adjustment device that can adjust the length of the positioning pile 8 extending out of the bottom of the main body 1. The adjustment device includes a pile hole 7 arranged on the main body 1. , pulley 11, steel cable 12 and the fixed column 9 and the clamp 10 that are arranged on the platforms on both sides of the pile hole 7 top, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com