Outdoor operation ladder

A technology for outdoor work and forestry, applied to ladders, buildings, building structures, etc., can solve the problems of inconvenience, high production cost, unfavorable outdoor use, etc., and achieve the effect of being easy to carry, reducing work efficiency, and stabilizing the supporting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

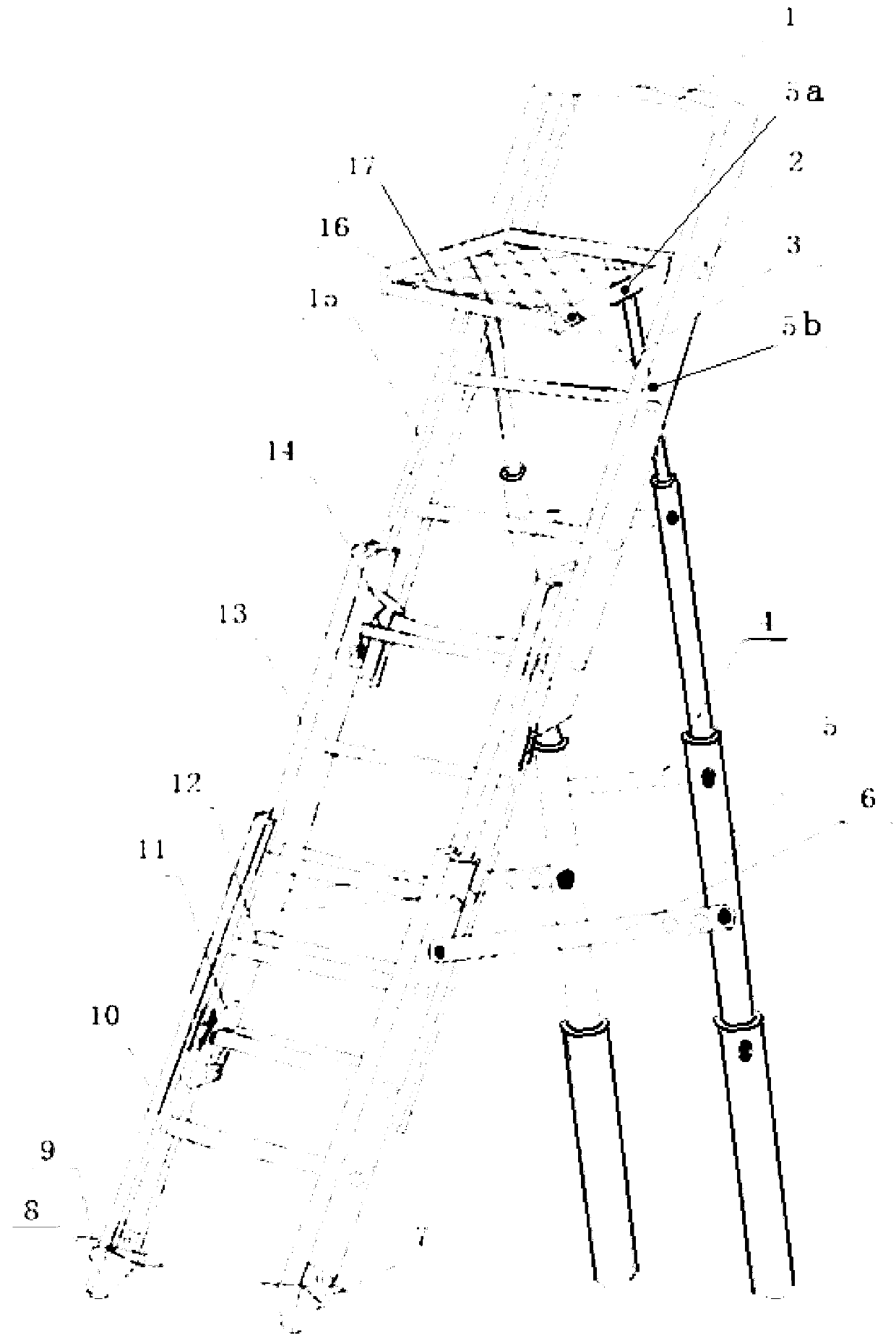

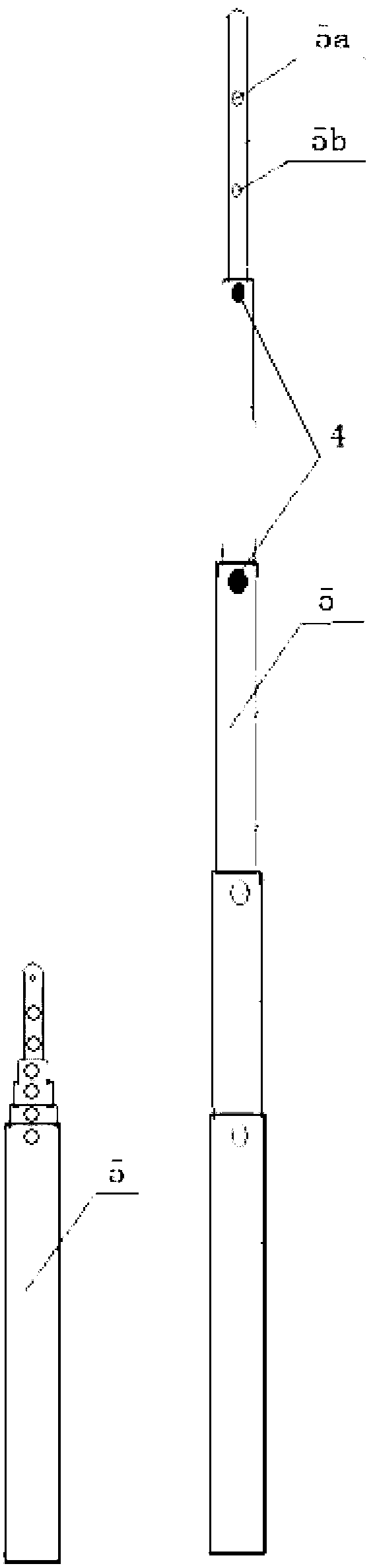

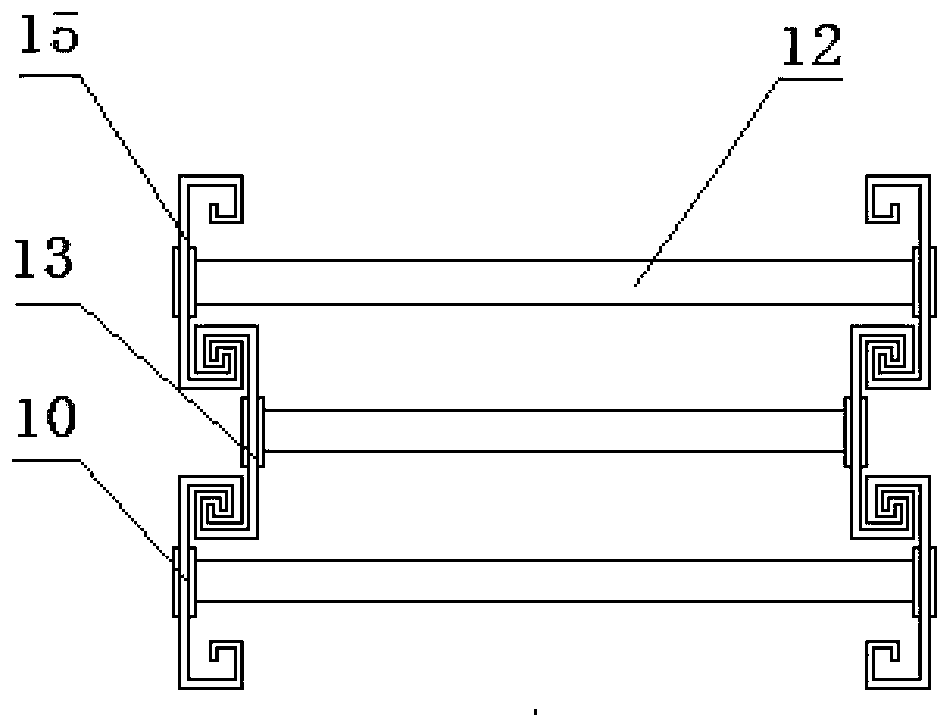

[0036] like figure 1 As shown, the outdoor work ladder includes a connecting bar 1, a fixed movable rod 2, a detachable supporting rod 3, a supporting connecting rod 4, a supporting frame 5, a fixed connecting rod 6, a fixed nail hole 7, a sole 8, and a sliding plate 9 , the lower ladder 10, the lower ladder fastening structure 11, the step bar 12, the middle ladder 13, the upper ladder fastening structure 14, the upper ladder 15, the metal frame 16, and the metal anti-skid plate 17. The upper ladder 15, the middle ladder 13, and the lower ladder 10 pass image 3 The shown side groove slides, and after sliding, between the upper ladder 15 and the middle ladder 13, and between the middle ladder 13 and the lower ladder 10, the lower ladder buckle structure 11 is engaged with the middle ladder step bar 12, and the upper ladder The fastening structure 14 is engaged with the step bar 12 of the upper ladder to achieve fixation, and the required height can be adjusted through the fa...

Embodiment 2

[0039] The difference from Example 1 is that it is made of square stainless steel material, the length of the upper ladder 15, the middle ladder 13, and the lower ladder 10 are all 2.2m, and the adjacent distance between the step bars 12 is 38cm; the number of support frame sections is 5 sections, Every joint length is 1.5m, and all the other operation modes are identical with embodiment 1.

Embodiment 3

[0041] The difference from Example 1 is that it is made of engineering plastic materials, the length of the upper ladder 15, the middle ladder 13, and the lower ladder 10 are all 2.0m, and the adjacent distance between the step bars 12 is 36cm; the number of support frame sections is 6 sections , the length of each section is 1.2cm, and all the other operating modes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com