A kind of preparation method of light diffusing agent for acrylic light diffusing plate

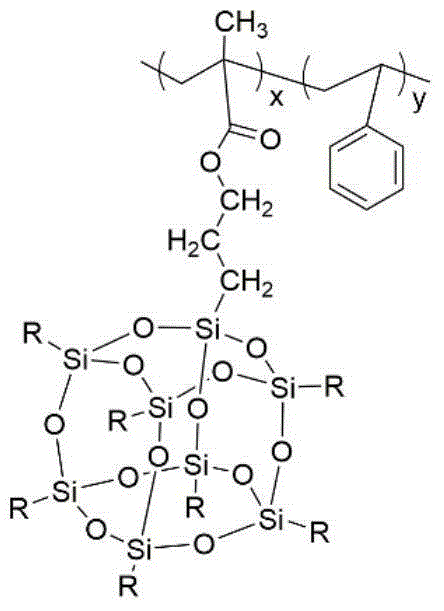

A technology of light diffusing plate and light diffusing agent, which is applied in the direction of diffusing elements, etc., can solve the problem of difficult to achieve the balance of haze and light transmittance, and achieve the effects of easy processing, good flame retardancy and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The objects, advantages and features of the present invention will be explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

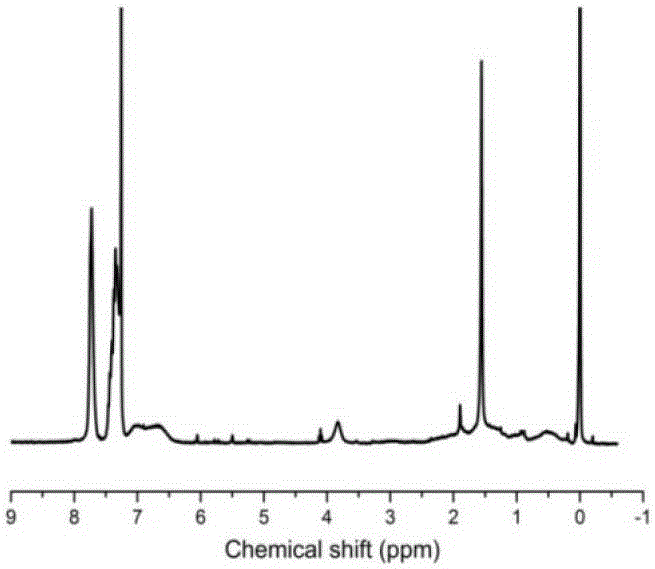

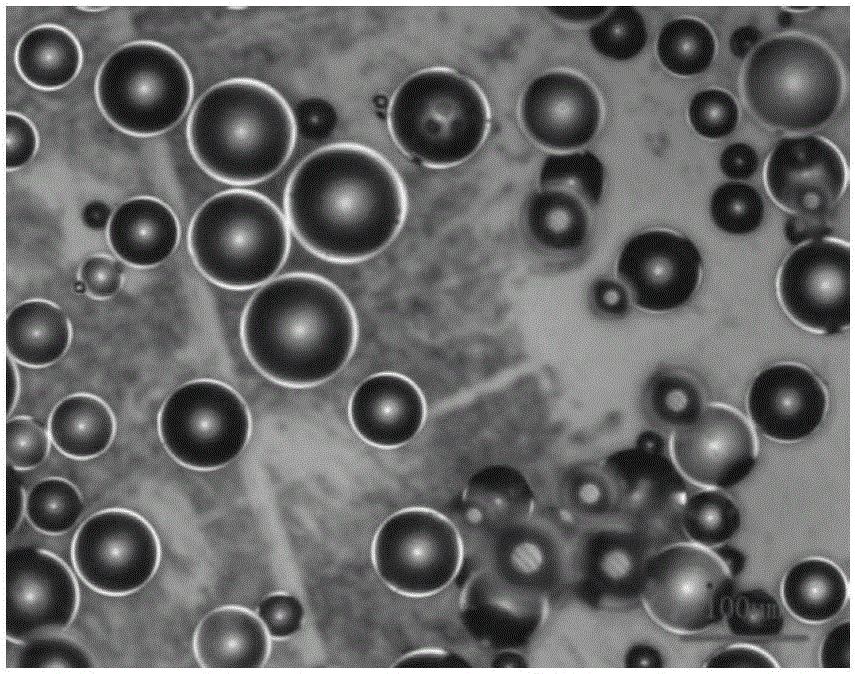

[0032] 1. Preparation of Light Diffuser

[0033] Add 3g of PVA1788 dispersant and 400ml of deionized water into the reactor, mechanically stir and dissolve at 50°C, keep warm for 20min, add 80ml of monomer mixture solution dissolved with 1.5g of initiator BPO, raise the temperature to 75°C, keep warm for 4h, then every 5 ℃ for 2 hours, until the temperature reached 95 ℃ for 2 hours, stop the reaction, repeat the steps of suction filtration, hot water washing, suction filtration, etc., and finally vacuum dry the sample at 60 ℃ for 12 hours to obtain light diffusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com