Multiple operating condition design method of centrifugal charging pump guide vane of nuclear power station

A design method and centrifugal technology, applied in the direction of non-variable-capacity pumps, pumps, pump components, etc., can solve problems such as difficult design of hydraulic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

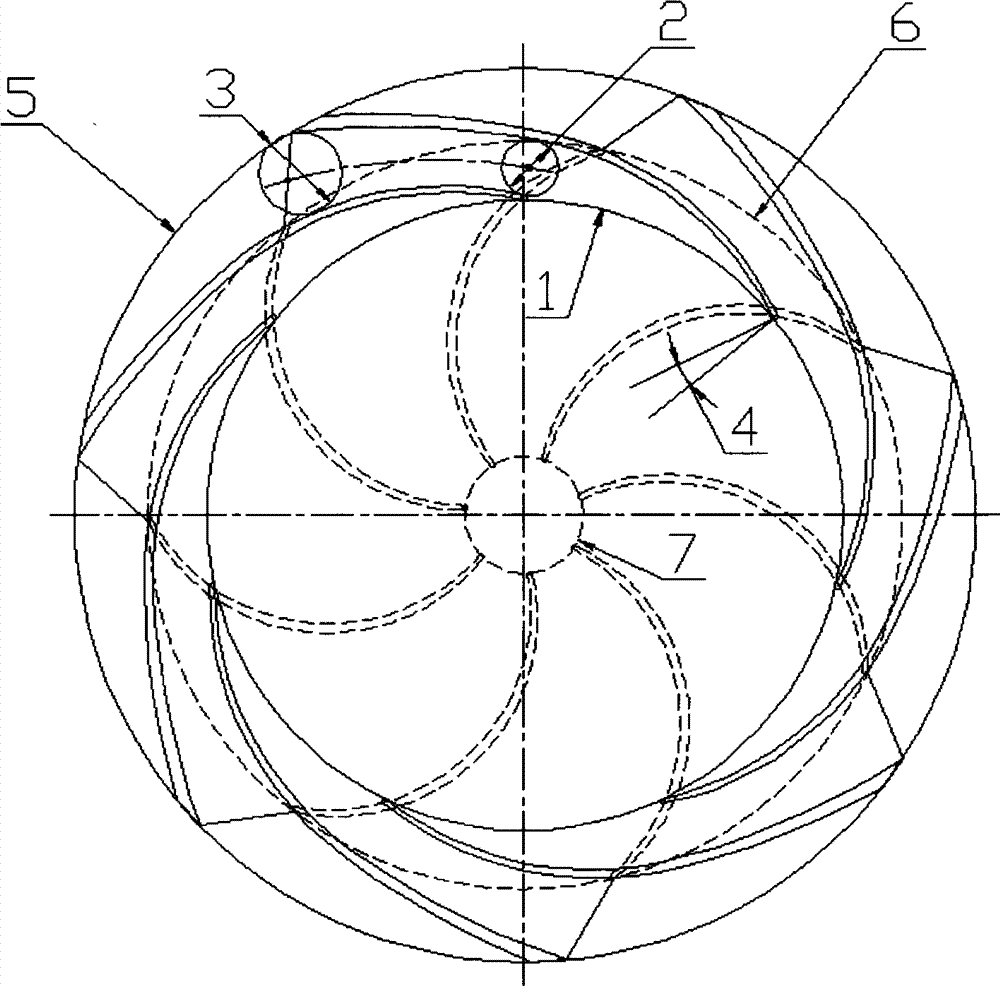

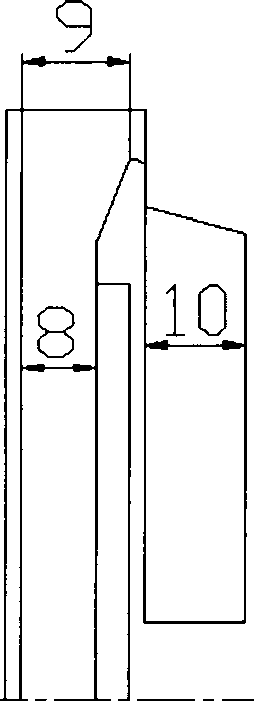

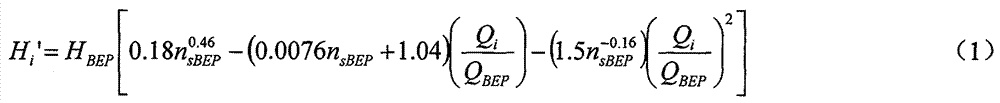

[0042] figure 1 and figure 2 Together determine the vane shape of this embodiment. The present invention adjusts the guide vane base circle diameter D through the following relations 3 (1) Height of guide vane throat a 3 (2), guide vane outlet height a 4 (3), guide vane inlet placement angle (4), guide vane outlet diameter D 4 (5), anti-guide vane inlet diameter D 5 (6), anti-guide vane outlet diameter D 6 (7), guide vane inlet width b 3 (8), guide vane outlet width b 4 (9) and anti-guide vane inlet width b 5 (10), make the performance of the charging pump of this embodiment satisfy the flow Q of the optimal efficiency working condition BEP , the head H of the optimal efficiency condition BEP , flow Q i , The head H of the i-th operating point obtained by the traditional design method i ', impeller speed n requirements.

[0043] H i ′ = H BEP [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com