Smoke denitration method of carbon monoxide (CO) heat recovery boiler of fluid catalytic cracking (FCC) device

A waste heat boiler and flue gas technology, which is applied in the field of selective catalytic reduction (SCR) denitration process, can solve the problems of not considering the close combination of denitration reactors, not considering ash removal and control of fugitive ammonia, etc., so as to save air Consumption, the effect of reducing air consumption, reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

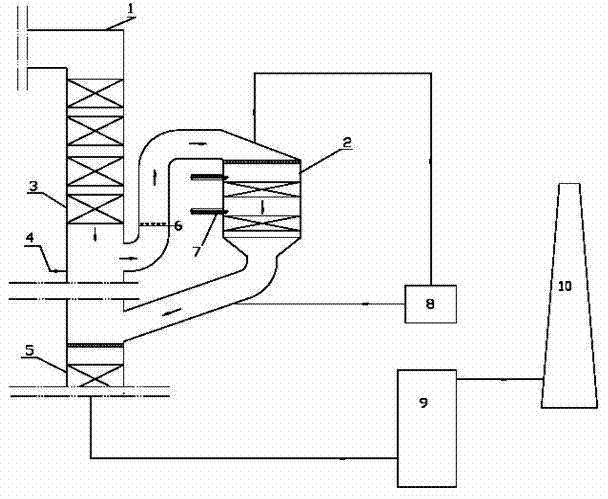

[0028]The invention provides a refinery catalytic cracking (FCC) flue gas denitrification process, which neither affects the NOx removal rate of the FCC flue gas nor affects the denitrification process flow of the normal operation of the boiler.

[0029] As shown in the figure, the flue gas from the CO waste heat boiler 1 is led out of the boiler from the outlet of the evaporation section 3, and the boiler dust is discharged from the CO boiler from the ash hopper 4. Mixing, the ammonia injection position is in the flue between the CO waste heat boiler and the denitration reactor. After the ammonia gas has been fully mixed with the flue gas, the NOx and NH that enter the catalyst bed of the denitrification reactor 2 3 Carry out denitrification reaction to generate N 2 and H 2 O, the purified flue gas at the outlet of the denitrification reactor 2 is sent to the inlet of the denitrification reactor 2 by the fan 8 at a circulation ratio of 0.1 to 1 to control the escape ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com