Intermetallic compound porous matrix composite filter element and preparation method thereof

An intermetallic compound, porous matrix technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problem of increasing cost and process complexity, reducing filtration effect and gas reduction rate, and reducing the specific surface area of the intermediate layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

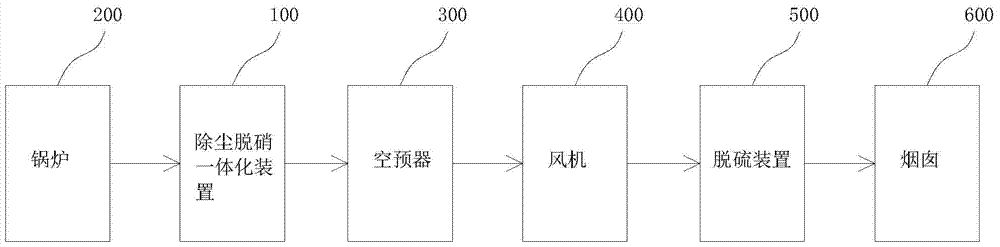

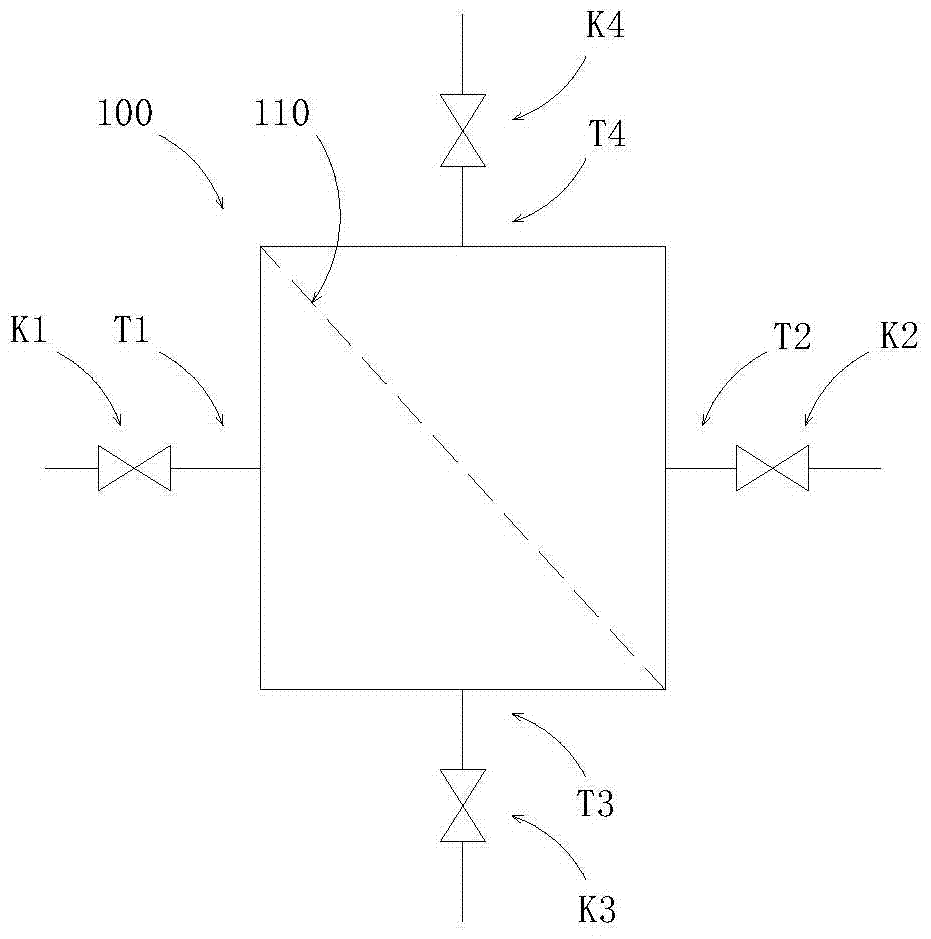

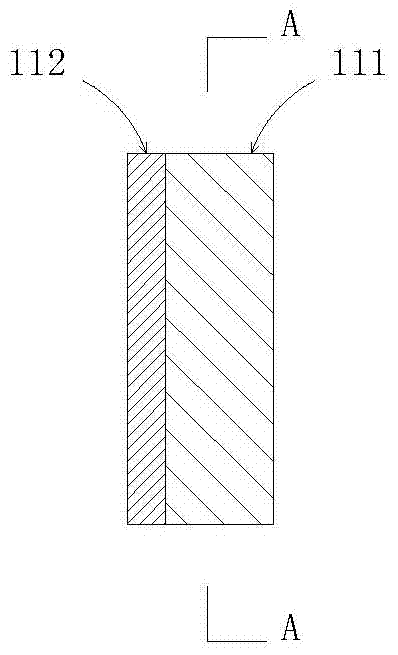

[0029] The preparation method of the intermetallic compound porous matrix composite filter element 110 includes the following steps: 1) preparing the porous matrix 111a; 2) configuring the sol as the material source of the intermediate layer 111c, then impregnating the sol into the porous matrix 111a, and then making The sol in the porous matrix 111a is gelled, and then the porous matrix 111a attached to the gel is heat-treated to convert the gel into nanoparticles, and then form the intermediate layer 111b; 3) configure the precursor solution of the catalytic active material, and then put The precursor solution is impregnated into the porous substrate 111a attached to the intermediate layer 111b, and then the porous substrate 111a attached with the precursor solution is heat-treated to form a catalytic active layer 111c on the intermediate layer 111b. And when the membrane layer 112 is arranged on the windward surface of the porous composite body 111, the following additional ...

Embodiment

[0034] An intermetallic compound porous matrix composite filter element 110 for integrated treatment of dust removal and denitrification of boiler furnace gas in a coal-fired power plant was prepared, and its dust removal and denitrification effect was tested. The preparation of the intermetallic compound porous matrix composite filter element 110 in this example, at first, adopts the formula of -100 mesh aluminum powder 30% (weight), -200 mesh iron powder 70% (weight), and sinters the aluminum system by powder metallurgy. Iron-aluminum intermetallic compound porous matrix 111a, the air flux of which is tested is 368m 3 / m 2 .h.kpa, the average pore diameter is 35μm, the tensile strength at room temperature is 90MPa, and the porosity is 42%. Image 6 and Figure 8 They are respectively 100 times and 500 times magnified photos of the porous matrix 111a under an electron microscope, where it can be observed that the surface of the pores of the porous matrix 111a is relatively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com