Detection and Classification Method for Surface Defects of Large Aperture Optical Components

A technology of optical components and classification methods, applied in the direction of optical testing flaws/defects, etc., can solve the analysis of difficult-to-absorb defects, non-absorptive defects cannot be applied, and non-absorptive defects are not sensitive, so as to improve the efficiency of inspection and increase the contrast ratio. , the effect of high recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

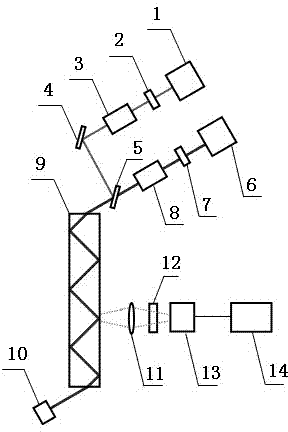

[0031] See figure 1 , a detection and classification device for surface defects of large-aperture optical components:

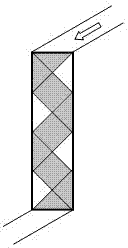

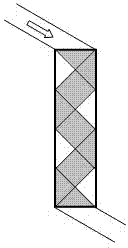

[0032] It includes a strong lighting source 1, a weak lighting source 6, a strong lighting beam switch 2 arranged at the rear end of the strong lighting light source 1, a weak lighting beam switch 7 arranged at the rear end of the weak lighting light source 6, and a strong lighting beam switch 7 arranged at the rear end of the strong lighting beam switch 2. Lighting beam shaping processing device 3, weak lighting beam shaping processing device 8 arranged at the rear end of weak lighting beam switch 7, high reflection mirror 4 arranged at the rear end of strong lighting beam shaping processing device 3, behind weak lighting beam shaping processing device 8 The dichroic mirror 5 whose reflective surface is arranged relative to the reflective surface of the high reflection mirror 4, the illumination beam absorbing device 10 arranged on the exit side of the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com