A pressing mold for automobile halogen lamp

A technology for pressing molds and halogen lamps, which is applied in the direction of incandescent lamps, incandescent lamp parts, electrical components, etc., which can solve the problems of short service life, explosion of lamp tube wall, and difficulty in divergence, so as to improve service life and increase inrush The effect of pressure and preventing bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

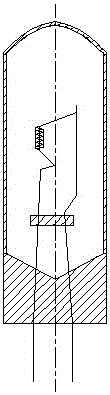

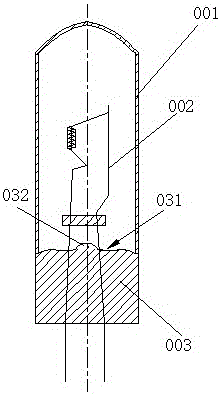

[0025] Embodiment 1: A halogen lamp for automobiles, including a lamp tube 001 and a filament 002 arranged in the lamp tube 001. The two pins of the filament 002 protrude from the lower end of the lamp tube 001 by welding the sealing part 003, and the upper end of the welding sealing part 003 The connection with the filament 002 is a smooth connection surface 031, and there are bumps 032 between the pins of the filament 002 on the connection surface 031.

Embodiment 2

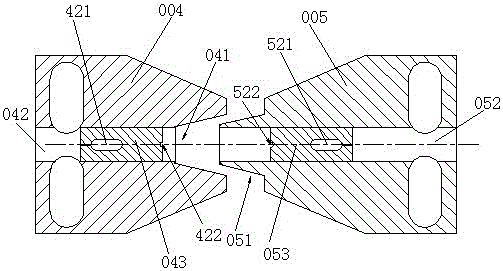

[0026] Embodiment 2: A mold for pressing a halogen lamp of an automobile, including two butted modules (004, 005) on the left and right sides, the butted ends of the left and right modules (004, 005) are respectively provided with a matching groove 041 and a bump 051, The protruding length of the bump 051 is shorter than the depth of the groove, and the butt joint forms a closed notch 006. The width of the closed notch 006 is 2.8~3.2mm. The grooves of the left and right modules (004, 005) 041 and bump 051 are arranged in the center of the module, and the center of the upper surface of the left and right modules (004, 005) has a bar-shaped chute (042, 052) that runs through each other, and each chute of the left and right modules (004, 005) (042, 052) are equipped with a strip slider (043, 053) that can be inserted into it to slide left and right, and the sliders (043, 053) are provided with through holes for fastening the slider and the chute bolt (421, 521), the butt ends of ...

Embodiment 3

[0027] Embodiment 3: Referring to Embodiment 2, the groove 041 is a two-layer stepped notch, the bump 052 is a two-layer stepped bump, the center of the upper groove bottom has a gap, and the center of the upper bump has a corresponding The gap, the groove 041 and the bump 042 are butted to form a stepped closed notch 006, the width of the upper groove is 1.8~2.4mm, and the width of the lower groove is 2.8~3.2mm.

[0028] serial number Closed notch width (mm) The distance between the butt joint surfaces of two sliders (mm) Atmospheric pressure (mpa) service life (h) Example 1 2.8 1.8 110 700 Example 2 2.9 2.0 90 600 Example 3 3.0 2.2 70 650 Example 4 3.2 2.4 50 660

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com