A motor and pump barrier fluids pressure regulation system in a subsea motor and pump module

A technology for regulating systems and motors, applied in the field of pressure systems, can solve problems such as increased response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

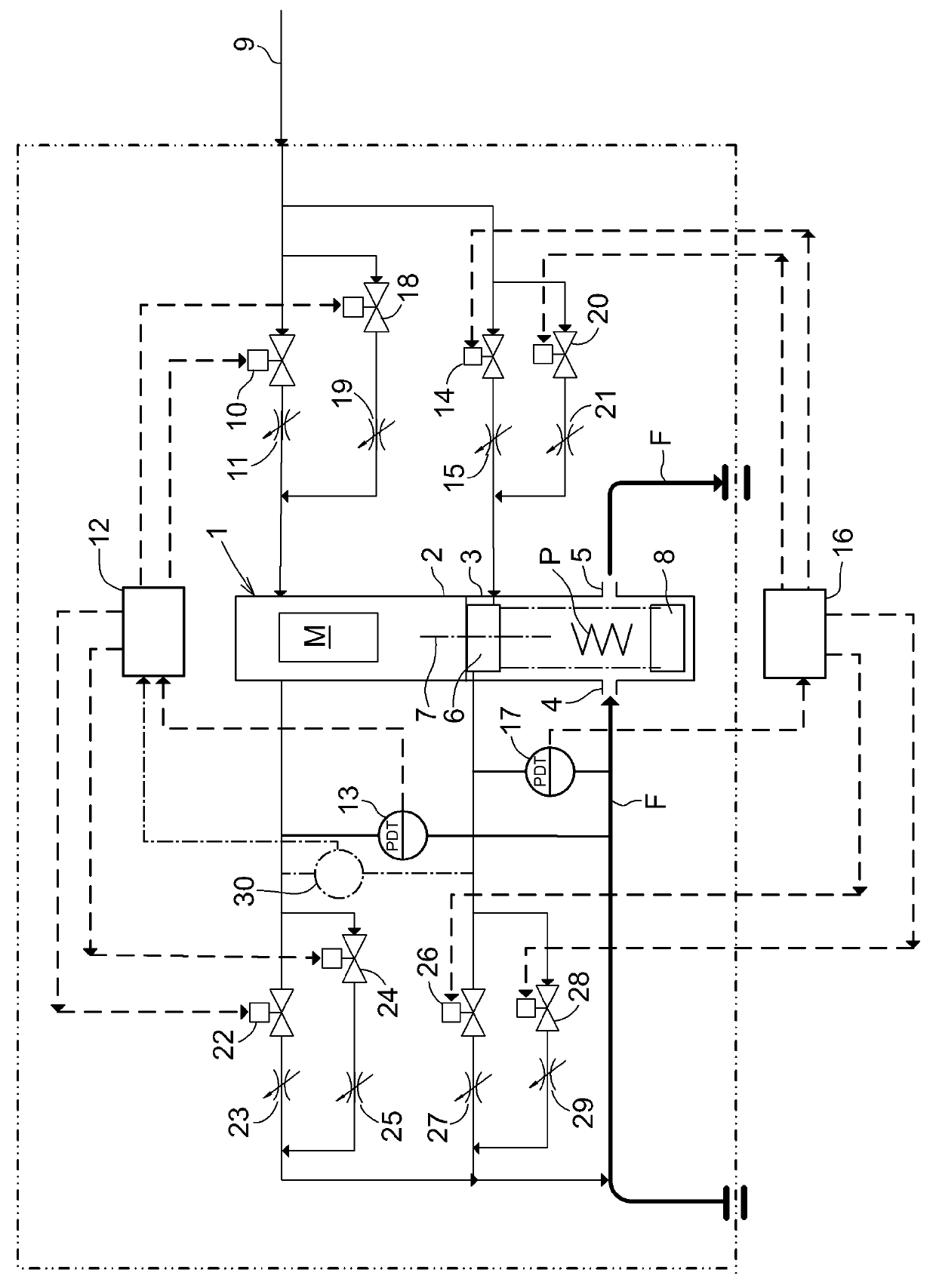

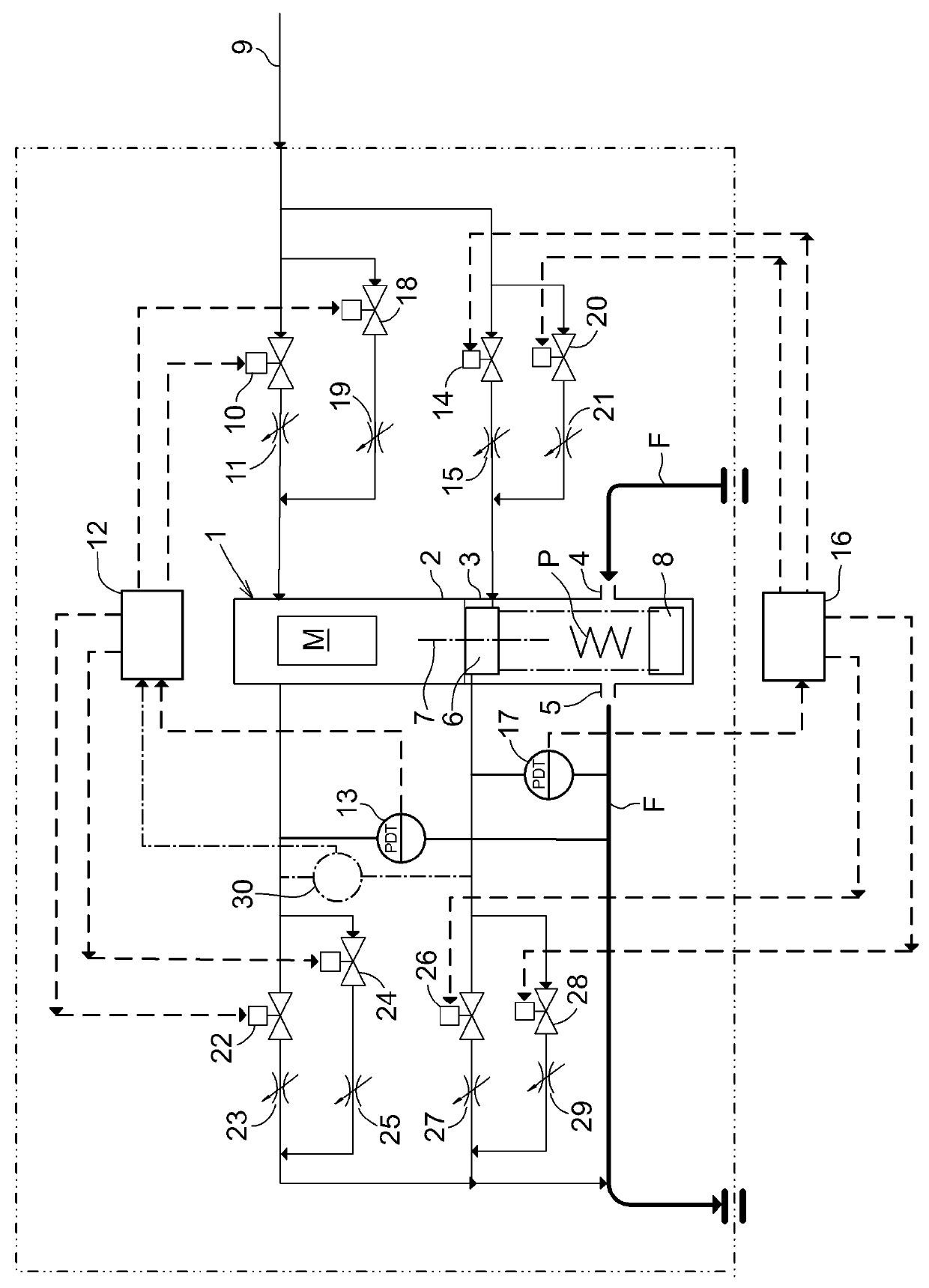

[0037] In the following, reference will be made to the accompanying drawings ( figure 1 and figure 2 ) describe preferred embodiments of the present invention in more detail. In the figures, the subsea motor and pump module comprises a motor / pump assembly 1 to which motor barrier fluid and pump barrier fluid are supplied from an external source of hydraulic fluid.

[0038] Since the present invention is not limited to any particular type or model of motor / pump assembly, but is in fact also applicable to various motor / pumps familiar to the skilled person involved in the transfer of process fluids from subsea hydrocarbon production configuration, the interior of the motor / pump assembly 1 need not be discussed in detail. Typically, the motor / pump assembly includes a motor M enclosed in a pressurized watertight enclosure or motor housing 2 , and a pump rotor assembly P enclosed in a pump housing 3 . The motor driving the pump is usually an electric motor, but other drive units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com