Material throwing device and throwing method with high-energy liquid explosion fixed-point blasting system

A material and liquid explosion technology, which is applied in the field of throwing materials, can solve the problems of damaged materials, complicated operation of cannons, lack of practicability, etc., to achieve the effect of simplifying production and operation technology and liberating agricultural labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

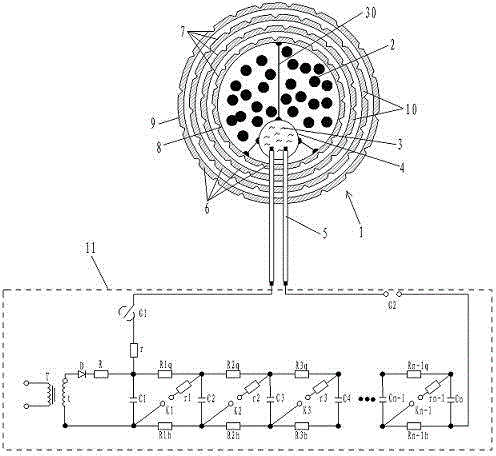

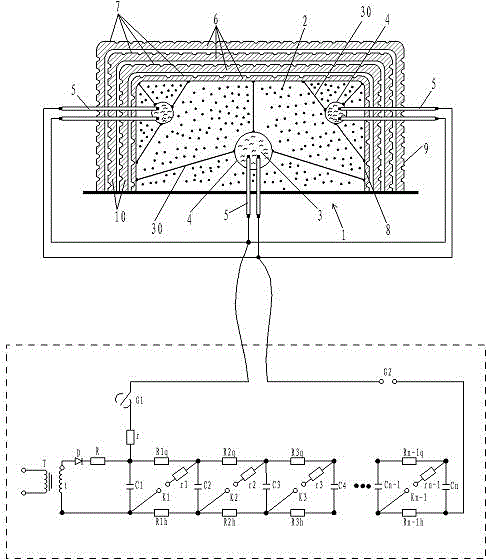

[0054] Embodiment 1. Material throwing device with high-energy liquid explosion fixed-point blasting system

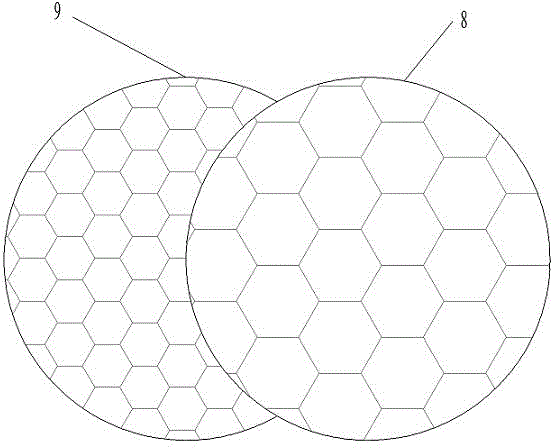

[0055] Such as figure 1 Put ordinary water into a rubber bag, put into the discharge ends of two mutually insulated electrodes 5 respectively, and seal the rubber bag to make a liquid sac 4 with electrodes. Make the shell of material airtight container 1 with cardboard material, leave an opening that can be loaded into to be thrown material 2 such as seed, fertilizer, pesticide, and the liquid bag 4 that can be packed into band electrode during making, install from the opening of liquid bag 4 Enter the liquid bag 4 with electrodes and the material 2 to be thrown; the liquid bag 4 and the inner wall of the material airtight container 1 are also connected at three positions with three soft ropes 30, and the liquid bag 4 is fixed in the material airtight container 1 without any displacement. Place the ends of the two mutually insulated electrodes 5 connected to the imp...

Embodiment 2

[0065] Embodiment 2. Material throwing device with high-energy liquid explosion fixed-point blasting system

[0066]As in embodiment 1, the only difference is that in the impulse voltage generator 11, the voltage of the high-voltage secondary coil t of the transformer T is 15 kV, the current limiting resistor is 62 ohms, and the isolation resistors R1q, R2q, R3q...Rn-1q are all It is 82 ohms, the buffer resistance r is 82 ohms, the capacitors C1, C2, C3, C4... Cn are each the same, the withstand voltage of the capacitor is 20 kV, and the capacity of the capacitor is 6.8 microfarads.

Embodiment 3

[0067] Embodiment 3, a material throwing device with a high-energy liquid explosion fixed-point blasting system

[0068] As in embodiment 1, the only difference is that in the impulse voltage generator 11, the voltage of the high-voltage secondary coil t of the transformer T is 13 kV, the current limiting resistor is 40 ohms, and the isolation resistors R1q, R2q, R3q...Rn-1q are all is 40 ohms, the snubber resistor r is 40 ohms, the capacitors C1, C2, C3, C4...Cn are each the same, the withstand voltage of the capacitor is 20 kV, and the capacity of the capacitor is 4.0 microfarads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com