Trunk lid lock stiffening plate raising punching mould

A trunk lid lock and reinforcement plate technology, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long processing cycle, low production efficiency, high mold manufacturing cost, etc., and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

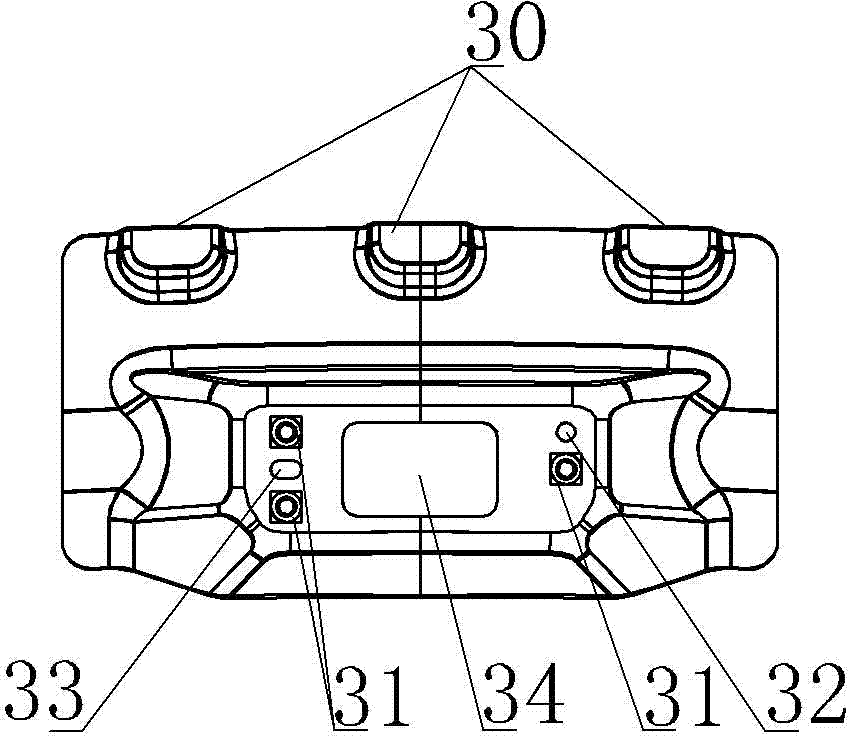

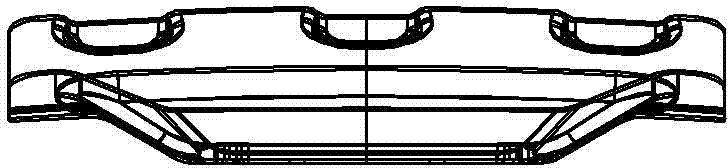

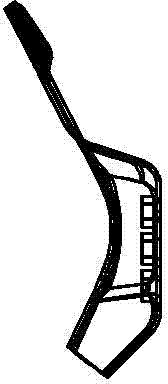

[0017] See Figure 4 to Figure 7 , a trunk lid lock reinforcement plate embossing and punching die, which includes an upper template 1 and a lower template 2, an upper mold structure is installed under the upper template 1, a lower mold structure is installed on the lower template 2, and a mold is installed at the bottom of the lower template 2. Feet 8, the structure of the upper mold includes a convex upper insert 18, a convex punch 16, a punching upper insert 20 and punches 11, 12, 13, 17, and the convex punch 16 is installed on the convex upper insert In the part 18, the upper ends of the punching punches 11, 12, 13, 17 are installed in the punching upper insert 20, and the embossing upper insert 18 is located on the longitudinal upper side of the punching upper insert 20; the lower die structure includes the embossing lower The insert 15 and the punching lower insert 10, the punching lower insert 10 is located on the longitudinal lower side of the punching lower insert 15;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap