Butterfly valve assembly auxiliary tool

An assembly aid and tool technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of economic loss, affect the appearance, low efficiency, etc., and achieve the effect of reducing labor intensity, avoiding economic losses, and eliminating unnecessary damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

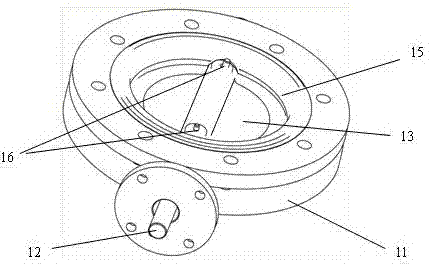

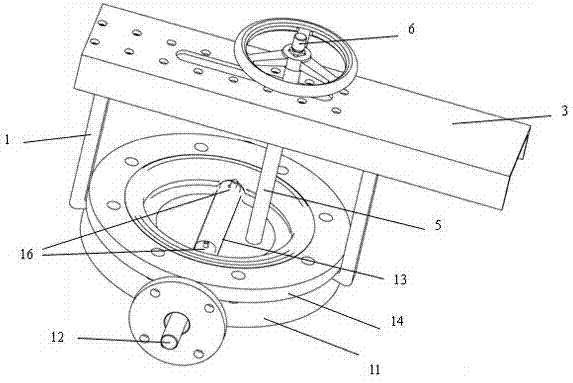

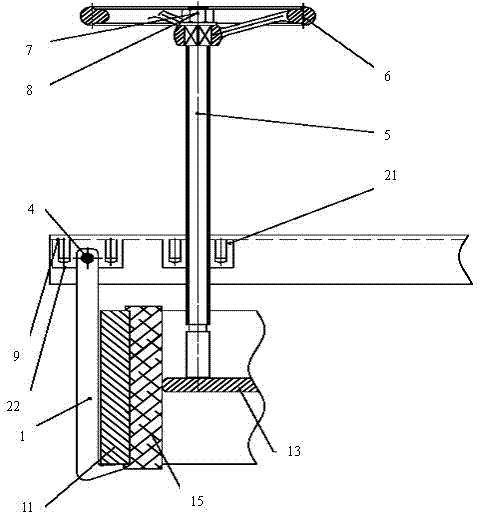

[0015] based on the following figure 2 and image 3 , specifically explain the preferred embodiment of the present invention.

[0016] like figure 2 and image 3 As shown, the present invention provides a butterfly valve assembly auxiliary tool, which tool includes a beam 3, a hook bell 22 arranged at both ends of the beam, a rod bell 21 arranged on the beam, a hook 1 for connecting the hook bell 22, and a Cross bar with the bar 5 of live bell 21 and the hand wheel 6 that is connected with bar 5;

[0017] Fix with pin 4 between described hook 1 and hook live bell 22;

[0018] Also set fixture 9 on the hook live bell 22, this fixture 9 is a bolt and a washer;

[0019] Fix with bolt 8 and washer 7 between described rod 5 and handwheel 6;

[0020] Several different installation positions are reserved on the beam 3. According to the size of the valve body flange of the butterfly valve, determine the fixed position of the hook live bell 22 on the beam 3. The hook 1 hooks th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com