Installation assembly for oil filling pipe cap lock cylinder

A technology of refueling pipe and lock cylinder, applied in the direction of anti-theft vehicle accessories, power unit, transportation and packaging, etc., can solve the problems of occupying body space, inconvenient refueling, loss of the environment for car owners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

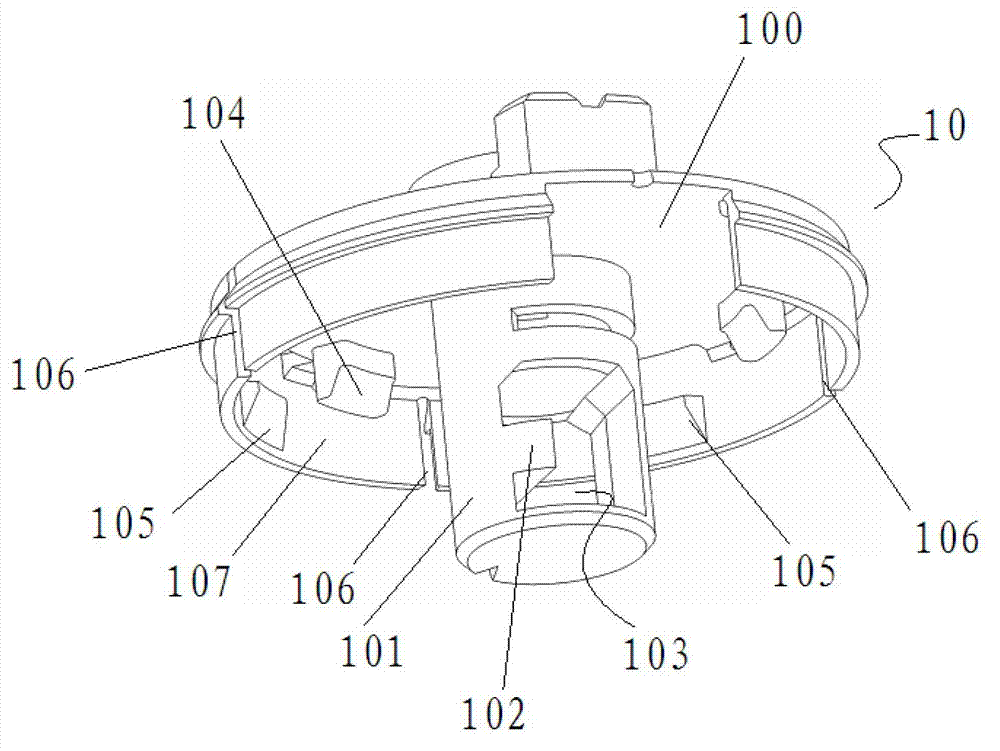

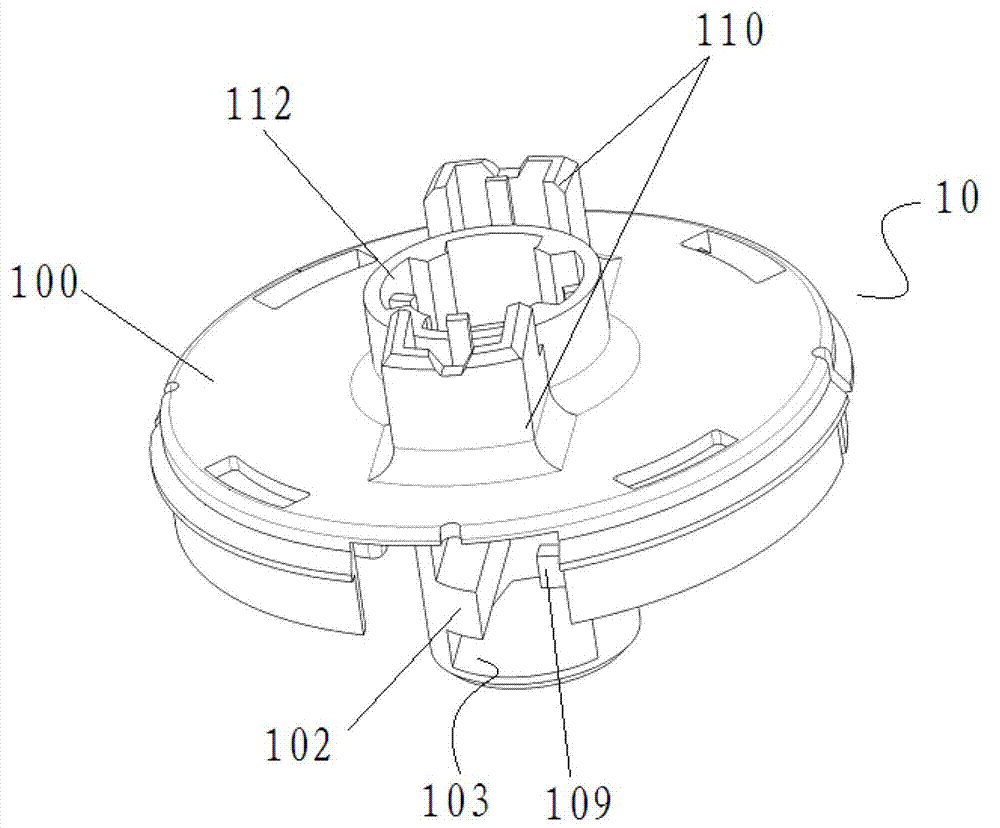

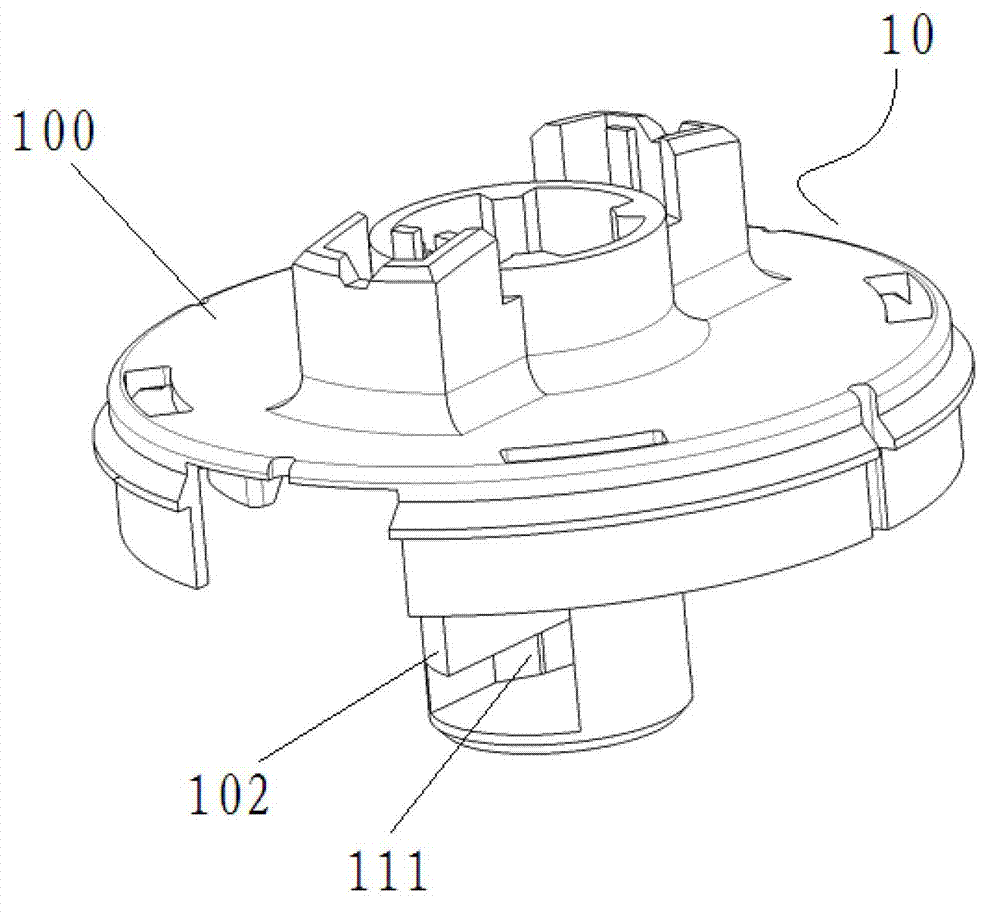

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to Figure 1-Figure 8 , Figure 17 , a lock cylinder installation assembly of the present invention includes a lock cylinder seat 101 having a lock cylinder groove, and a lock cylinder 1 located in the lock cylinder groove and relatively rotating with the lock cylinder seat 101, the lock cylinder seat 101 of the present invention is A hollow cylindrical shape, closed at one end and used to accommodate a lock cylinder at the other end. The structure in which the lock cylinder cooperates with the key belongs to the prior art, and will not be described in detail here. In the lock cylinder 1 of the present invention, an eccentric push post 1a is provided at a position where the bottom end deviates from the center of the circle.

[0032] Below the side wall of the lock cylinder seat 101, there is a deadbolt groove 103 that at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com