A vane type hydraulic machine

A hydraulic machinery and vane technology, applied in the field of hydraulic machinery, can solve the problems of unreliable performance, easy fatigue failure of springs, limited life, etc., to achieve reliable performance, avoid fatigue failure damage, and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

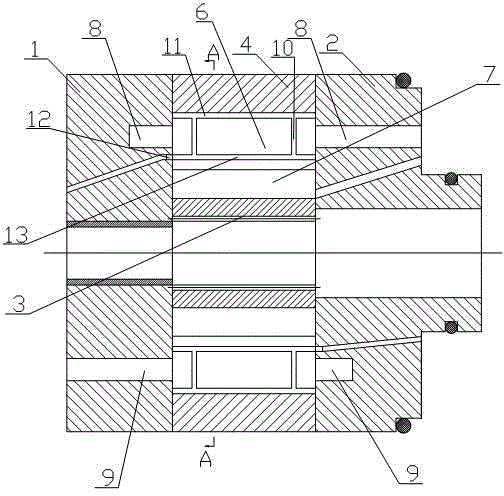

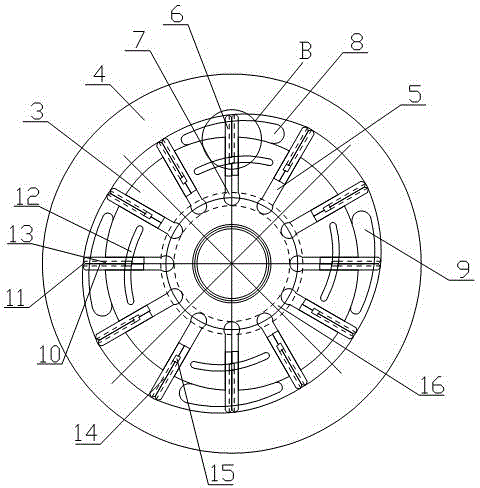

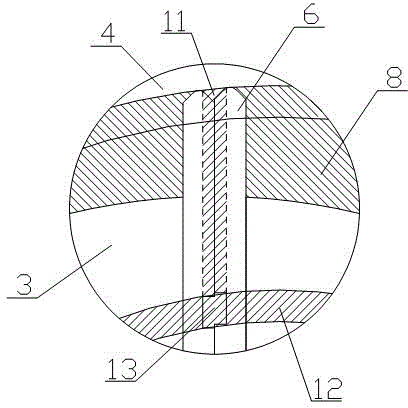

[0027] exist figure 1 In the shown embodiment, a vane-type hydraulic machine, the vane-type hydraulic mechanism may be a hydraulic pump or a hydraulic motor, including two front and rear shells and shafts, and the front and rear two shells are provided with High-pressure port, low-pressure port, inlet port, outlet port, fluid inlet port, fluid outlet port, and the interface connected to the external pressure fluid. Sealing devices are provided between the components of the hydraulic machine to protect the inner part of the sealed cavity. body. The core part of the hydraulic machine includes the oil inlet side plate 1, the oil outlet side plate 2, the rotor 3, the stator 4 and the blade 6 arranged in the rotor groove 5. The blade 6 and the bottom of the rotor groove 5 form a bottom cavity 7, and the oil inlet The side plate 1 and the oil outlet side plate 2 are respectively provided with a high-pressure chamber 8 and a low-pressure chamber 9, a fluid channel 10 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com