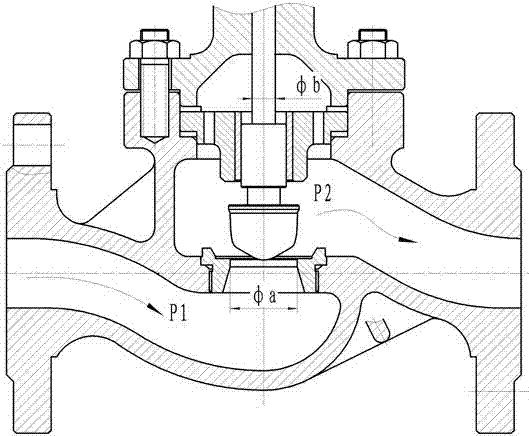

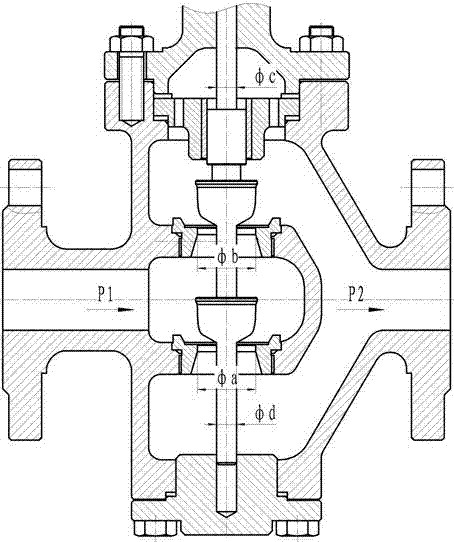

Energy-saving balanced high-pressure single seated valve

A single-seat valve, balanced technology, applied in the direction of the valve details, valve device, valve shell structure, etc., can solve the problems of low sealing level, complex structure inside the valve, high processing and assembly precision requirements, and reduce production costs, structure Simple and smooth effects with a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

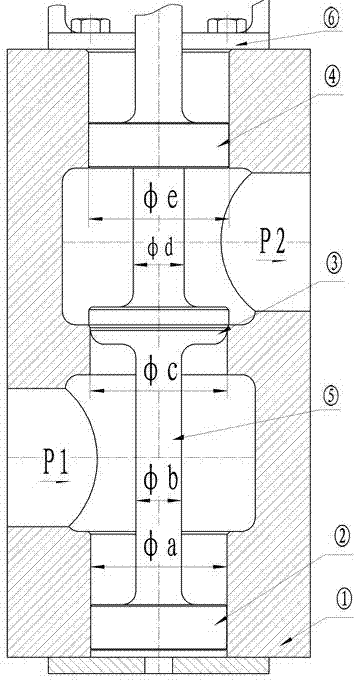

[0018] like image 3 As shown, the present invention is an energy-saving balanced high-pressure single-seat valve, including a valve body ①, a valve cover ⑥, a valve stem ⑤, a valve core ③ and a valve seat, and the valve stem ⑤ passes through the valve cover ⑥ and extends into the interior of the valve body ① , the valve core ③ is set in the middle of the valve stem ⑤, and the inner wall of the valve body ① has a valve seat matched with the valve core ③, which is the basic structure of the high pressure valve. In this specific embodiment, the valve body ① of the high-pressure valve is processed by an integral forging, and it can also be in other forms. The valve body ① is in the shape of a sleeve, and the top of the valve body ① is provided with an end cover - the bonnet ⑥, and the bonnet ⑥ is provided with a hole for the valve stem ⑤ to extend into, and the top is connected to the bracket and other components; the bottom of the valve body ① is fixed The connecting baffle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com