Fully automatic gas recovery and filling device and method

A gas recovery and fully automatic technology, applied in refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of air pollution, no cleaning, damage to automobile air conditioners, etc., achieve standardized operation, reduce difficulty requirements, and prevent accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

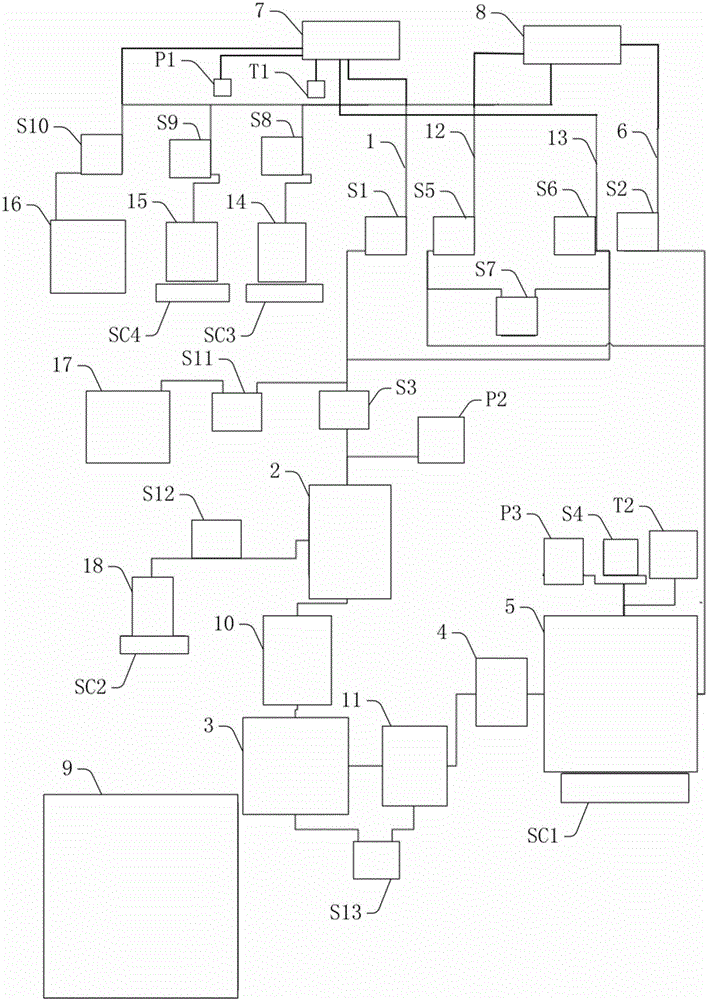

[0079] An embodiment of the fully automatic gas recovery charging device and method of the present invention is provided below.

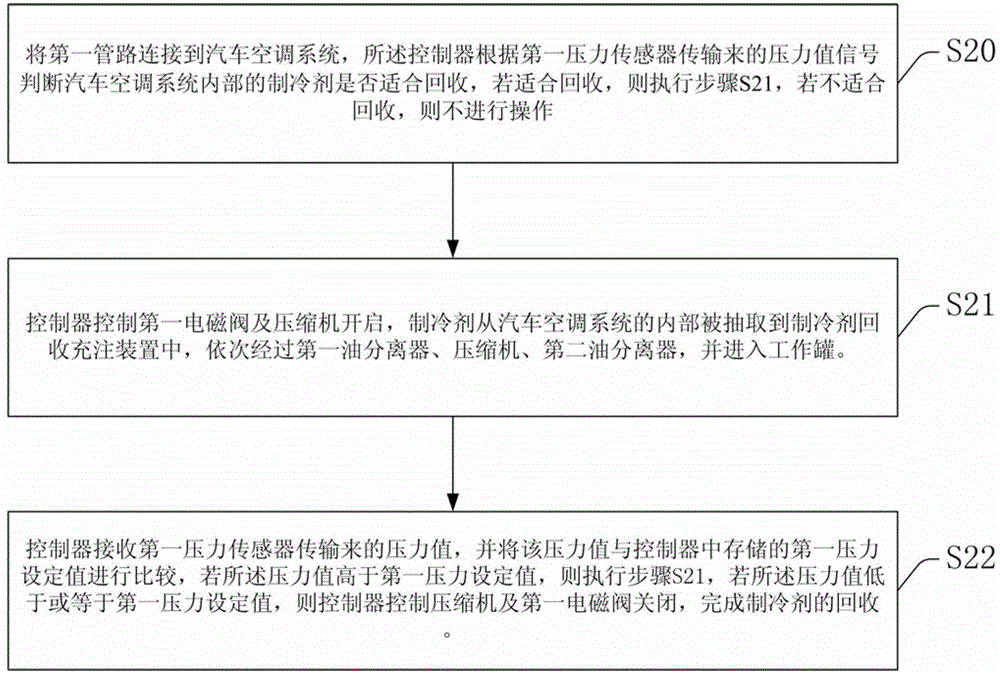

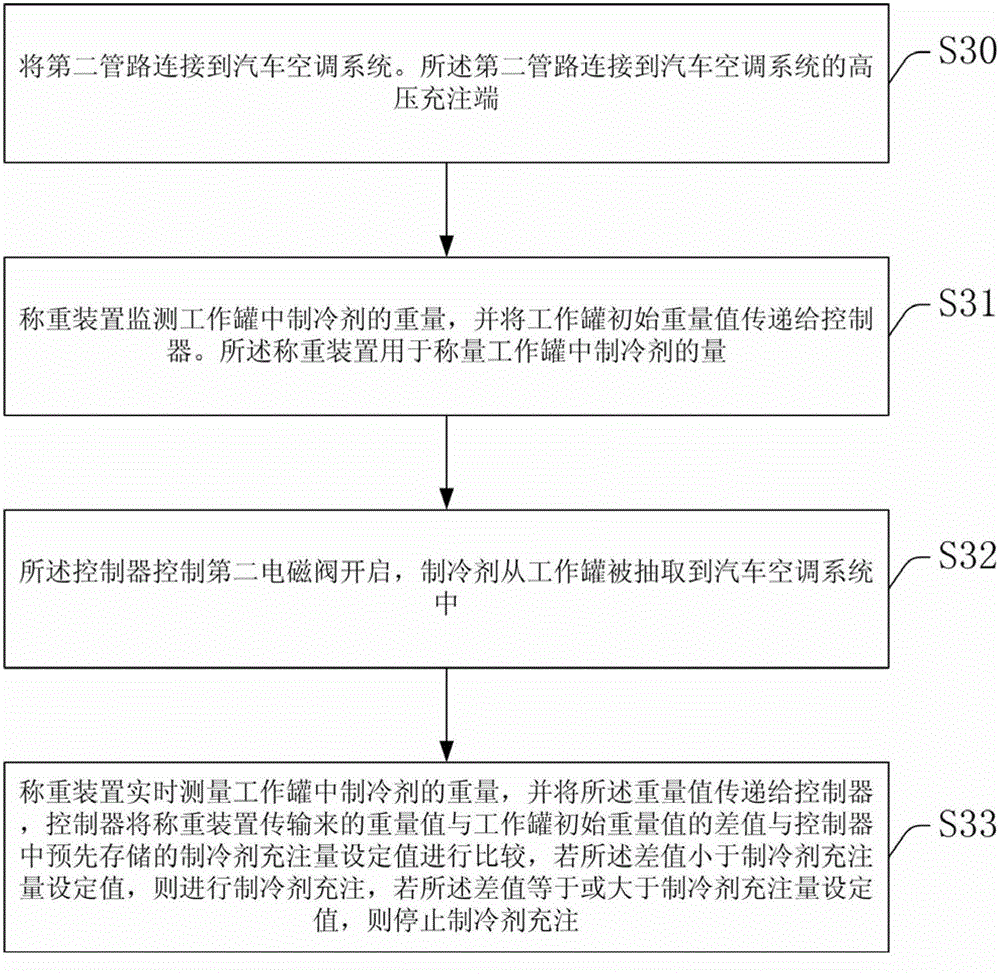

[0080] When the fully automatic gas recovery charging device is connected to the automobile air conditioning system, without any manual operation, the first pressure sensor and the first temperature sensor will automatically feed back the pressure and temperature of the refrigerant in the automobile air conditioning system, through the user panel of the controller. show. At the same time, the controller uses these two signals to determine whether the state of the refrigerant is suitable for recovery and purification through internal calculation. Once the user confirms the recovery and purification, and enters the car model into the controller, the controller turns on the compressor and the first solenoid valve to form a pressure difference in the local system and lead to the suction condition of the refrigerant.

[0081] In this process, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com