Method and device for measuring ultrasonic standing wave suspension force

A measuring device and acoustic levitation technology, which is applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problem of no quantification of the levitation ability of the acoustic levitator, and achieve the effect of simple structure, easy operation, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

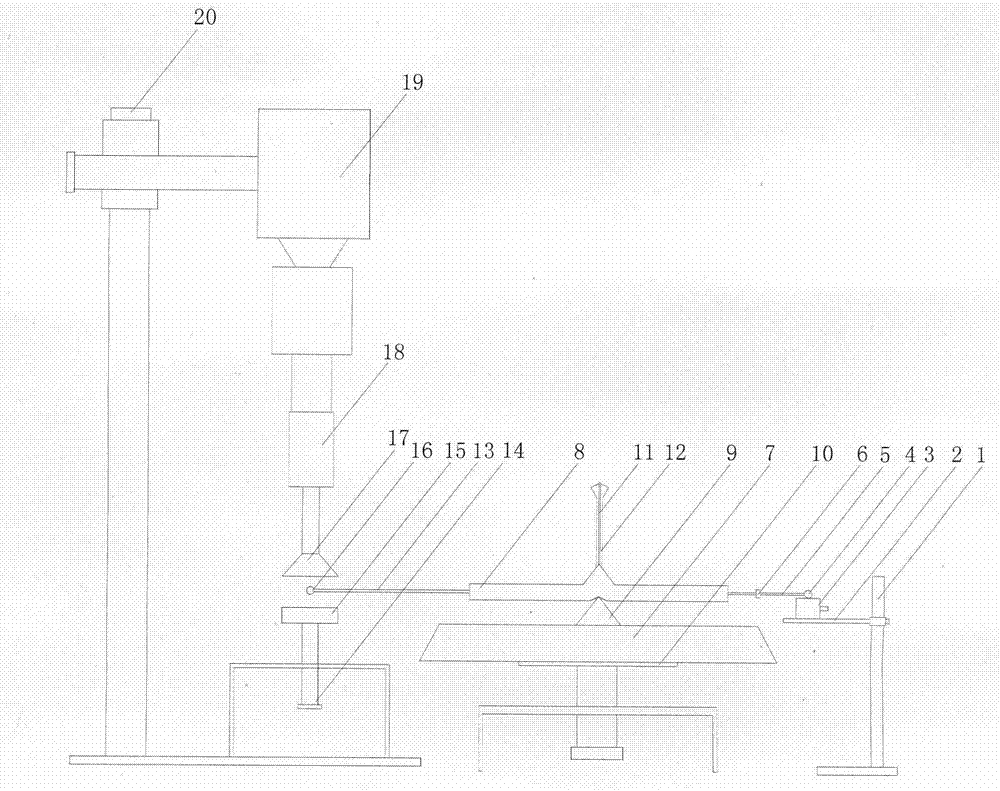

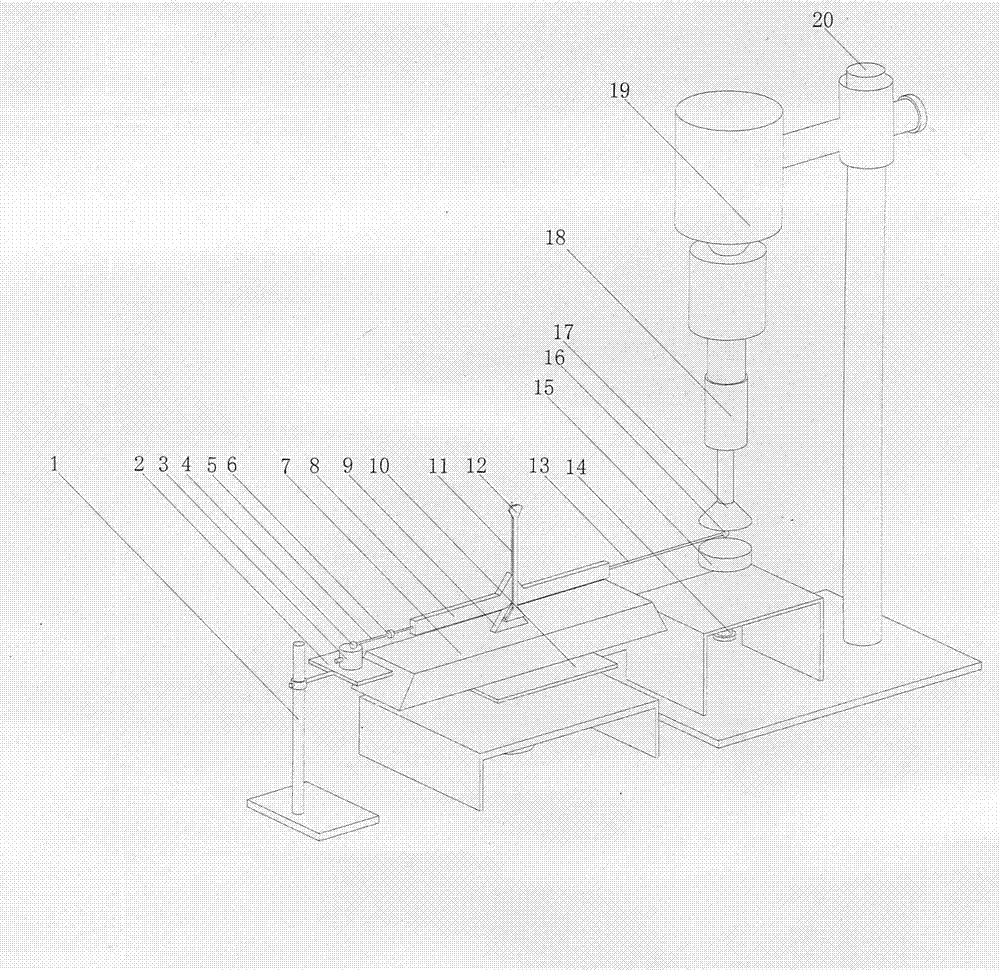

[0016] This device is a measuring device for ultrasonic levitation force, and its structure refers to figure 1 and figure 2 . The beam 8 is placed on the knife seat 9, the knife seat 9 is fixedly connected to the base 7, the threaded rod 5 and the thin rod 13 are all fixed on the cross beam 8, and the leveling nut 6 can rotate left and right on the threaded rod 5 through threaded connection, The small ball 4 and the small ball 16 are threadedly connected with the threaded rod 5 and the thin rod 13 respectively, and the height of the load cell 3 is adjusted by adjusting the liftable support platform 2, and the load cell 3 is in contact with the small ball 4. There is no effect of force. In this way, a complete ultrasonic levitation force measuring device is formed.

[0017] When using this device to measure the ultrasonic standing wave suspension force, the specific steps are as follows:

[0018] 1. Place the small ball 16 between the ultrasonic transmitting end 17 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com