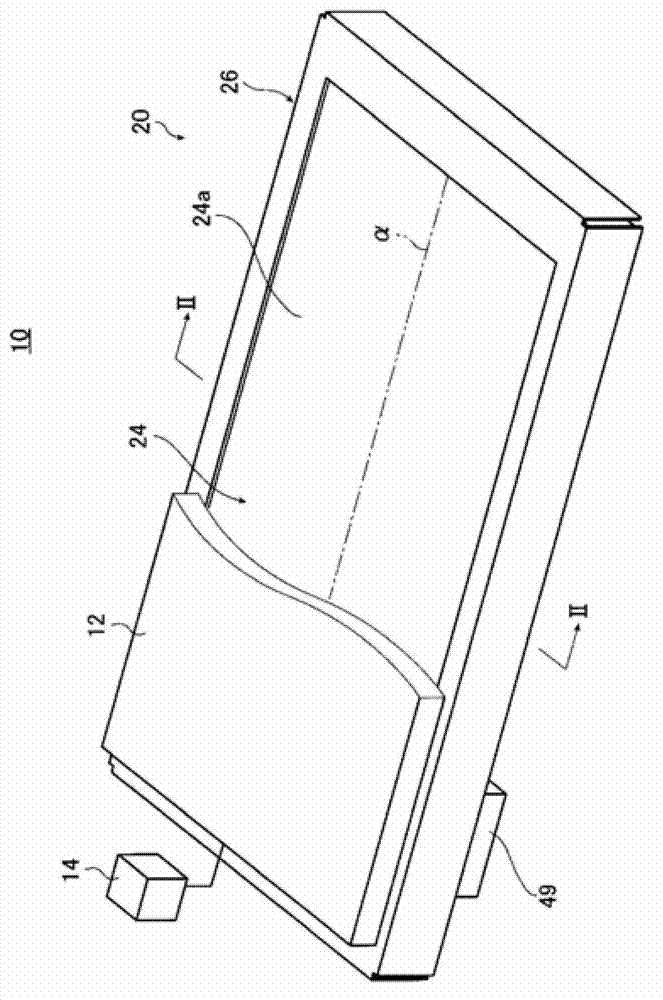

Light guide plate, planar lighting device, and liquid crystal display device

A technology of light guide plate and light exit surface, applied in the field of light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

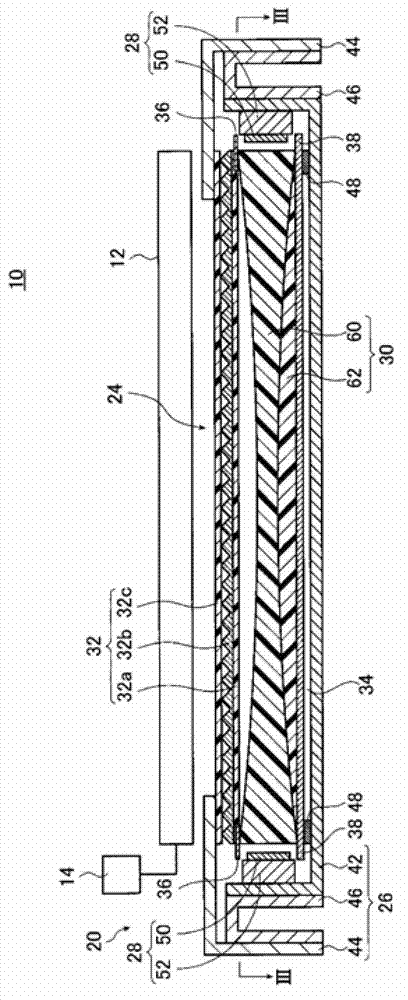

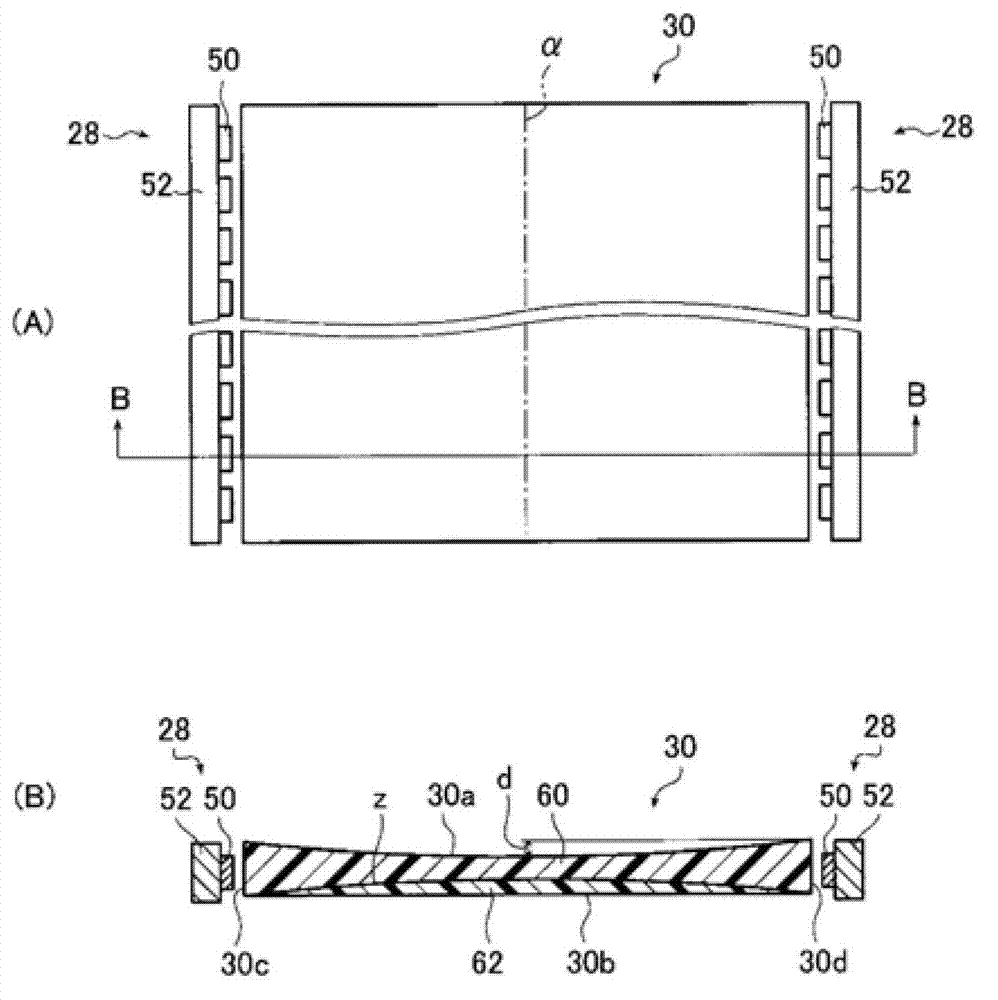

example 1

[0218]The light guide plate 30 when the screen size corresponds to 42 is used as Example 1. Specifically, a light guide plate whose length from the first light incident surface 30c to the second light incident surface 30d is set to 545 mm and whose length from the light exit surface 30a to the back surface 30b at the bisector α is The length until the length, that is, the thickness D of the thinnest part is set as 2.56mm, the thickness of the first light incident surface 30c and the second light incident surface 30d, that is, the thickness of the thickest part is set as 3.0mm, and the thickness of the first light incident surface 30c and the second light incident surface 30d is set as 3.0mm. The length from the light exit surface 30a to the boundary surface z at the bisector α of the first layer 60, that is, the thickness D1 of the first layer 60 at the thinnest part of the first layer 60 is set to 2.12 mm, and the second The length from the boundary surface z to the rear surf...

example 2

[0237] As Example 2, the following light guide plate 80 is used. This light guide plate 80 is a light guide plate with the same shape as Example 1 and a screen size of 46, such as Figure 12 As shown, the boundary surface z between the first layer 60 and the second layer 62 is such that the second layer 62 enters the first light from the light exit surface 30a (ie, the central part of the light exit surface) at the bisector α. The surface 30c and the second light incident surface 30d change continuously so that they become thinner, and continue to become thicker again toward the light exit surface 30a near the first light incident surface 30c and the second light incident surface 30d. changed. At this time, the synthetic particle concentration is obtained using the reverse deviation concentration, and the thicknesses (shape of the boundary surface z) of the first layer 60 and the second layer 62 are obtained from the obtained synthetic particle concentration.

[0238] That is...

example 3

[0250] As example 3, Figure 12 The light guide plate 80 shown is a light guide plate when the screen size is 32, and the curvature radius R of the concave and convex curved surfaces of the boundary surface z is changed y1 , R y2 , and the particle concentrations of the first layer 60 and the second layer 62 are measured.

[0251] Specifically, the following light guide plate is used as Example 3. The length of the light guide plate from the first light incident surface 30c to the second light incident surface is set to 413mm, and the first light incident surface 30c and the second light incident surface 30d The thickness, that is, the thickness D2 of the thickest part is set to 3mm, the amount of depression d is set to 0.5mm, the radius of curvature of the light exit surface 30a is set to 42500mm, and the thickness D3 of the second layer 62 on the first light incident surface The thickness D4 of the thinnest part of the second layer 62 was 0.5 mm, and the thickness D5 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com