Edible fungus automatic production line

An automatic production line, edible fungus technology, applied in application, horticulture, botanical equipment and methods, etc., can solve the problems of poor inoculation quality, manual bagging, time-consuming and labor-intensive, etc. Product quality, the effect of reducing the building area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

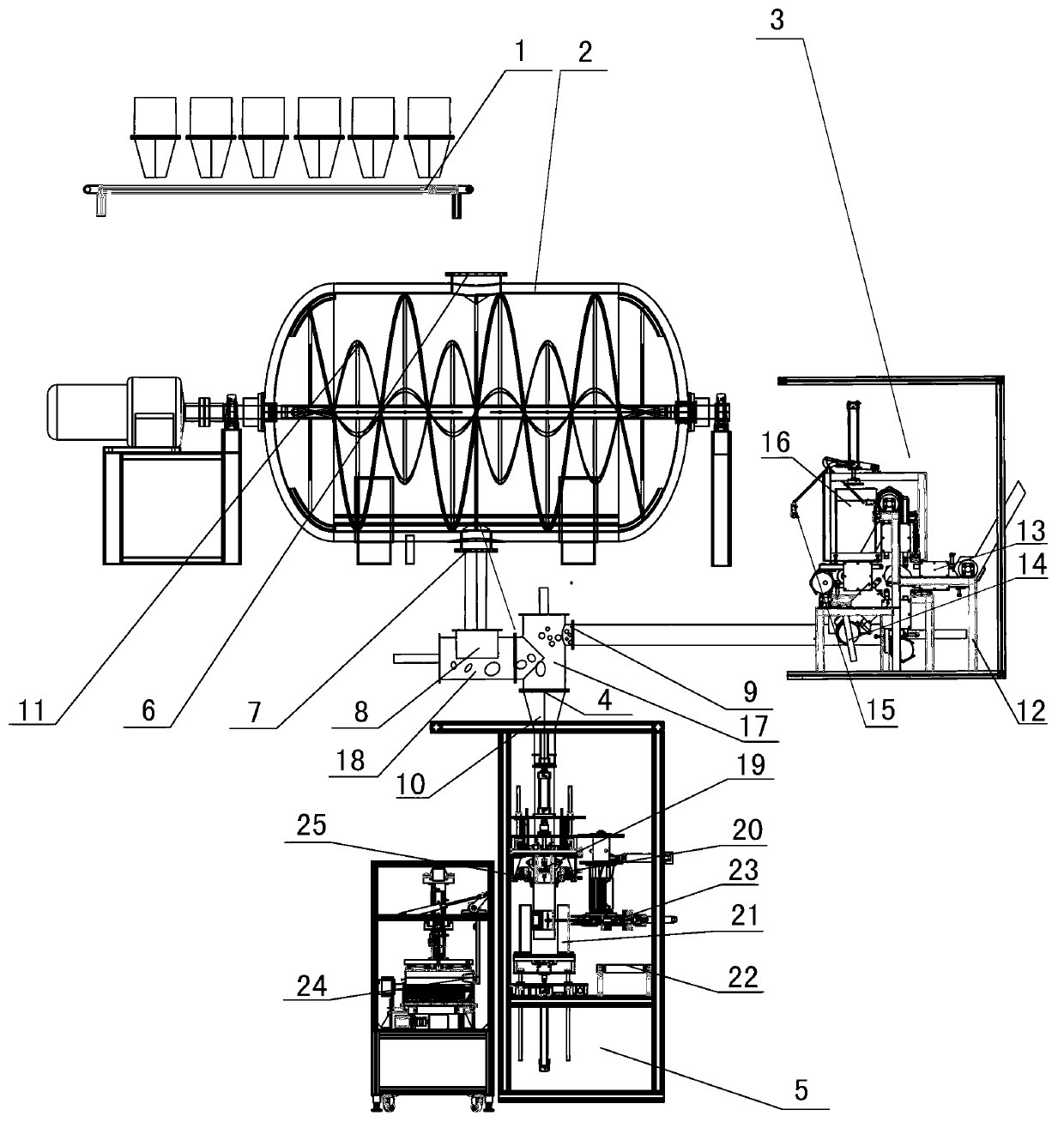

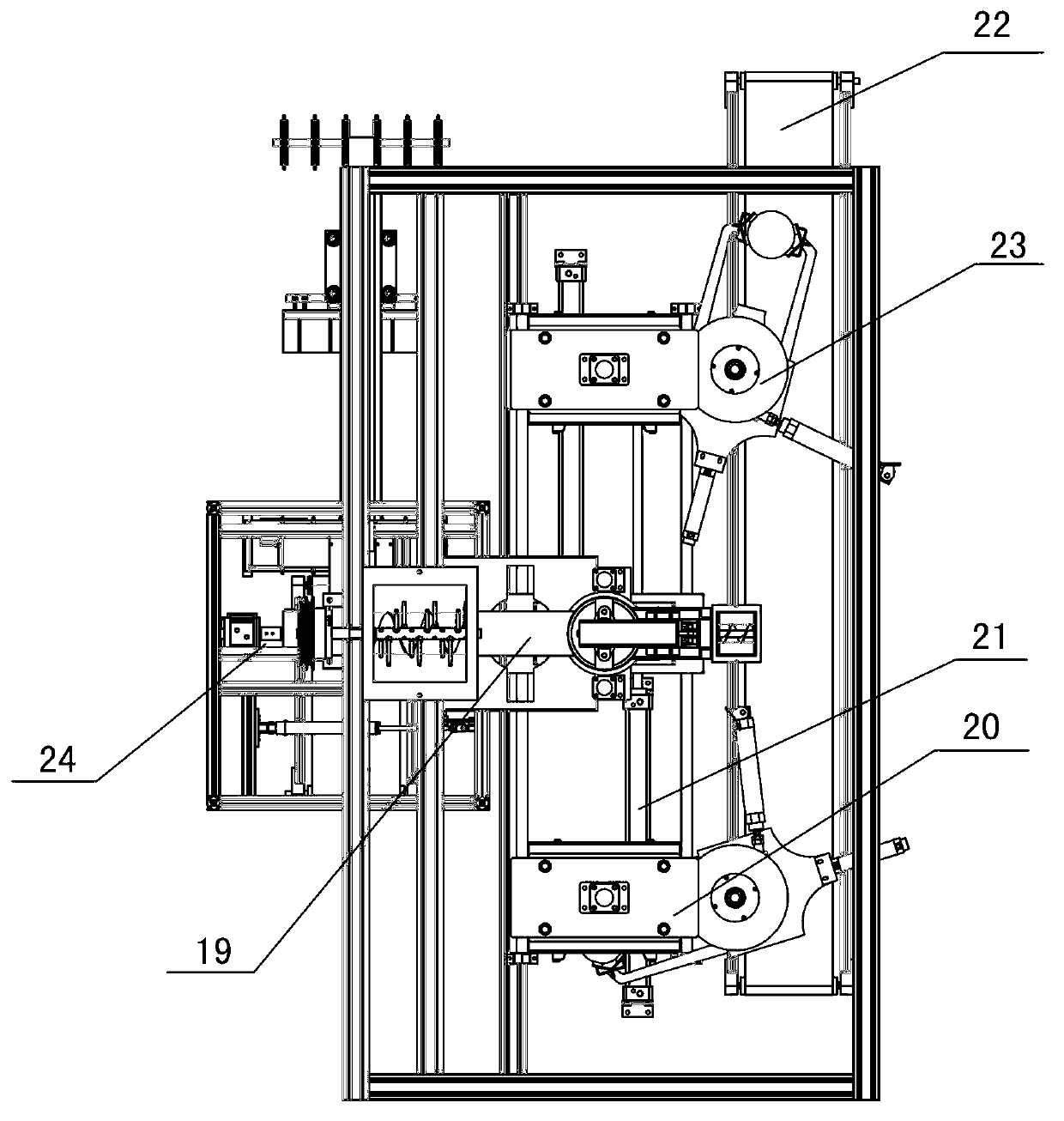

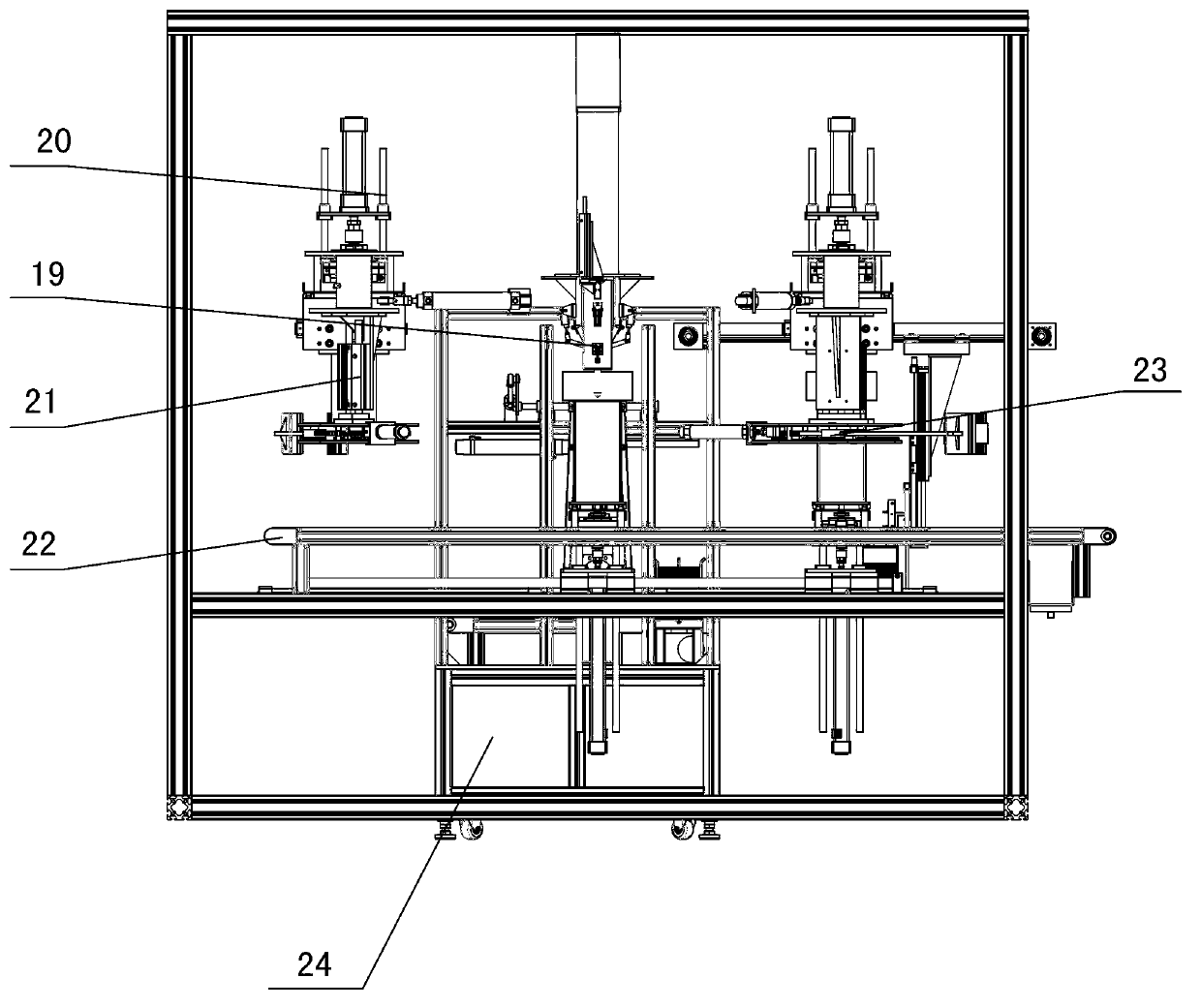

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0017] Such as Figure 1~3 As shown, the edible fungus automatic production line includes an electronic automatic batching and weighing system 1, a sterilizing pot 2, an edible fungus automatic inoculating machine 3, a spiral automatic bagging machine 4 and a bagging conveying mechanism 5. The top of the sterilizing pot 2 is provided with an inlet The feed port assembly 6, the bottom is provided with a discharge port assembly 7, and the spiral automatic bagging machine 4 is provided with a culture medium feed port 8, a strain feed port 9 and a mixing discharge port 10, electronic automatic batching and weighing The discharge port of the system 1 is located above the feed port assembly 6 of the sterilizing pot 2, and the discharge port assembly 7 of the sterilizing pot 2 is connected with the medium feed port 8 of the spiral automatic bagging machine 4, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com