A CVD diamond growth online detection method and system

A detection method and detection system technology, applied in measurement devices, metal material coating processes, instruments, etc., can solve the problems of long diamond cycle, prone to downtime, complicated calculation, etc., achieve uniform growth rate and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

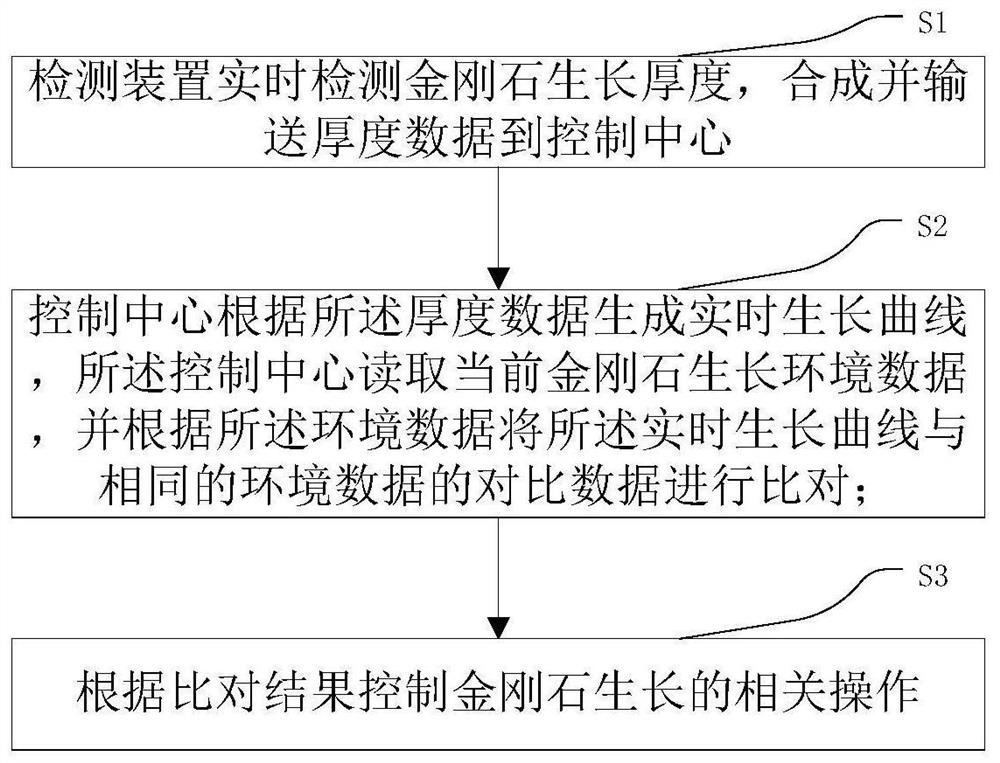

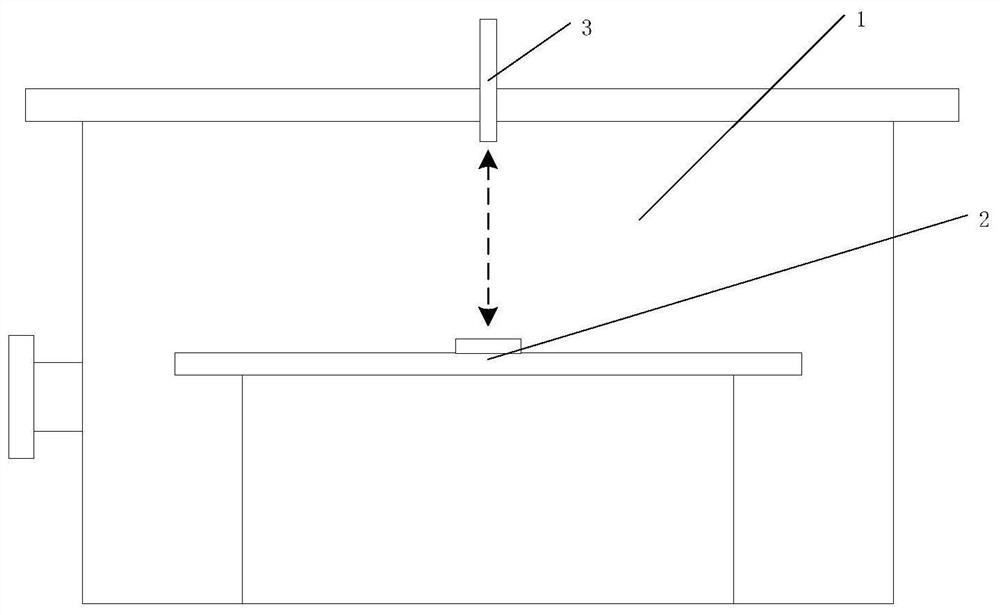

[0042] Please also refer to Figure 1-3 , the present invention provides a kind of CVD diamond growth on-line detection method, comprising steps:

[0043] S1. The detection device 3 detects the diamond growth thickness in real time, generates and transmits the thickness data to the control center 4;

[0044] S2, the control center 4 generates a real-time growth curve according to the thickness data, the control center 4 reads the current diamond growth environment data, and compares the real-time growth curve with the comparison data of the same environment data according to the environment data right;

[0045] S3. Controlling related operations of diamond growth according to the comparison result.

[0046] As a preferred solution, in this embodiment, the detection device is a position sensor; the real-time detection is detection once at predetermined time intervals. Because the diamond has a long growth cycle, and the height of the growth is generally tens of microns or ev...

Embodiment 2

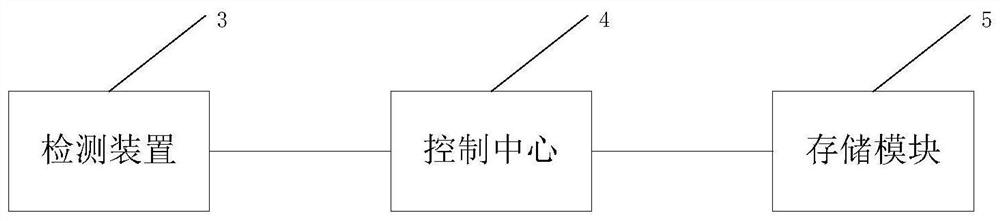

[0069] Please focus on image 3 , the present invention also provides a CVD diamond growth on-line detection system, including a detection device 3, a control center 4, and a storage module 5;

[0070] The detection device 3 is used to detect the surface position of the diamond in real time, generate and output thickness data;

[0071] The storage module 5 is used to store the comparison data and real-time detection data;

[0072] The control center 4 is used to receive the thickness data, read the comparison data in the storage module 5, perform data comparison, and control the operation of the equipment according to the comparison result.

[0073] As a preferred solution, in this embodiment, an alarm device (not shown) is also included; the alarm device includes an LED and a loudspeaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com