Electric kettle

A technology for electric kettles and kettle bodies, which is applied to water boiling appliances, cooking utensils, household appliances, etc. It can solve problems such as potential safety hazards, insufficient strength, heat accumulation and deformation at the bottom, etc., to ensure safety performance, maintain appearance, and maintain aesthetics consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

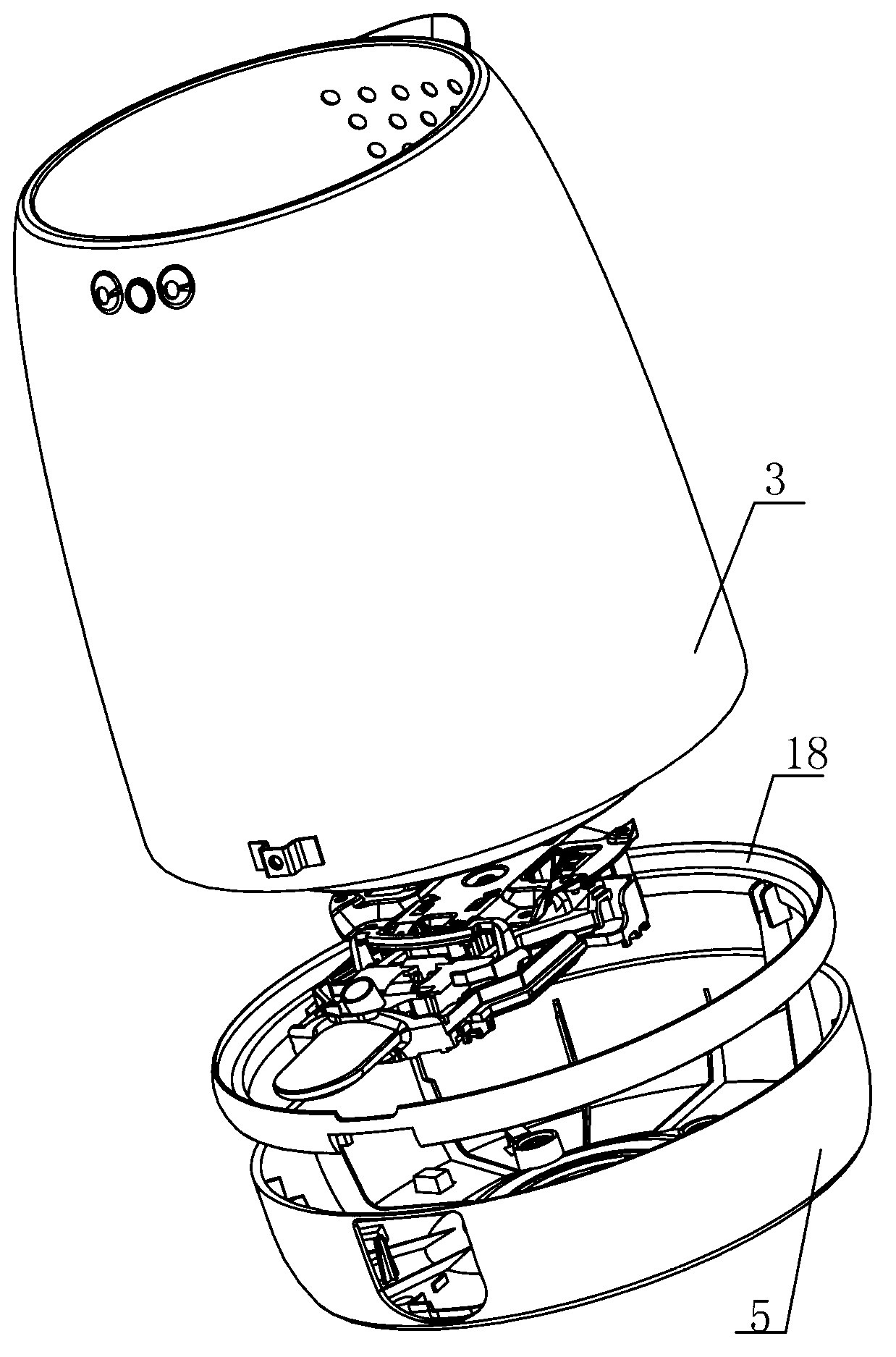

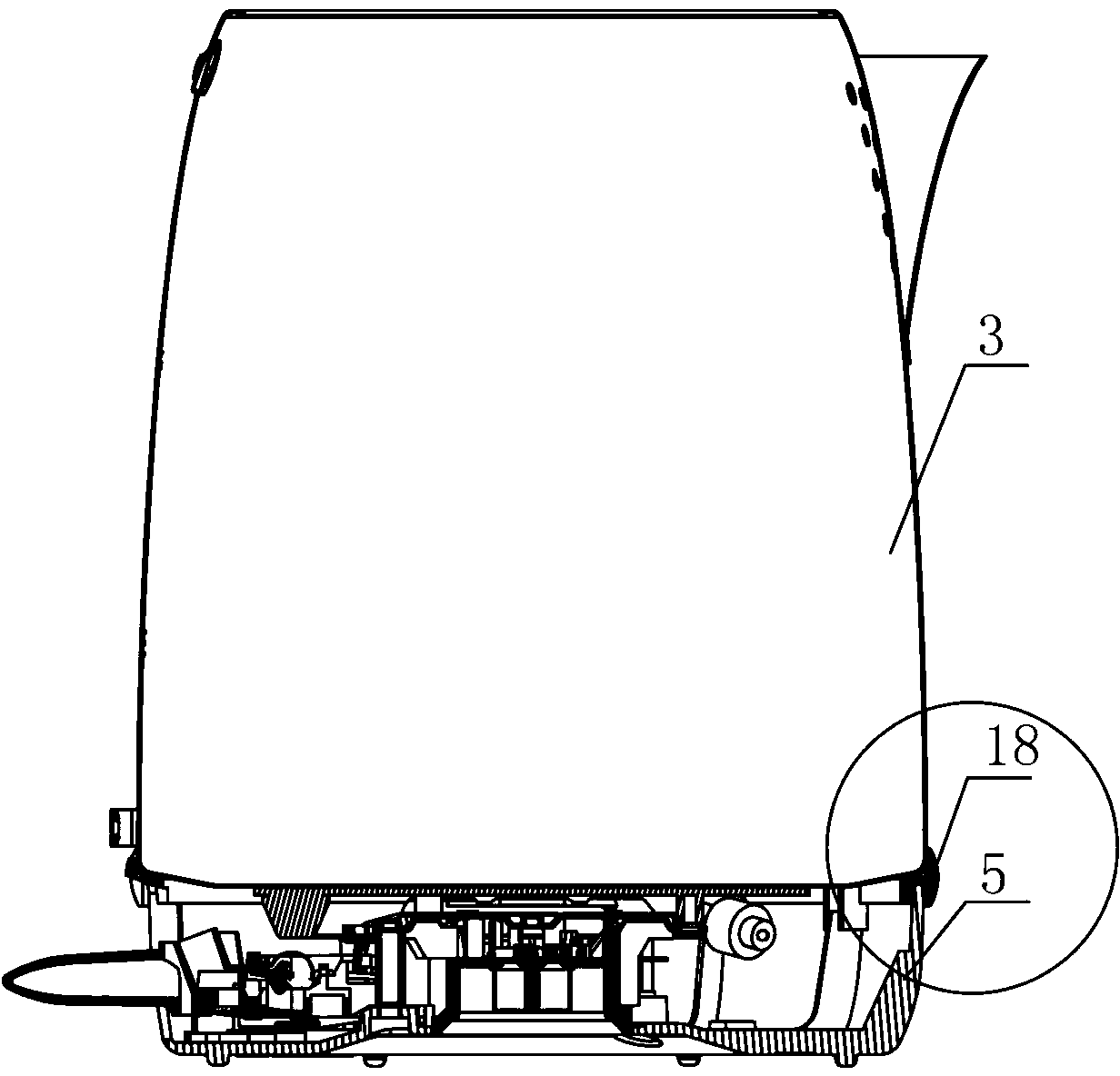

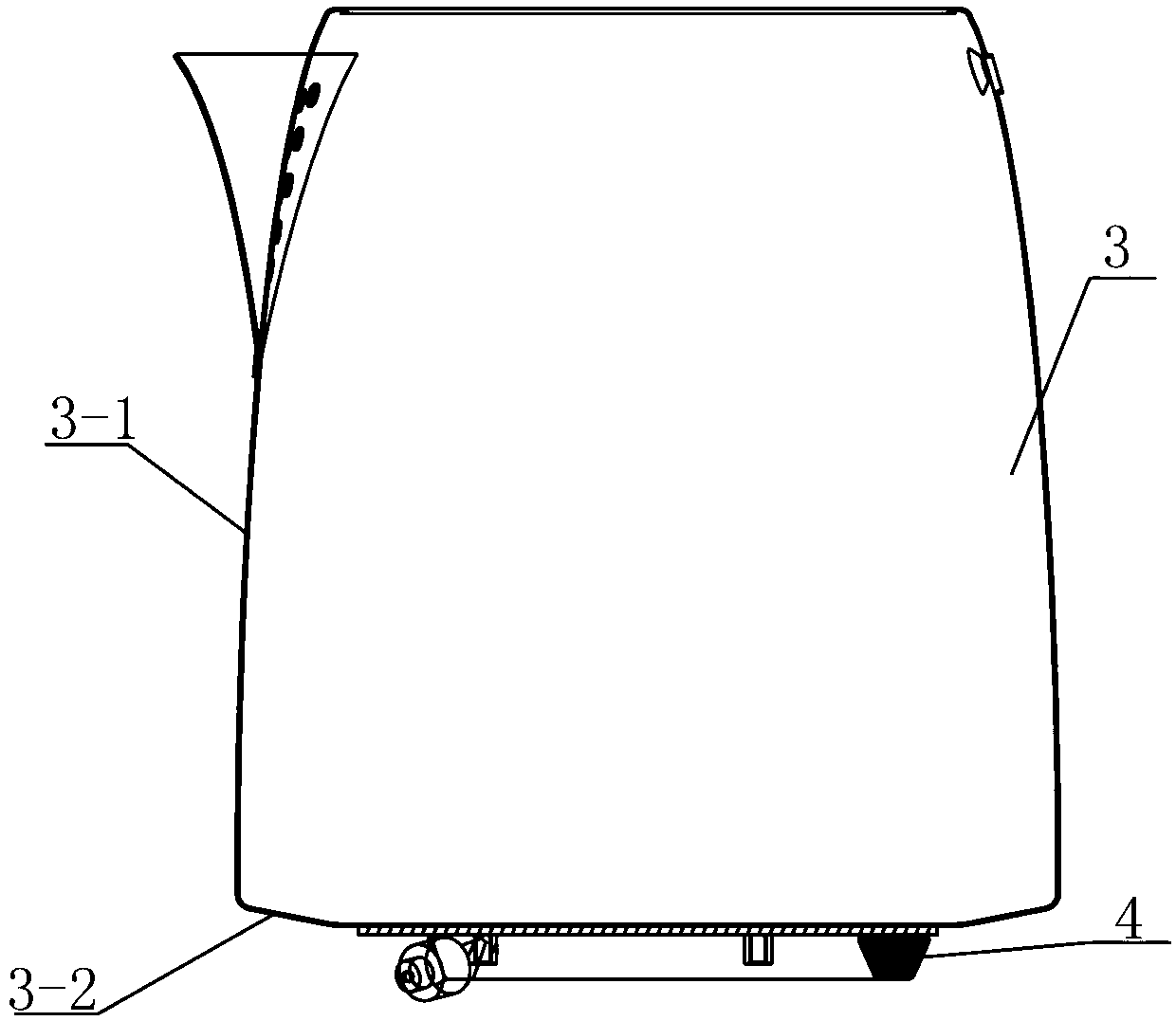

[0027] Embodiment 1, with reference to attached Figure 1-5 .

[0028] The electric kettle of the present invention comprises a kettle main body and a base electrically coupled thereto, the kettle main body includes a handle assembly, a kettle lid assembly, a kettle body assembly 3 including a spout and a liquid containing cavity, and is arranged on the bottom outside the liquid containing cavity The heating component 4 on the top, and the bottom cover component 5 connected with the heating component 4.

[0029] The kettle body assembly 3 includes an upper kettle body 3-1 and a back cover sheet 3-2, and the upper kettle body 3-1 and the back cover sheet 3-2 are seamlessly butt-welded to form the liquid containing chamber of the kettle body assembly 3, and the kettle body Component 3 is made up of the liquid containing cavity and spout that upper body 3-1 and back cover 3-2 form; -1 After the butt welding is completed, there is no visually visible gap in the liquid storage ca...

Embodiment 2

[0038] Embodiment 2, with reference to attached Figure 1-3 6.

[0039] The electric kettle of the present invention comprises a kettle main body and a base electrically coupled thereto, the kettle main body includes a handle assembly, a kettle lid assembly, a kettle body assembly 3 including a spout and a liquid containing cavity, and is arranged on the bottom outside the liquid containing cavity The heating component 4 on the top, and the bottom cover component 5 connected with the heating component 4.

[0040] The kettle body assembly 3 includes an upper kettle body 3-1 and a back cover sheet 3-2, and the upper kettle body 3-1 and the back cover sheet 3-2 are seamlessly butt-welded to form the liquid containing chamber of the kettle body assembly 3, and the kettle body Component 3 is made up of the liquid containing cavity and spout that upper body 3-1 and back cover 3-2 form; -1 After the butt welding is completed, there is no visually visible gap in the liquid storage c...

Embodiment 3

[0049] Embodiment 3, with reference to attached Figure 1-3 , 7.

[0050] The electric kettle of the present invention comprises a kettle main body and a base electrically coupled thereto, the kettle main body includes a handle assembly, a kettle lid assembly, a kettle body assembly 3 including a spout and a liquid containing cavity, and is arranged on the bottom outside the liquid containing cavity The heating component 4 on the top, and the bottom cover component 5 connected with the heating component 4.

[0051] The kettle body assembly 3 includes an upper kettle body 3-1 and a back cover sheet 3-2, and the upper kettle body 3-1 and the back cover sheet 3-2 are seamlessly butt-welded to form the liquid containing chamber of the kettle body assembly 3, and the kettle body Component 3 is made up of the liquid containing cavity and spout that upper body 3-1 and back cover 3-2 form; -1 After the butt welding is completed, there is no visually visible gap in the liquid storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com