Energy-conservation machine tool main shaft drive mechanism and matched lanthanon permanent magnet motor

A rare-earth permanent magnet motor and machine tool spindle technology, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as large reverse starting current, easily damaged components, and energy-consuming system impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

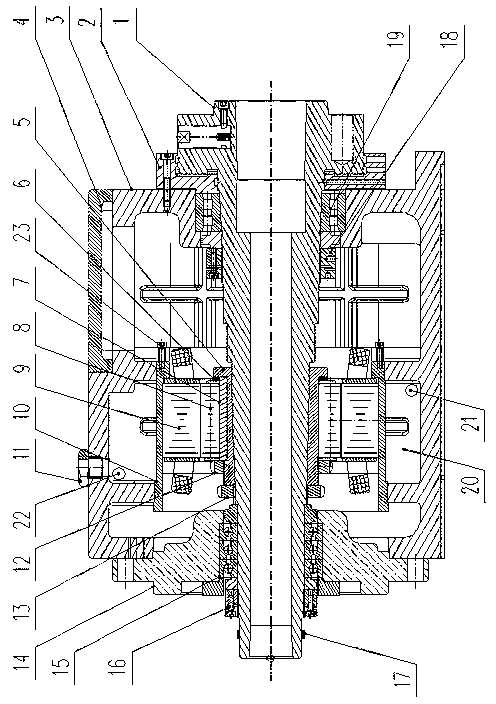

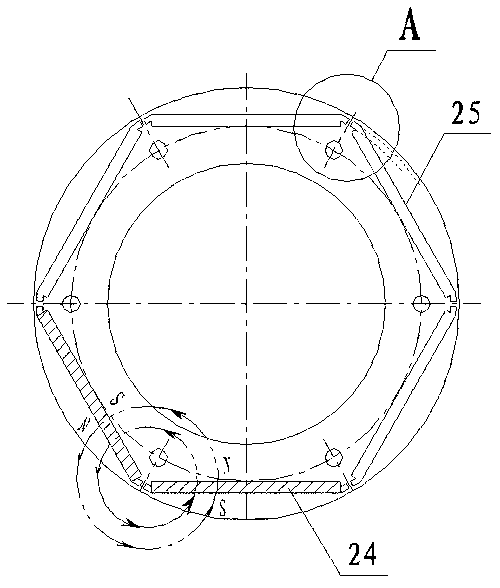

[0022] Novel machine tool spindle drive mechanism of the present invention, as figure 1 As shown, it includes a spindle box 3 and a permanent magnet motor built in the spindle box 3 and a machine tool spindle 1. The permanent magnet motor includes a motor stator 9 and a motor rotor 8 for driving the machine tool spindle 1 to run. The permanent magnet motor The motor casing 10 is supported and connected by two supporting rings arranged on the inner wall of the spindle box 3, so as to form a sealed cooling fluid circulation between the outer wall of the motor casing 10, the inner wall of the spindle box 3 and the two supporting rings Cavity 20.

[0023] The above-mentioned headstock 3 is respectively provided with a cooling fluid inlet 21 and a cooling fluid outlet 22 connected with the flow cavity 20 on the side wall between the two support rings, so as to inject and To discharge the cooling fluid, a cooling fluid temperature measuring probe fixing base 11 is provided on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com