Material distribution device for magnesite electric smelting furnace

A technology of electric fused magnesium furnace and material distributing device, which is applied in the direction of furnace materials, furnaces, crucible furnaces, etc., can solve the problems of great safety hazards, threats to the health of operators, and difficulty in ensuring the uniformity of material distribution, so as to reduce labor intensity and install Easy dismantling and maintenance, and the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

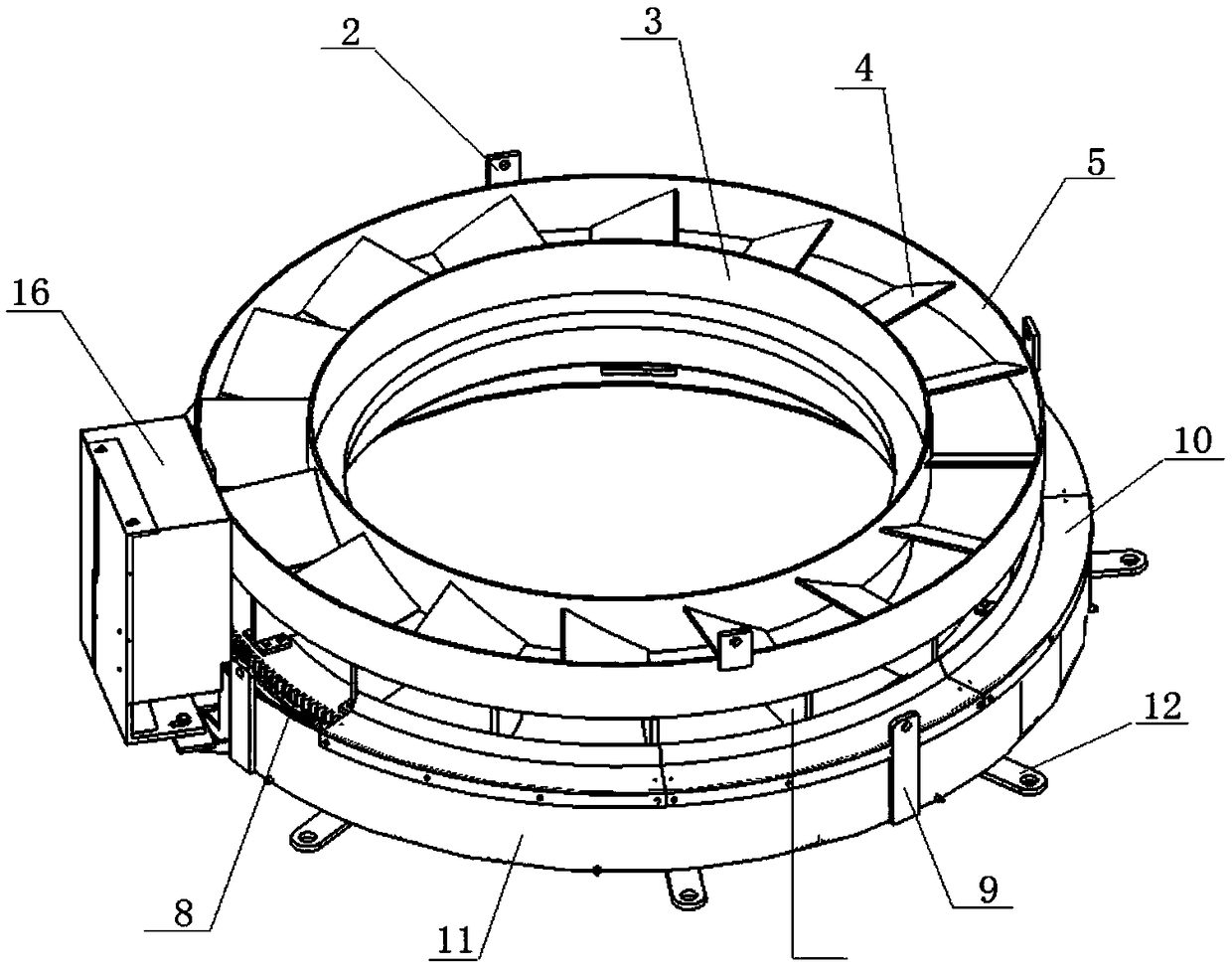

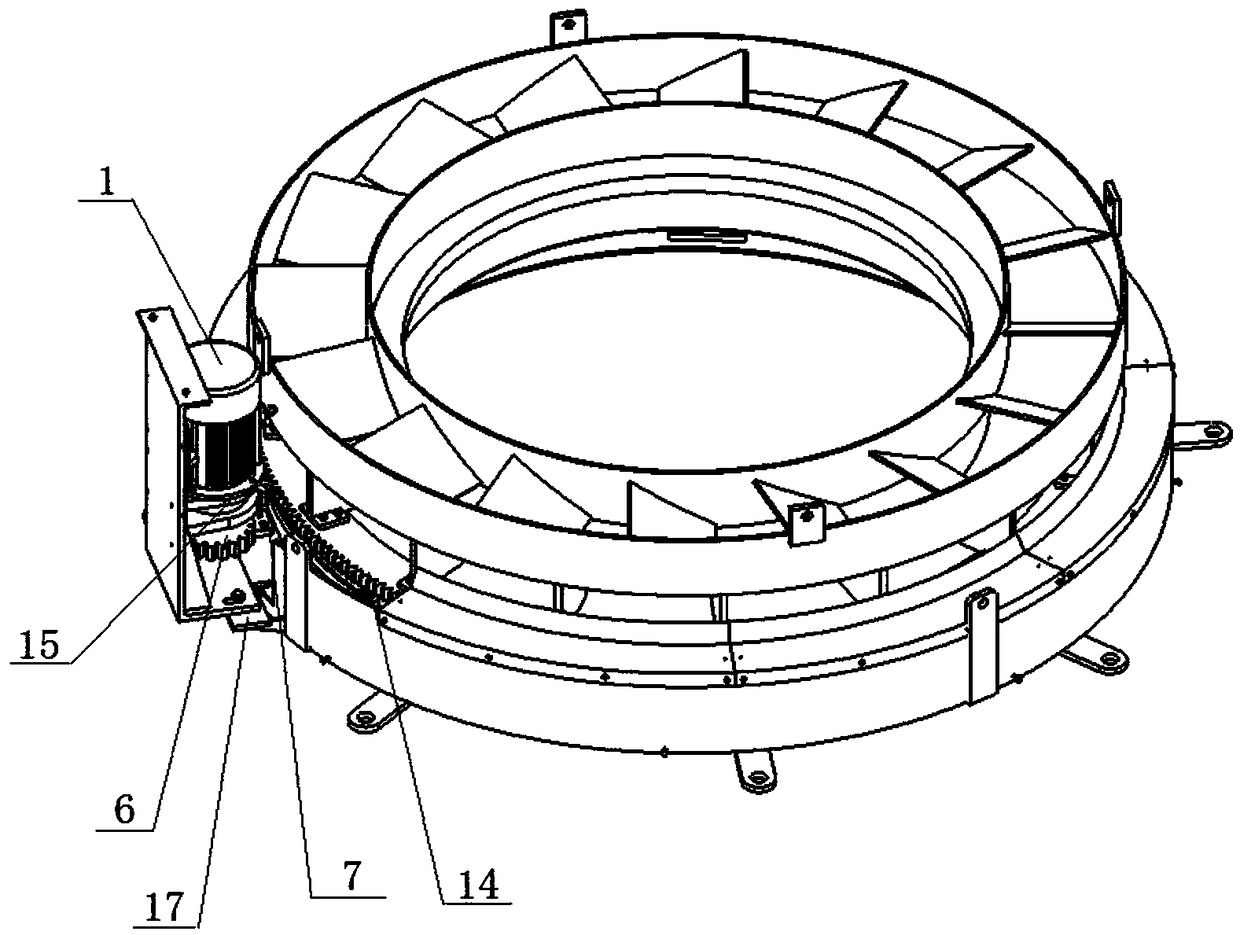

[0025] like figure 1 , figure 2 As shown, a material distribution device for an electric fused magnesium furnace according to the present invention is arranged above the furnace mouth of the electric fused magnesium furnace; it includes a fixed assembly, a rotating assembly, a motor 1 and a transmission device; the fixed assembly consists of a bottom ring 11 and cover body 10, wherein the bottom ring 11 is fixedly connected with the furnace mouth of the fused magnesium furnace; A plurality of support wheels 14 are supported on the bottom ring 11, the outer ring 5 is fixed on the inner side of the bottom ring 11, and the outer ring 5 is connected with the inner ring 3 through a plurality of fan blades 4; the motor 1 drives the ring gear 8 on the bottom ring through a transmission device. 11, the rotating distribution mechanism consisting of oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com