Motorbike economizer with spiral springs

A technology of coil springs and motorcycles, applied in the field of motorcycle energy savers, can solve the problems of high pressure on energy savers, difficulty in mass production, and difficulty in processing and molding, so as to improve engine life, reduce quality control costs, and improve processing quality. Very Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

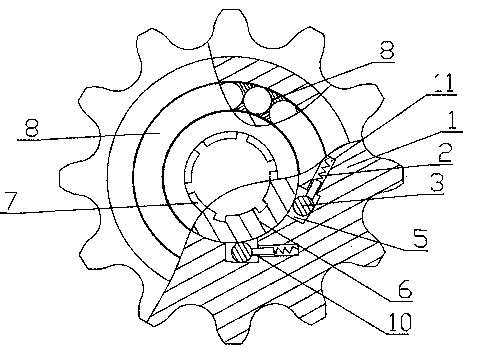

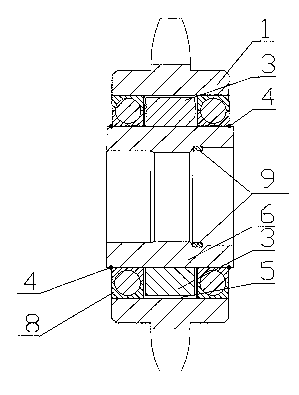

[0019] Specific examples of the present invention are attached figure 1 , 2 , 3, it is composed of wheel body 1, inner sleeve 6, roller 3, bearing 8, inner circlip 9; the inner ring of wheel body 1 is provided with wedge groove 5, and the middle of wheel body 1 is equipped with inner sleeve 6. The inner hole of the inner sleeve 6 is processed with a spline 7 and a groove for installing the inner circlip 9; it is characterized in that a spring groove 1 is processed in the wedge groove 5, and a spring 2 is installed in the spring groove 10 ; The outside of the spring 2 is covered with a spring sleeve 4; the spring sleeve 4 is a sleeve with one end closed, and the closed end is in contact with the roller 3. Eight oblique wedge grooves 5 can be provided. Roller 3 is housed in each wedge groove 5; Bearing 8 is equipped with symmetrically on both sides between wheel body 1 and inner cover 6, and bearing 8 is painted on the outer surface when assembling 2 and sticks to the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com