Glass substrate production method

A technology for glass substrates and manufacturing methods, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve problems such as uneven display, liquid crystal cell gap error, etc., and achieve the effect of suppressing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

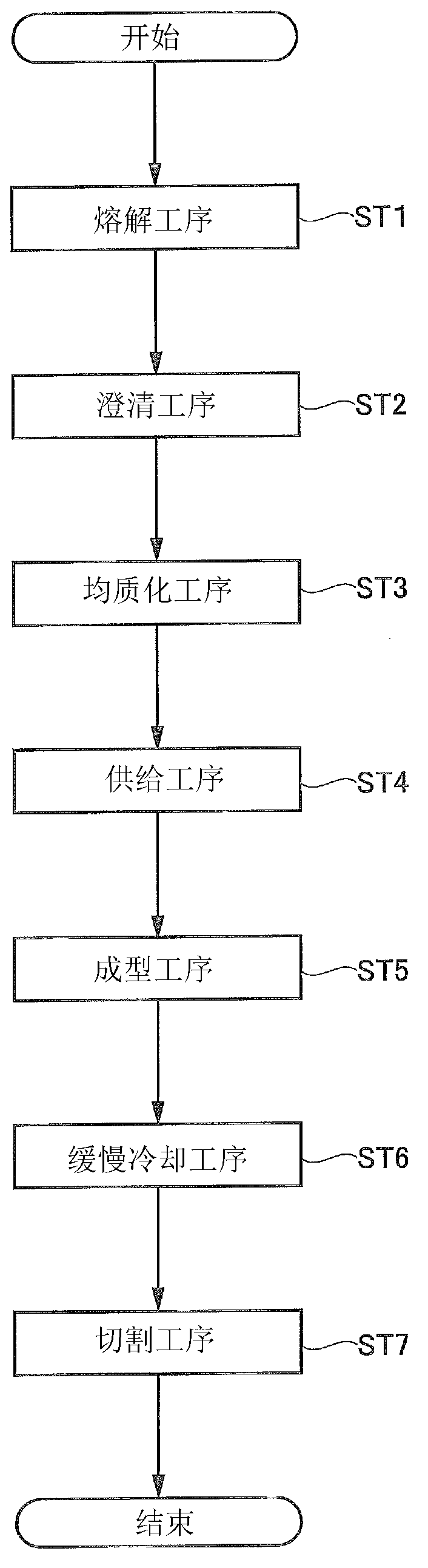

[0029] Hereinafter, the manufacturing method of the glass substrate of this embodiment is demonstrated. figure 1 It is a figure which shows an example of the process of the manufacturing method of the glass substrate of this invention.

[0030] (Overall Outline of Manufacturing Method of Glass Substrate)

[0031] The manufacturing method of a glass substrate mainly includes a melting process (ST1), a clarification process (ST2), a homogenization process (ST3), a supply process (ST4), a molding process (ST5), a slow cooling process (ST6), and a cutting process ( ST7). In addition, there are also a grinding process, a grinding process, a cleaning process, an inspection process, a packaging process, etc., and a worker who transports two or more glass substrates stacked in the packaging process to the ordering party.

[0032] The melting process (ST1) is performed in a melting tank. In the melting step, the molten glass in which the temperature of the surface layer including t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com