Integrated machine room

A machine room and column technology, which is applied to special buildings, small buildings, building components, etc., can solve the problems of on-site geographical environment restrictions, inconvenient transportation, etc., and achieve the effect of reducing transportation difficulty, shortening construction period, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

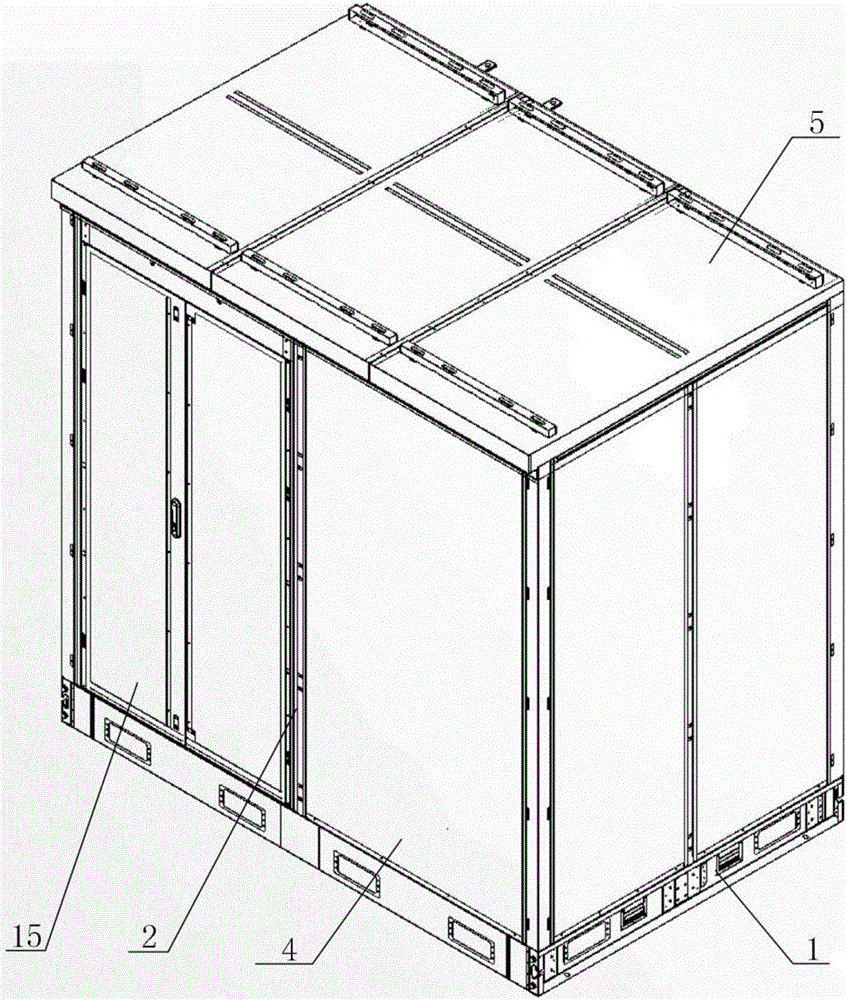

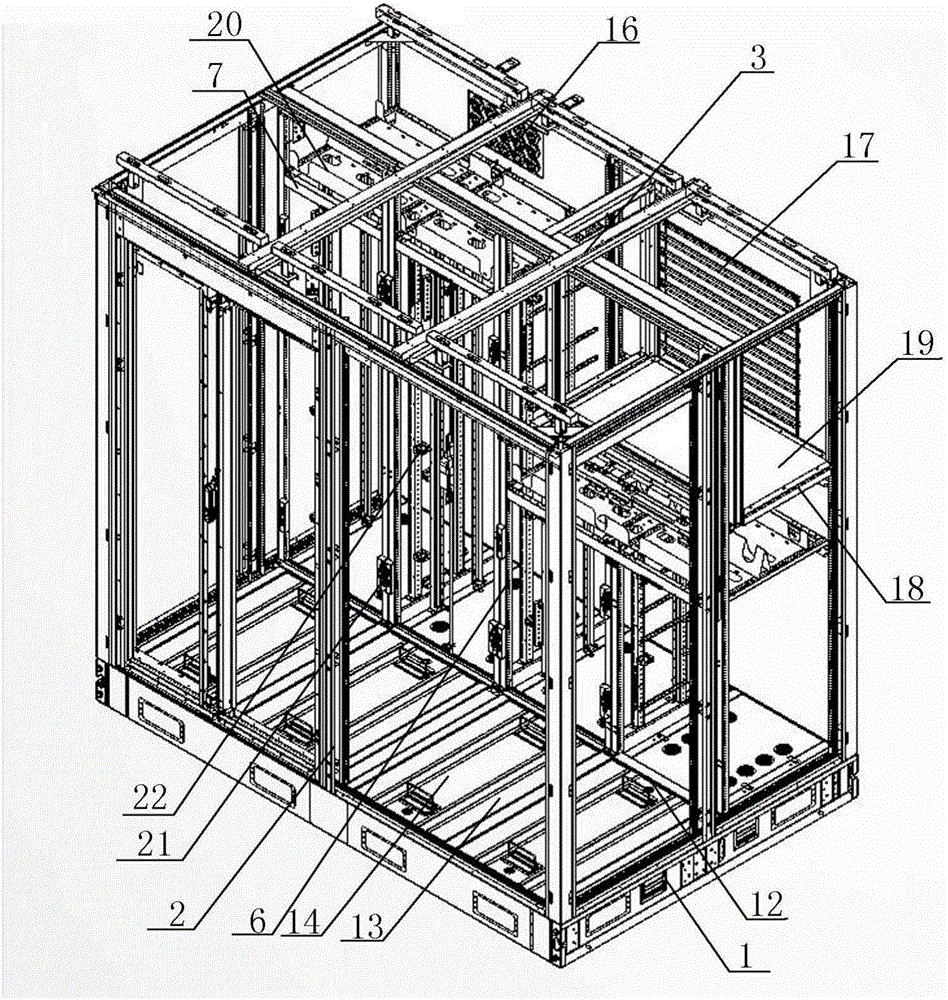

[0037] An integrated machine room, comprising a base 1, a plurality of external columns A2 are arranged on the base 1, a top frame 3 is connected to the upper end of the external column A2, a wall panel 4 is installed between adjacent external columns A2, and a top frame 3 is provided There is a top cover 5, and a plurality of internal columns B6 are arranged on the base 1, and installation frames 7 for dividing the machine room into each cabin are arranged between the internal columns B6. The frame 3, the external column A2 and the wall panel 4, the top frame 3 and the top cover 5, the base 1 and the internal column B6 are all detachably connected.

Embodiment 2

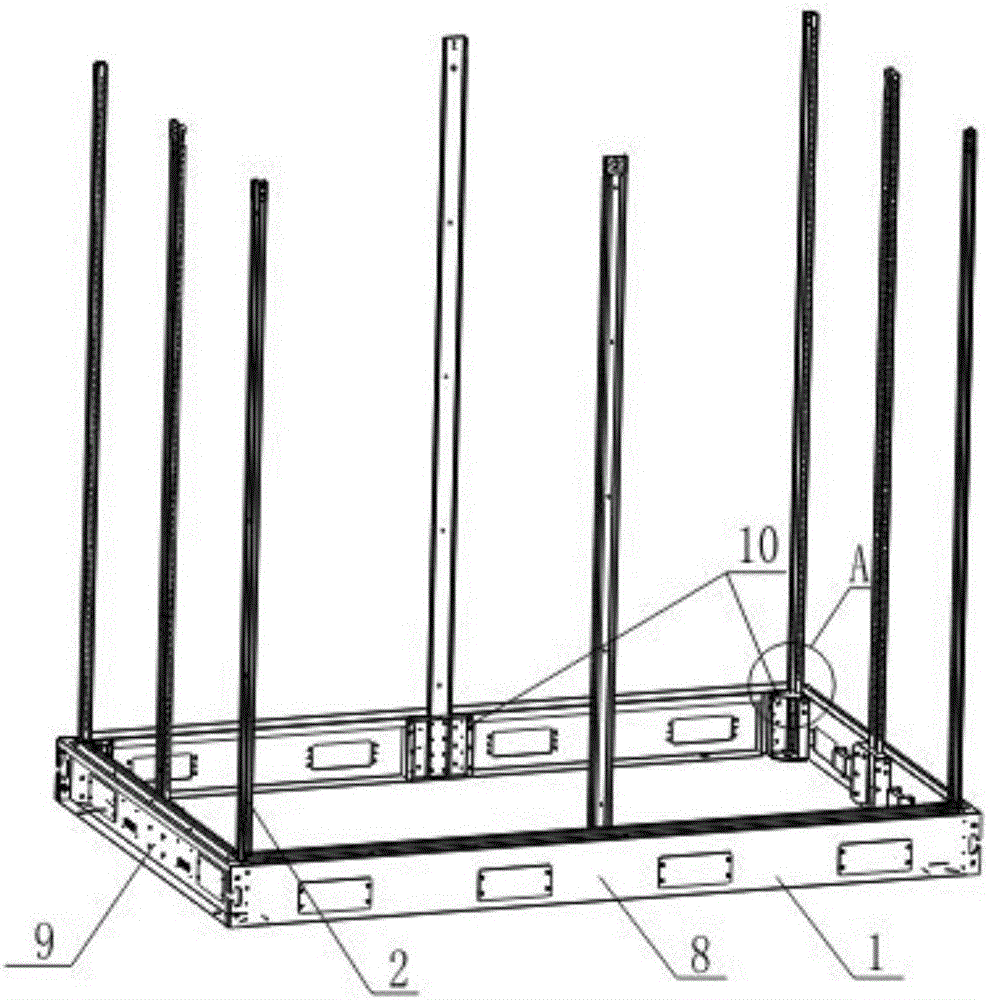

[0039] In this embodiment, on the basis of Embodiment 1, the base 1 includes a long frame 8 and a short frame 9, and the long frame 8 and the short frame 9 form a frame structure through screw connections, and the long frame 8 and the short frame The frame 9 and the four frame corners of the base 1 are screwed with connectors 10, and the connectors 10 are provided with slots 11 for the external column A2 to pass through.

Embodiment 3

[0041] In this embodiment, on the basis of Embodiment 2, the short frames 9 on both sides are connected with an intermediate crossbeam 12 through screw threads, and the intermediate crossbeam 12 and the long frame 8 are connected with multiple rear beams 13 through threads, and the intermediate crossbeam 12 The channel formed with the rear beam 13 is provided with a bottom plate A14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com