I-shaped integrated material for structure and manufacturing method thereof

A manufacturing method and technology of glulam, applied in the direction of manufacturing tools, truss structures, wood processing appliances, etc., can solve the problems of easy opening of glue between product layers, low strength and rigidity, and unoptimized application of component structure and material consumption, etc. To achieve the effect of improving the utilization rate of wood, improving the structural performance, and improving the stability of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

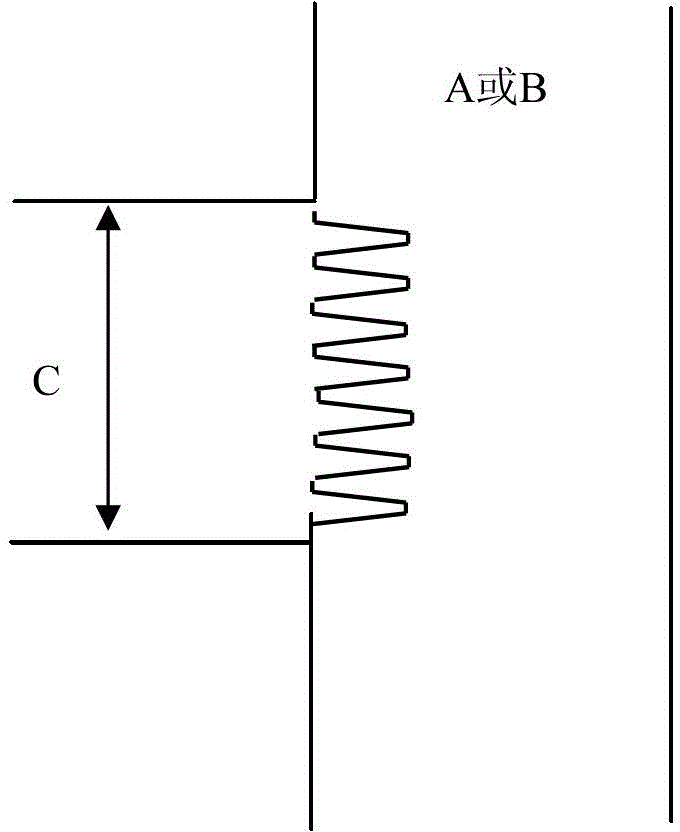

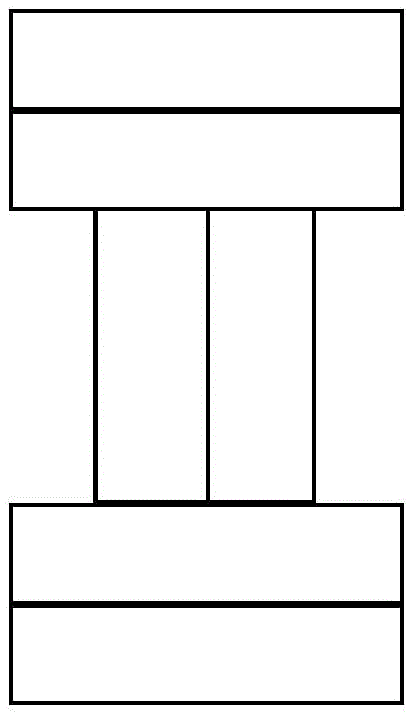

[0037] Prepare the I-shaped laminated material for the structure of this embodiment according to the following steps:

[0038] 1. Sawn timber classification

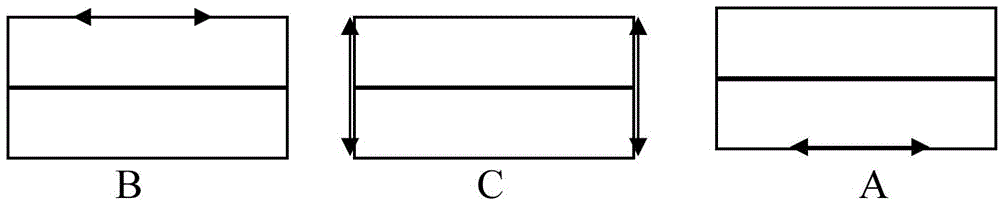

[0039] Choose 30mm thick, 100mm wide and 2000mm long Japanese larch sawn timber. According to the strength probability distribution curve of Japanese larch sawn timber, the elastic modulus is divided into three regions: 8-10GPa, 10-12GPa, and 12-14GPa. 8-10GPa is classified as E1 grade, and 10-12GPa is classified as E2 grade. ~14GPa is classified as E3 grade. Different strengths will be used in different positions of I-shaped laminated timber.

[0040] 2. The manufacturing process of the upper flange glulam

[0041] Choose E2 grade 4 sawn timber, 2 milling teeth at both ends, 2 single-end milling teeth, no shoulder is required. The tooth length is 15mm, the tooth tip width is 0.8mm, and the slope is 1 / 10. Use structural glue resorcinol-formaldehyde or water-based polymer isocyanate resin glue for single-sided painting, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com