Gantry crane travelling unit device

A technology for running parts and gantry cranes, which is applied in the directions of running mechanisms, transportation and packaging, load hanging components, etc. The effect of reliable parking, compact structure and safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

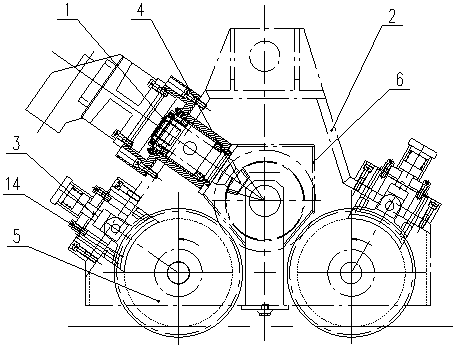

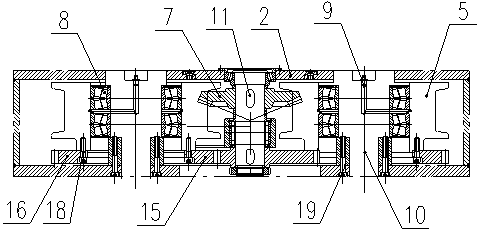

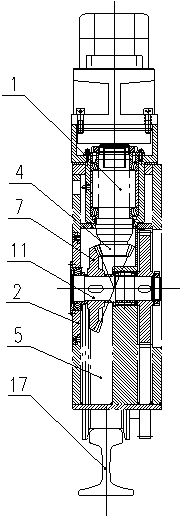

[0021] figure 1 Among them, the motor 1 and the brake cylinder 3 are installed on the outside of the box 2. The motor 1 directly drives the traveling wheel 5, and the transmission gears are arranged in a triangle, and are braked by the hydraulic cylinder 3. The small bevel gear 4 is connected to the output end of the motor 1 and meshes with the large bevel gear. The small bevel gear 4 and the large bevel gear form the high-speed stage of the whole running section. Small bevel gear 4 and big bevel gear outside have lubricating oil tank 6, the thin oil for bevel gear lubrication is housed inside. The power output end of the brake cylinder 3 is connected with the brake shoe 14 . The brake shoe 14 is on the upper side of the rim surface of the running wheel 5, and has a certain distance from the rim surface. When the brake cylinder 3 moves, the brake shoe 14 is pressed on the running wheel 5 to brake the running wheel. The effect of wheel 14 realizes the braking function of ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com