Band saw blade continuous high frequency quenching transmission device

A technology of high-frequency quenching and transmission device, which is applied in the direction of quenching device, transportation and packaging, coiling strips, etc., can solve the problems of unstable transmission of the transmission device, small transmission force, affecting the uniformity and quality of band saw blade quenching, etc. To achieve the effect of stable transmission, large transmission strength and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

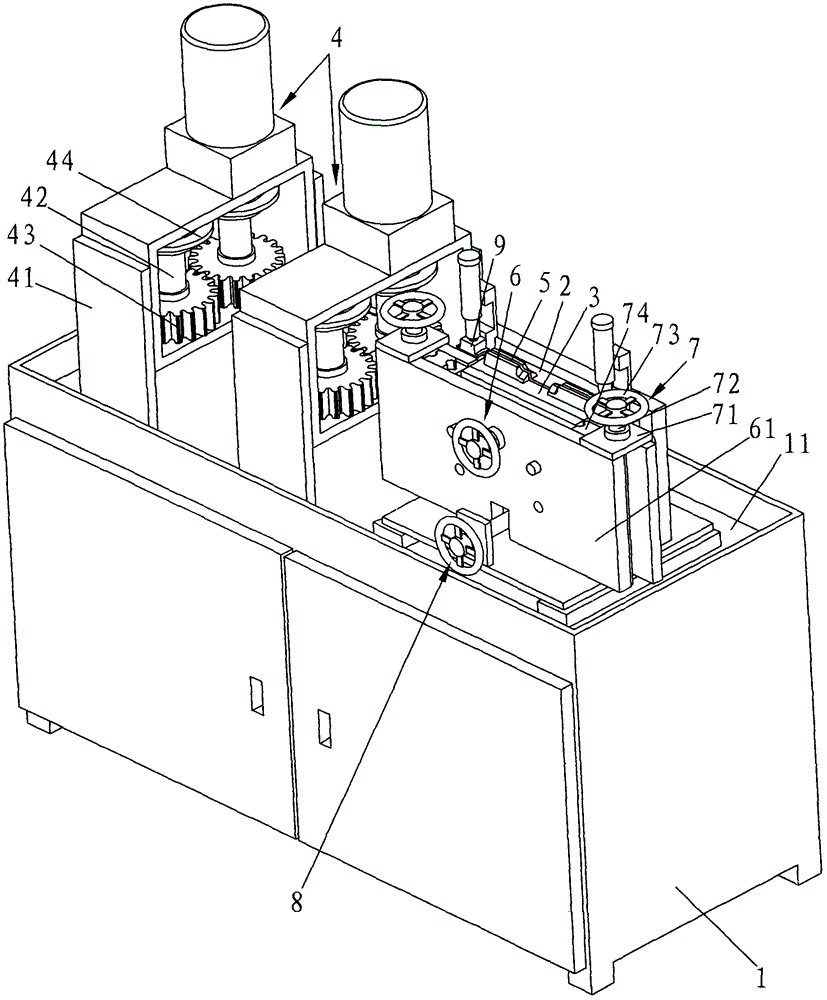

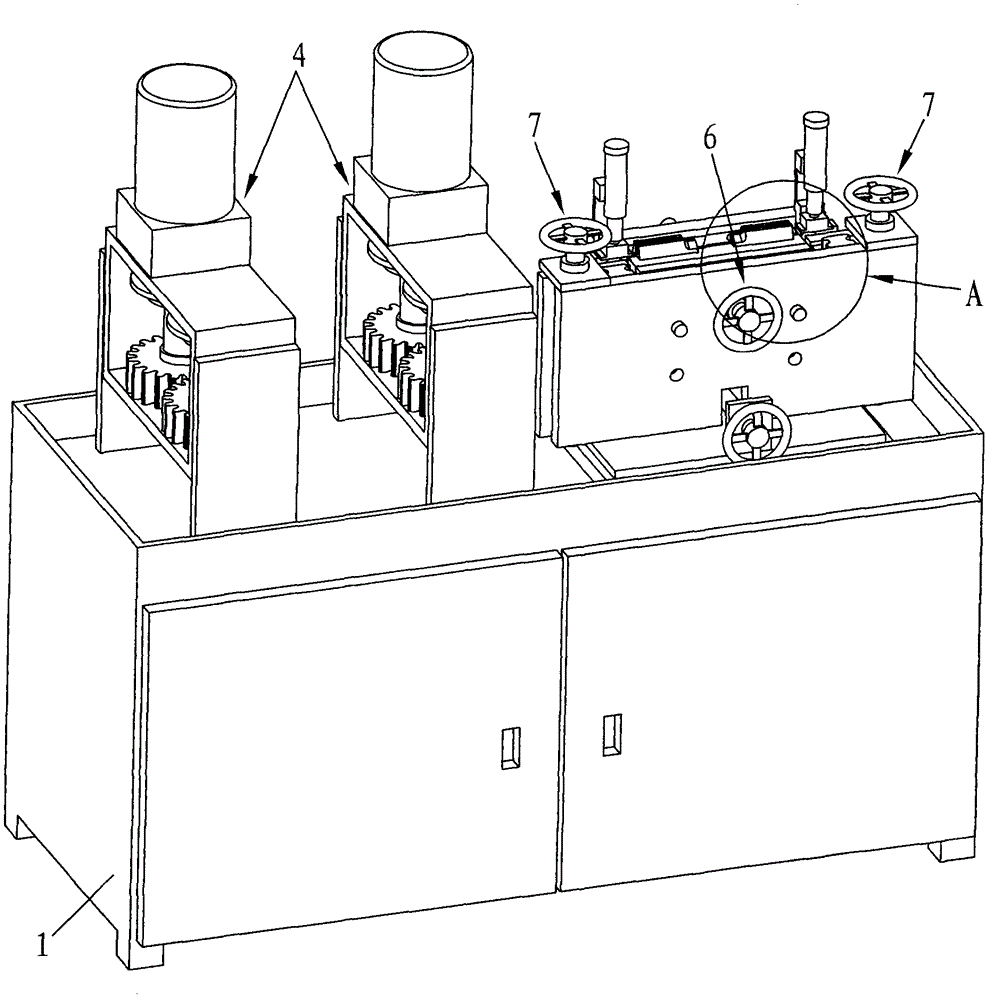

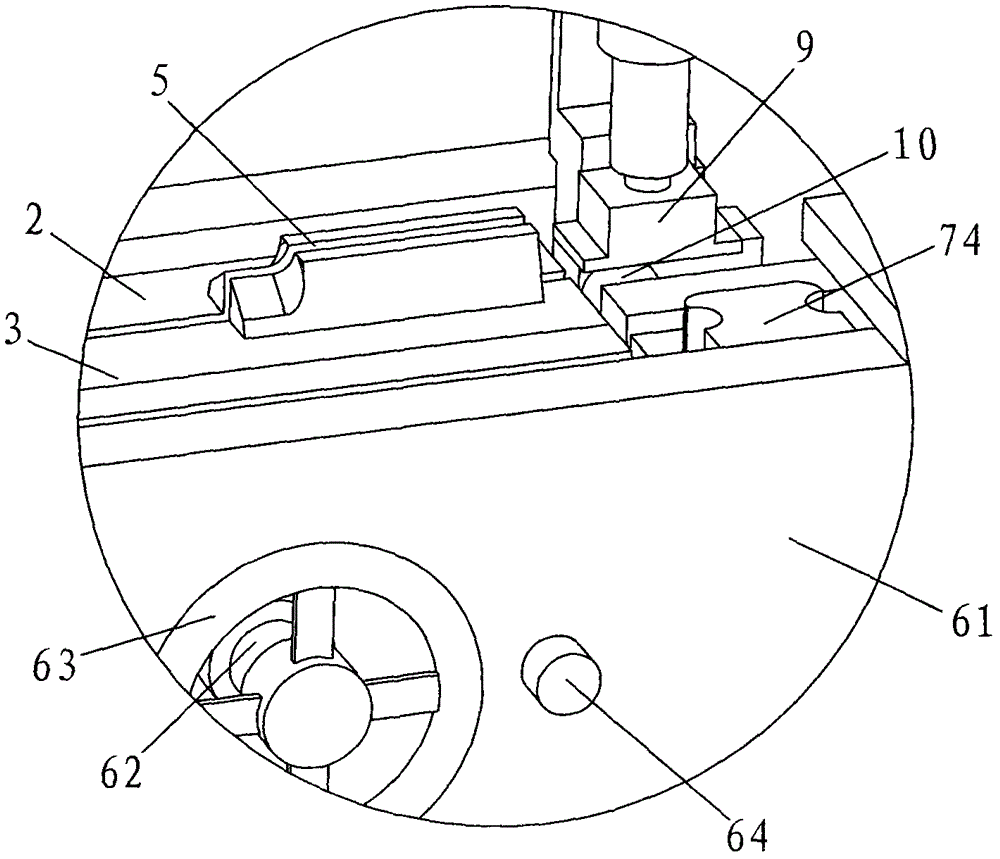

[0011] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~4 As shown, the band saw blade continuous high-frequency quenching transmission device of the present invention includes a frame 1, and the top of the frame 1 is provided with a receiving tank 11, and the receiving tank 11 is provided with a fixed splint 2, a movable splint 3, a traction device 4, and a fixed splint 2 and the movable splint 3 form a clamping groove 5 for the band saw blade to pass through, and the traction device 4 is correspondingly arranged on the exit direction of the clamping groove 5. The traction device 4 includes a bracket 41 fixed on the frame 1, vertically arranged on the Two rotating shafts 42 on the bracket 41, two transmission gears 43 meshing with each other, two traction pressure wheels 44 that cooperate to compress the band saw blade, and a motor 45 that drives and connects the rotating shafts 42, and the two transmission gears 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com