Silicon-based V-shaped groove preparation method with functions of convergence and polarization selection

A V-groove, silicon-based technology, applied in the field of data communication and active optical cable, can solve the problems of indistinguishable signal value, pulse broadening, etc., and achieve the effect of reducing loss and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

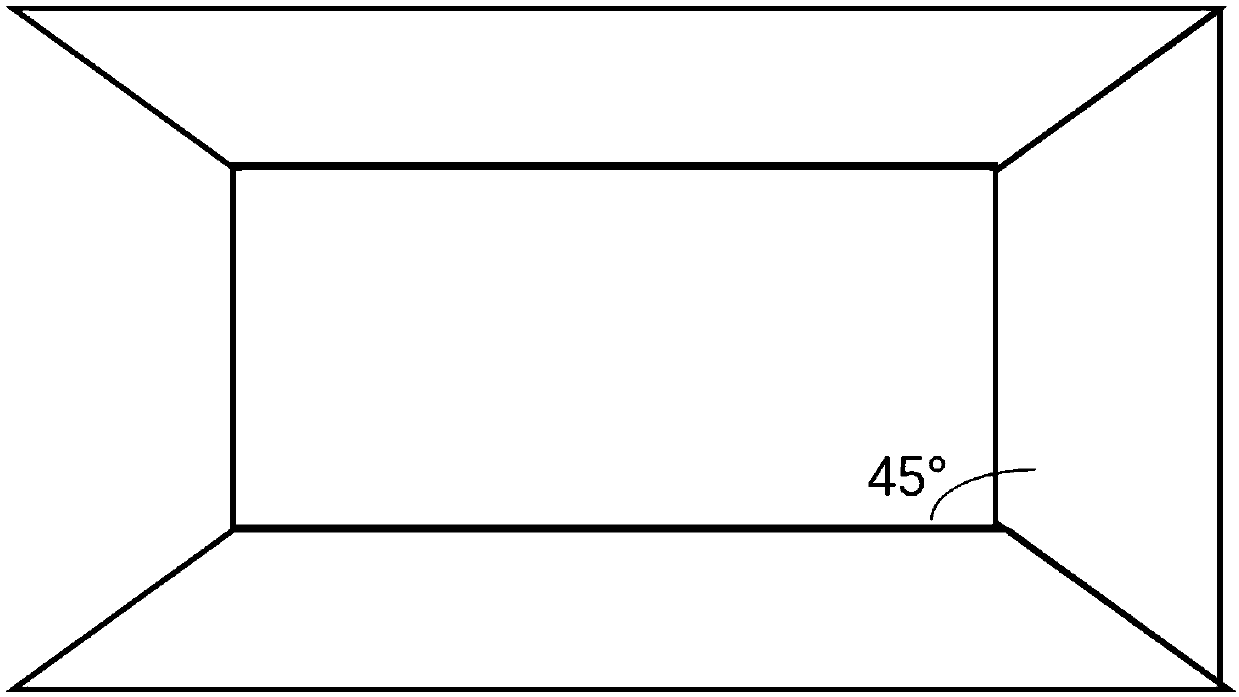

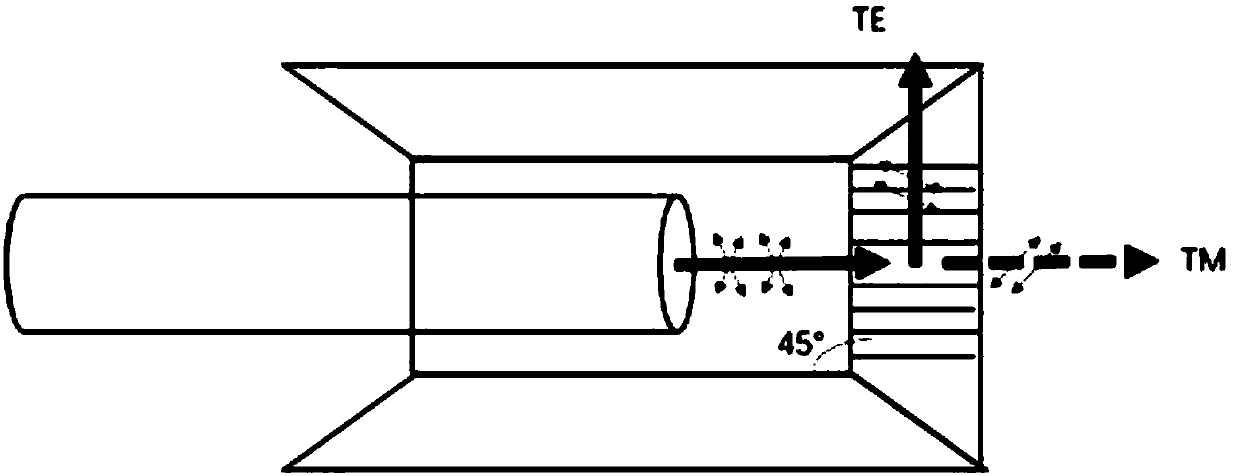

[0021] Such as figure 1 Shown is a schematic structural view of a silicon-based V-groove prepared using the method provided by the present invention. The specific steps for making a silicon-based V-groove are as follows: first, select a silicon wafer, perform acetone, ethanol-ultrasonic cleaning on the selected silicon wafer, rinse with deionized water, and blow dry with nitrogen; then move the treated silicon wafer into a thermal oxidation furnace for further processing. Wet oxygen oxidation, after the oxidation is completed, move it into a thermal annealing furnace for thermal annealing; the second is to perform photolithography and development; the fourth is to use nitrogen to dry it, and then immerse it in HF aqueous solution to prepare SiO 2 Mask; finally, immerse the above-treated silicon wafer in KOH aqueous solution for wet silicon etching to prepare a silicon-based V-groove with a 45° micro-mirror. The ratio of KOH aqueous solution used is KOH:IPA:H 2 O=2:1:10.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com