Hot-winding machine for flange workblank

A blank and flange technology, applied in the field of professional equipment for making flanges, can solve problems such as insufficient utilization of raw materials, inability to eliminate straight line segments, and increase in waste material heads, achieving high success rate, reduced processing costs, and good flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

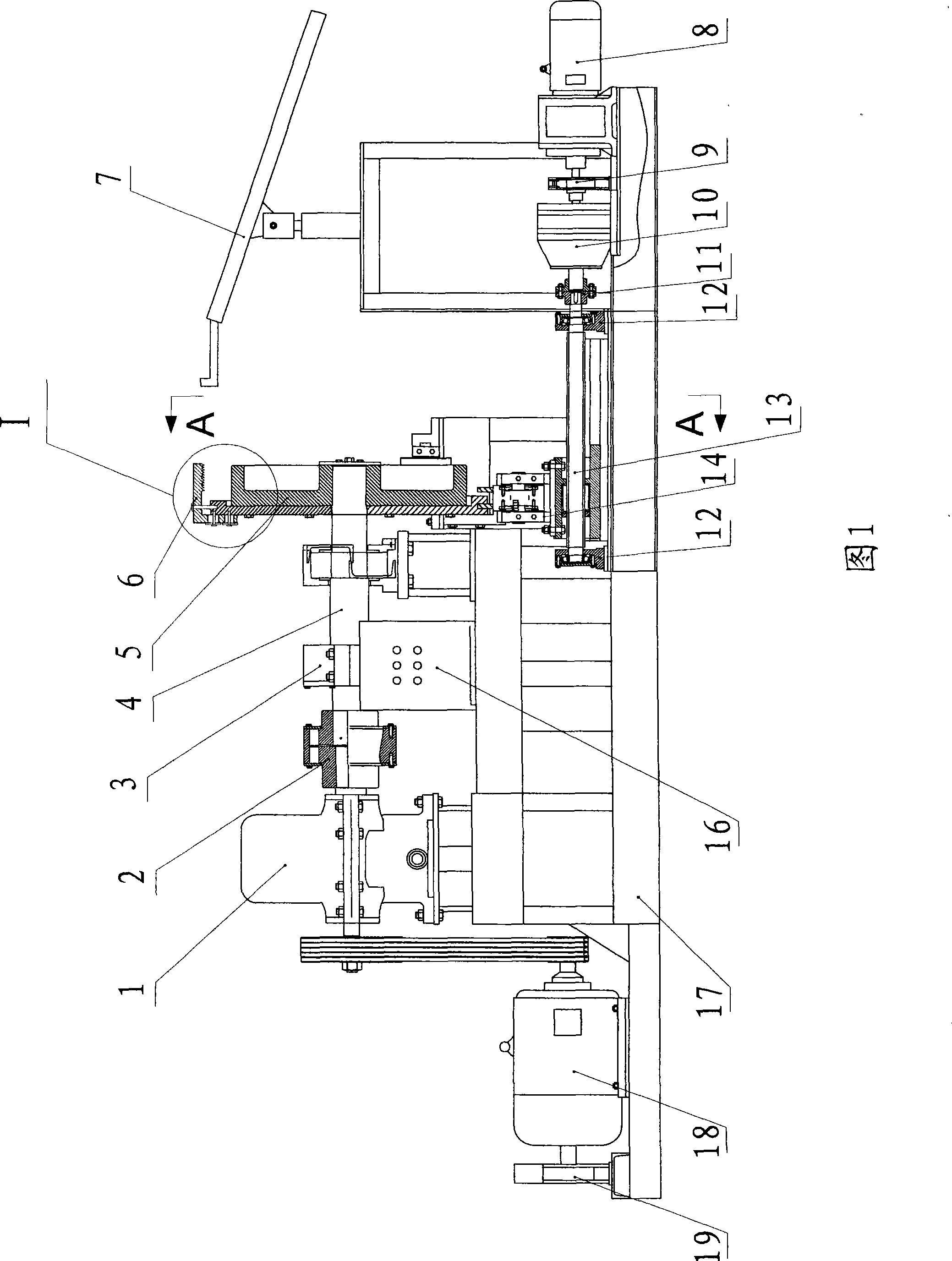

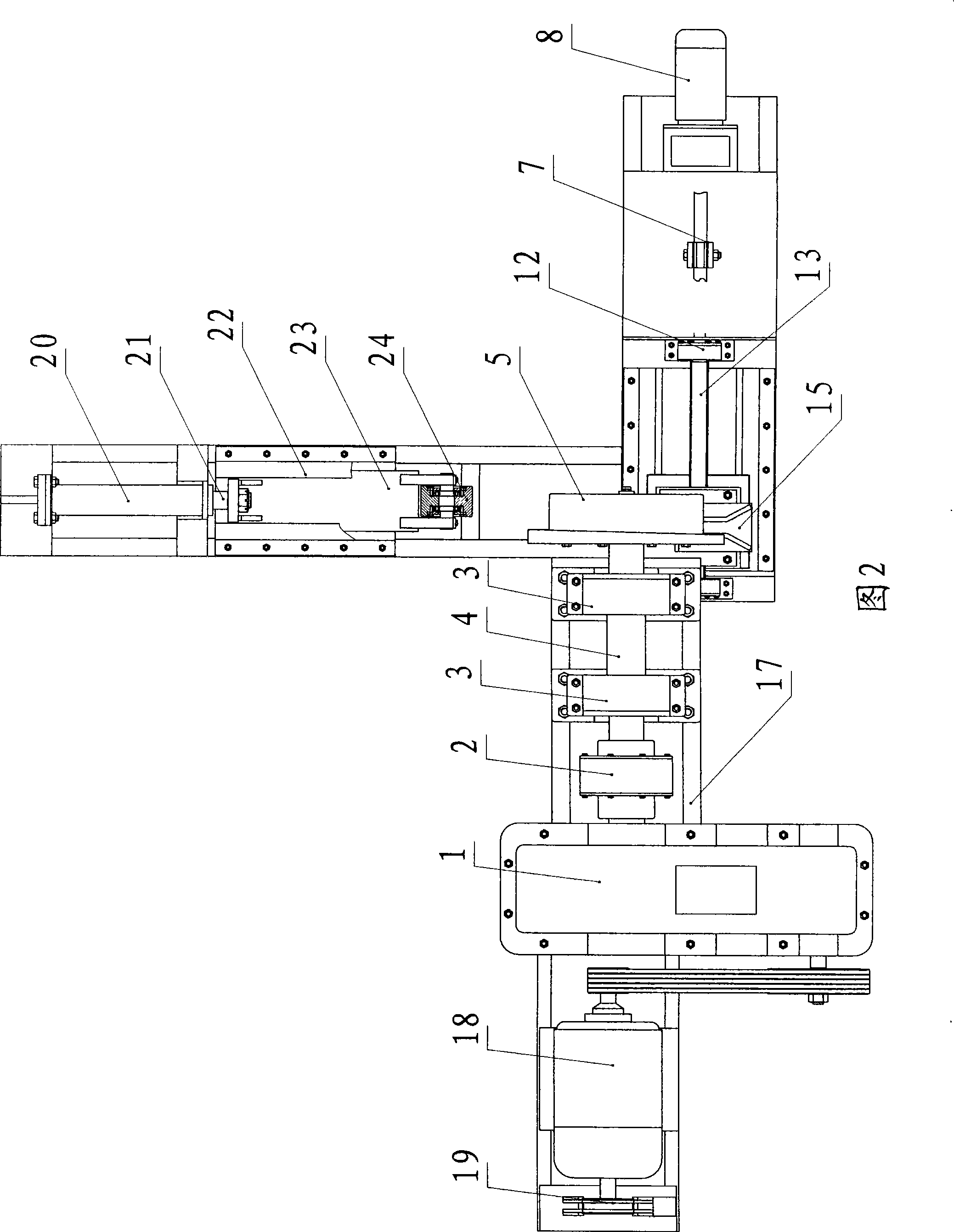

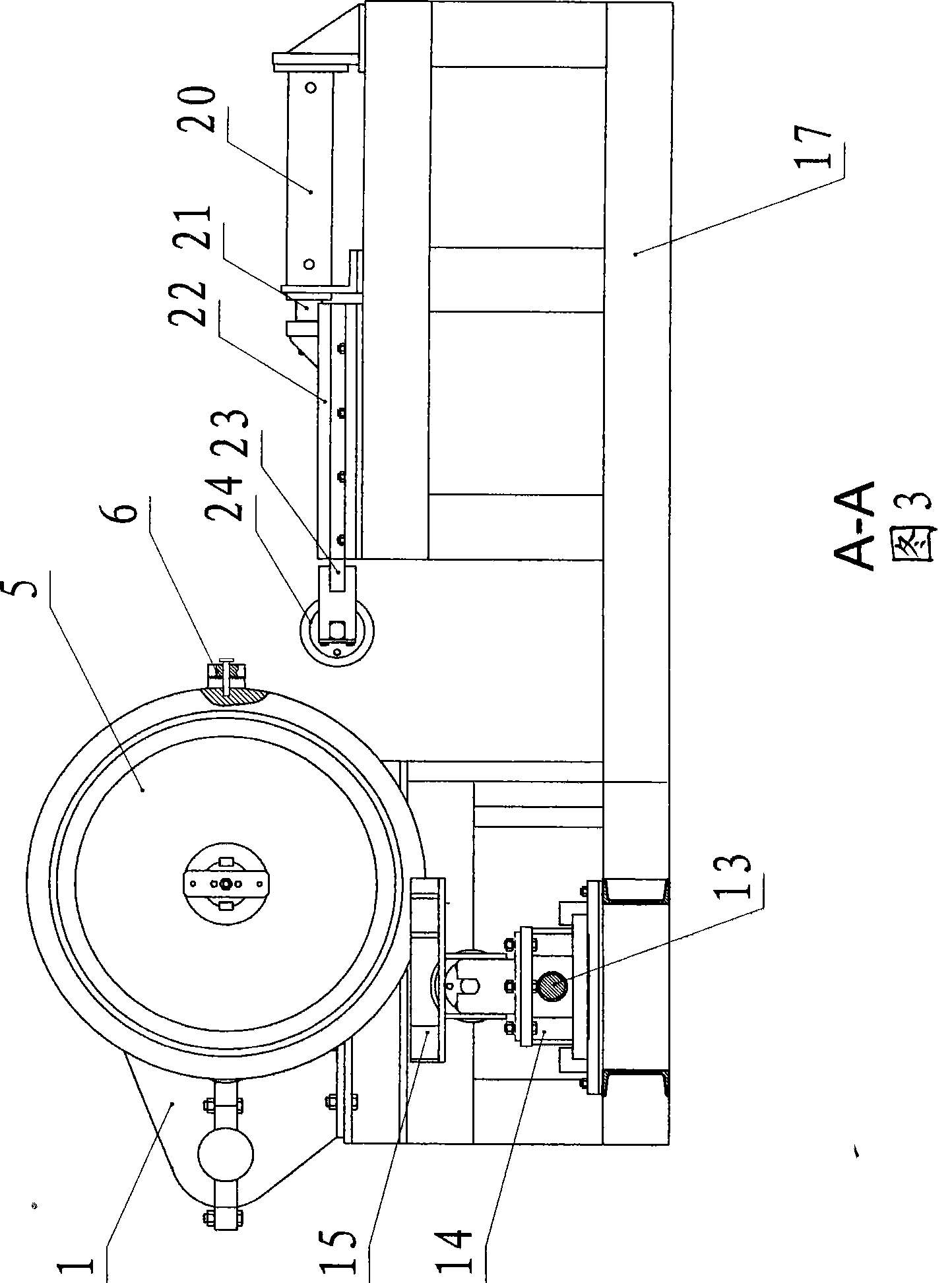

[0020] Embodiment one: see figure 1 , figure 2 , image 3 , a flange blank hot coiling machine in the figure, including a frame 17, and a first power machine 18 fixedly installed on the frame 17, a first speed reducer 1; a first bearing box 3, a flat steel guide device 14, A main shaft 4 passes through and is installed in the first bearing box 3, one end of the main shaft is connected to the output shaft of the first reducer 1 through the first coupling 2, and the other end is provided with a disc-shaped crimping mold 5, the said End clamps 6 are installed on the edge of the disc-shaped crimping mold 5, and the disc-shaped crimping mold 5 is provided with a hydraulic pressing device in approximately the same plane direction, and the end of the pressing device is provided with a pressing wheel 24.

[0021] Described flat steel guiding device 14 is installed in disc-shaped crimping mold 5 bottoms, is provided with the guide groove 15 that direction is approximately parallel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com