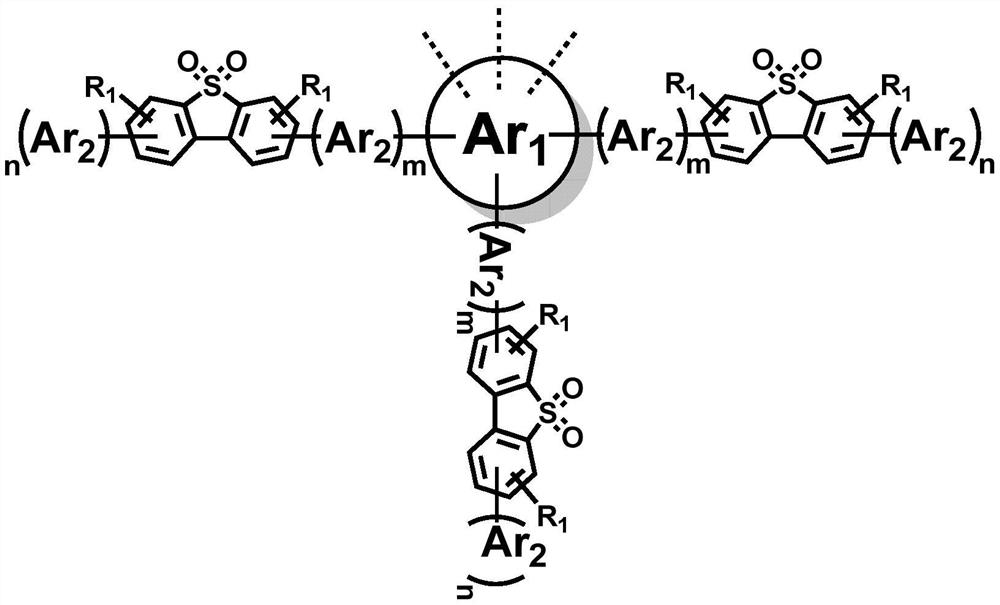

A star-shaped blue fluorescent molecule and its synthesis method and application

A technology of blue fluorescence and synthesis method, applied in the field of organic optoelectronics, can solve the problems of poor repeatability, non-uniform molecular weight, uncertain structure, etc., and achieve the effects of good film formation, uniform molecular weight and definite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Compound 1

[0041] Under nitrogen protection, add 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9,9- Dihexylfluorene (5.86g, 10mmol), 2-bromo-9,9-dihexylfluorene (4.13g, 10mmol), potassium carbonate (3.45g, 25mmol), tetrakis(triphenylphosphine) palladium (0.58g, 0.5 mmol), 12ml deionized water and 120ml toluene, heated to 80°C for 12 hours. After the reaction was completed, the product was extracted with dichloromethane, washed three times with saturated aqueous sodium chloride solution, and after removing the organic phase solvent, the crude product was purified by column chromatography using petroleum ether as eluent to obtain 6.50 g of a near-white solid, with a yield of 82%. . 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and its chemical reaction equation is as follows:

[0042]

Embodiment 2

[0044] Under nitrogen protection, add 2-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9,9-dihexylfluorene into a 300ml two-necked bottle (4.60g, 10mmol), 2-bromo-7-iodo-9,9-dihexylfluorene (5.39g, 10mmol), potassium carbonate (3.45g, 25mmol), tetrakis(triphenylphosphine) palladium (0.58g, 0.5mmol), 12ml deionized water and 120ml toluene, heated to 80°C for 12 hours. After the reaction was completed, the product was extracted with dichloromethane, washed three times with saturated aqueous sodium chloride solution, and after removing the organic phase solvent, the crude product was purified by column chromatography using petroleum ether as eluent to obtain 5.22 g of a near-white solid, with a yield of 70%. . 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and its chemical reaction equation is as follows:

[0045]

Embodiment 3

[0047] Preparation of Compound 4

[0048] (1) Preparation of Compound 3

[0049] Under nitrogen protection, 2,7-dibromo-9,9-dihexylfluorene (4.92 g, 10 mmol) and 120 ml of anhydrous tetrahydrofuran were added to a 300 ml two-necked flask, and the temperature was lowered to -78°C. Slowly add n-butyllithium n-hexane solution (5.5ml, 11mmol) dropwise, continue to stir at -78°C for half an hour, then add trimethylsilyl chloride (1.63g, 15mmol), and slowly rise to room temperature for 8 hours . Quench the reaction with a small amount of water, extract the product with dichloromethane, wash with saturated sodium chloride solution three times, remove the solvent of the organic phase under reduced pressure, and purify the crude product with a silica gel column (eluent is petroleum ether) to obtain a yellow oily liquid 4.27g, 88% yield. 1 HNMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product.

[0050] (2) Preparation of Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com