Novel aluminium profile divided-chamber aging furnace

An aluminum profile, split-chamber technology, used in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of short profiles, large space occupied by machine lines, poor temperature uniformity, etc., to achieve strong operability and practicability. , low operating cost, the effect of increasing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

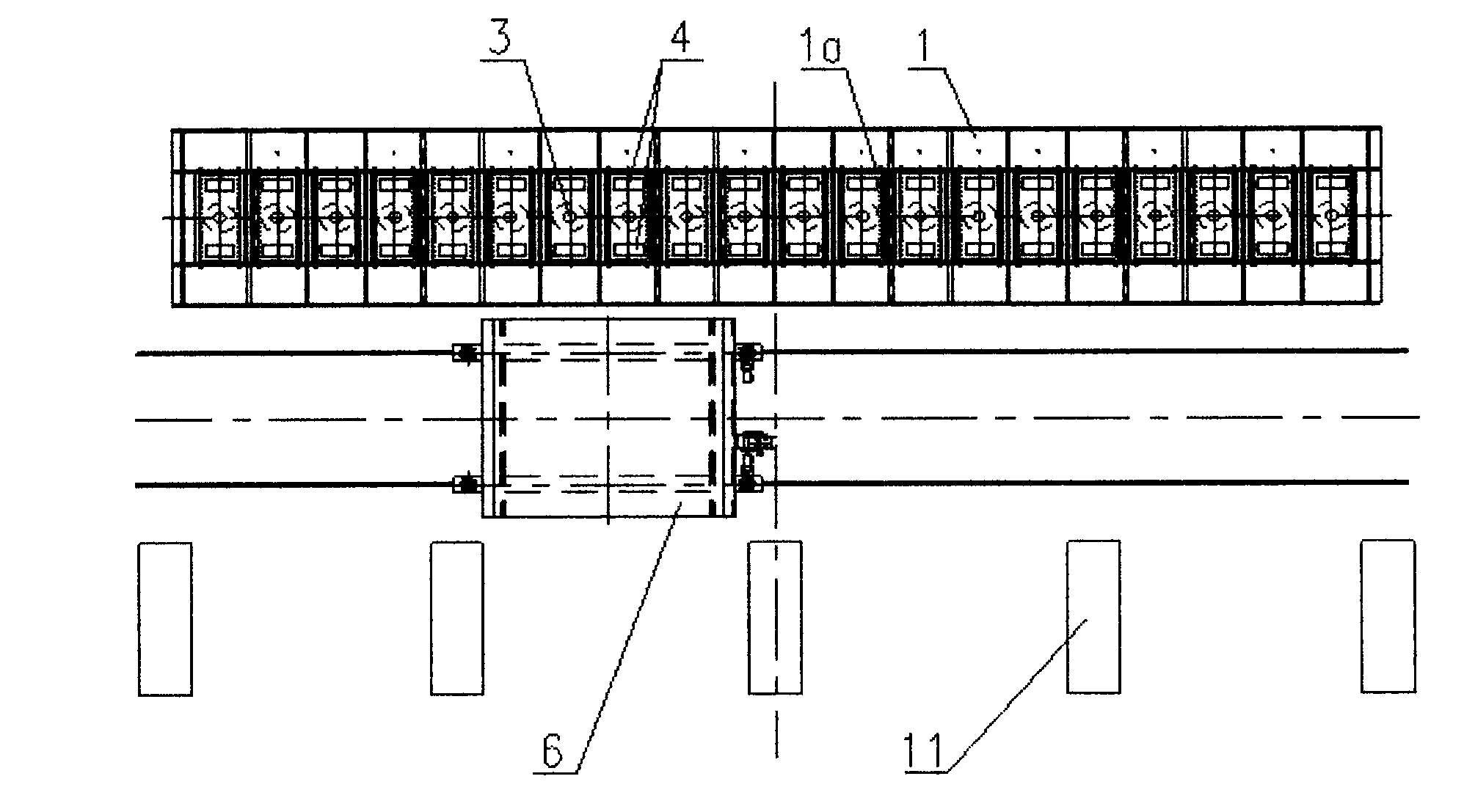

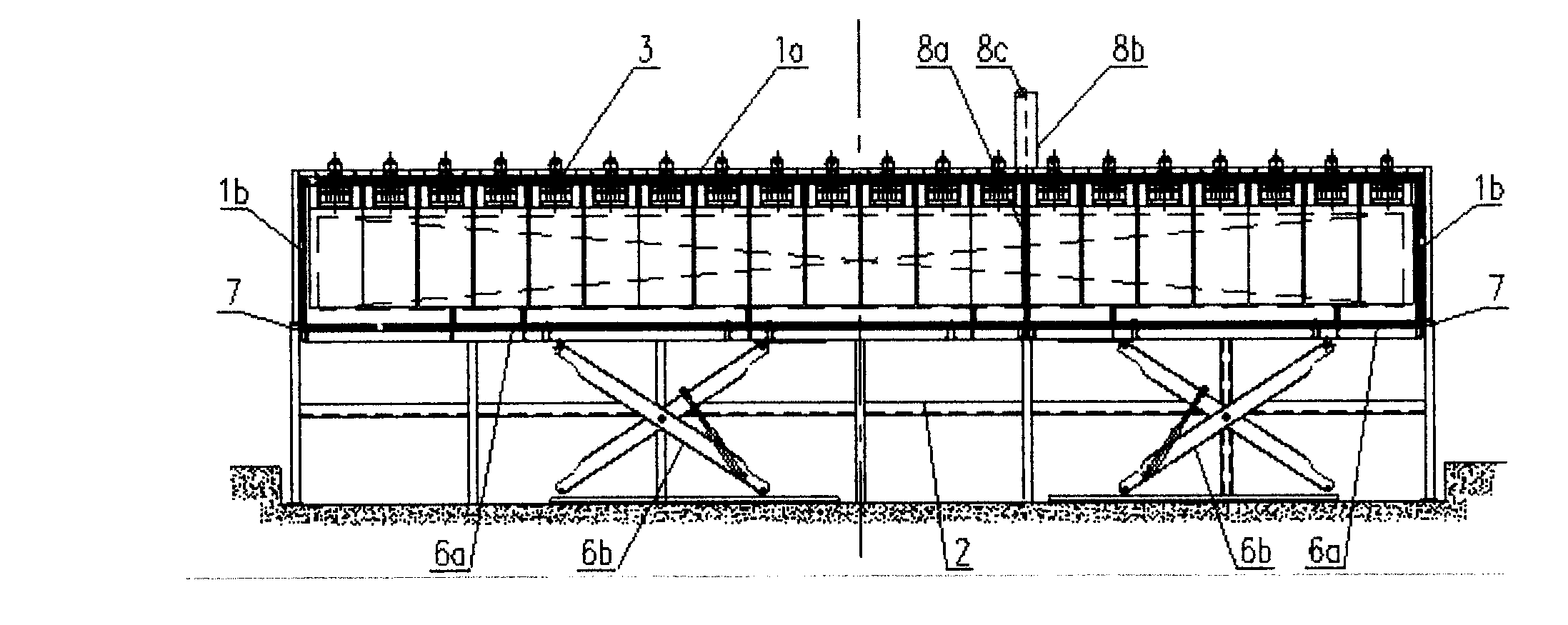

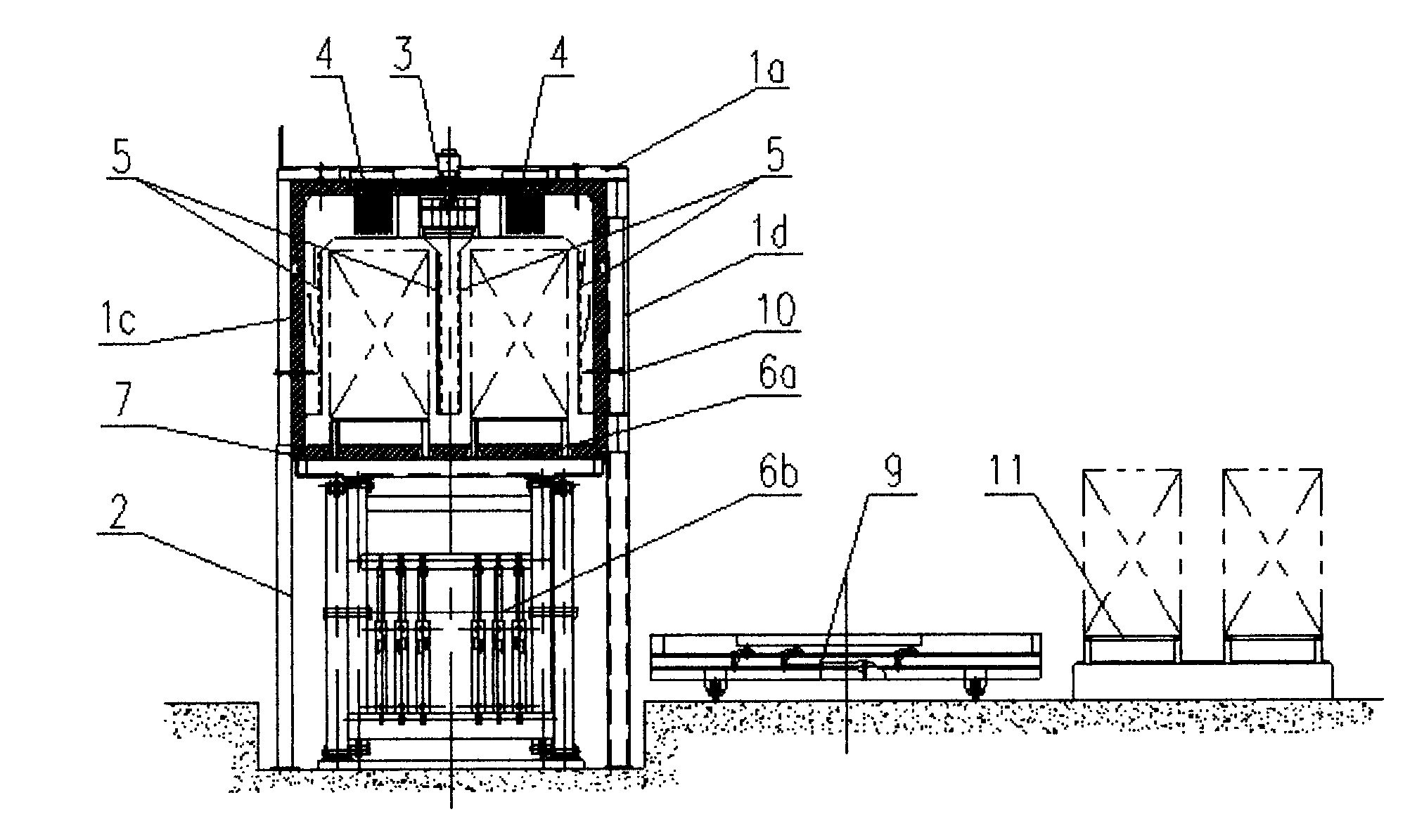

[0028] see figure 1 , figure 2 with image 3 As shown, a new type of split-chamber aging furnace for aluminum profiles, including a furnace body 1, a furnace body support 2, a circulating fan 3, a heater 4, a furnace diversion system 5, a bottom-mounted lifting furnace door mechanism 6, a furnace door Sealing 7, chamber divider device 8 and furnace temperature monitoring device 10, etc., the furnace body 1 is a rectangular hollow structure, consisting of front and rear end walls 1b, outer side walls 1c, charging side walls 1d and furnace roof 1a, and The furnace body support 2 is supported in the air, the furnace body support 2 is installed on the basis of the workshop, the circulation fan 3 and the heater 4 are located on the furnace roof 1a, and the bottom-mounted furnace door lifting mechanism 6 is located on the Bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com