Thermal insulation type automatic snow removal runway

An automatic, runway technology, applied to roads, roads, pavement details, etc., can solve the problems of poor cleaning effect, inconvenient travel, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

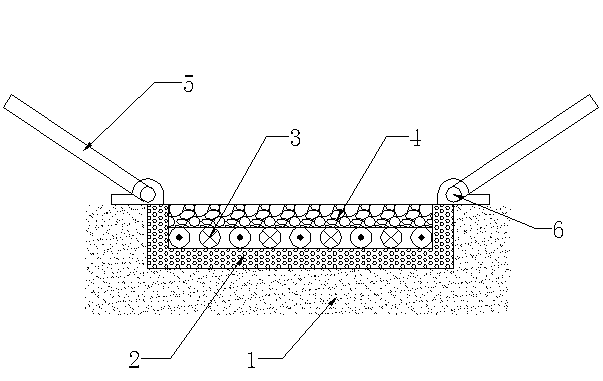

[0009] The thermal insulation type automatic snow removal runway of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] As shown in the figure, the thermal insulation type automatic snow removal runway of the present invention includes a pouring bottom layer 1 for road paving, and a layer of thermal insulation layer 2 is covered on the pouring bottom layer 1. The thermal insulation layer provided can prevent the rapid loss of heat and has a certain concentration. Thermal effect, heating pipe 3 is laid on the top of the insulation layer 2, and a layer of concrete layer 4 is covered on the top of the heating pipe 3 as the road surface. Both sides of the concrete layer 4 are hinged with insulation cover plates 5 at the same time. The hinged shafts 6 are respectively provided with an electric overturn transmission mechanism (not shown in the figure) that can drive the heat preservation cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com