A hydraulic and mechanical dual power output device

A dual power output, mechanical technology, applied in the direction of mechanical equipment, machines/engines, etc., can solve the problems of hydraulic free-piston engines with unfixed top dead center, single output power, and unfixed top dead center, etc., to achieve high efficiency and reliability Conversion process inside the power machine, simple structure, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

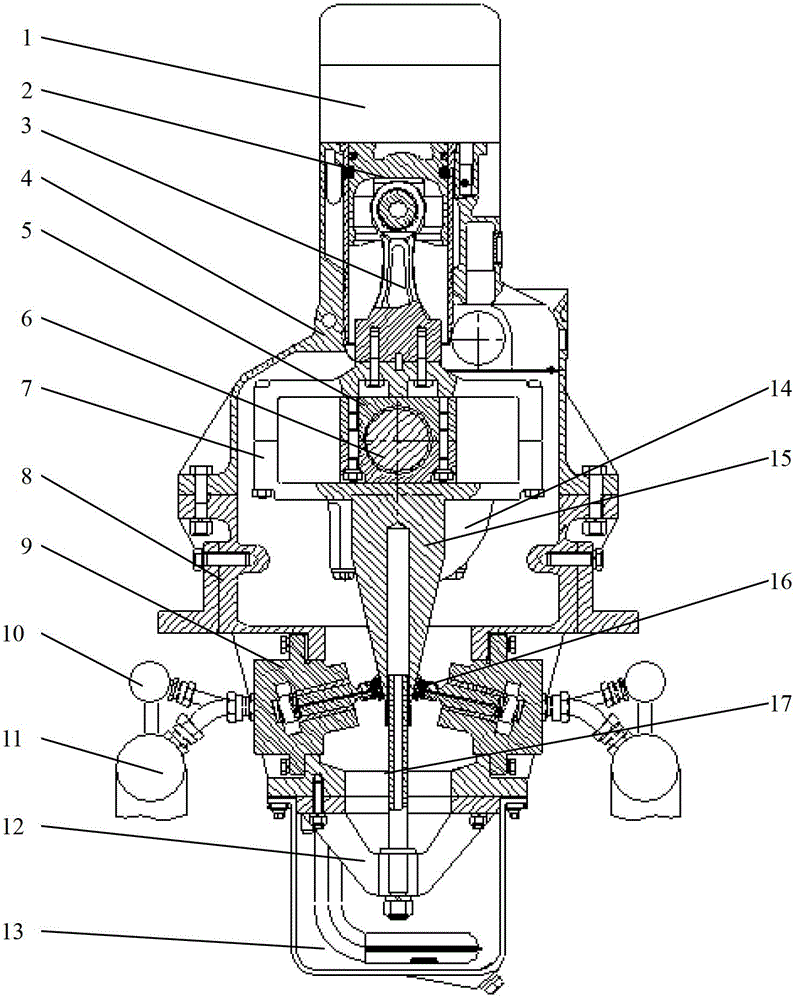

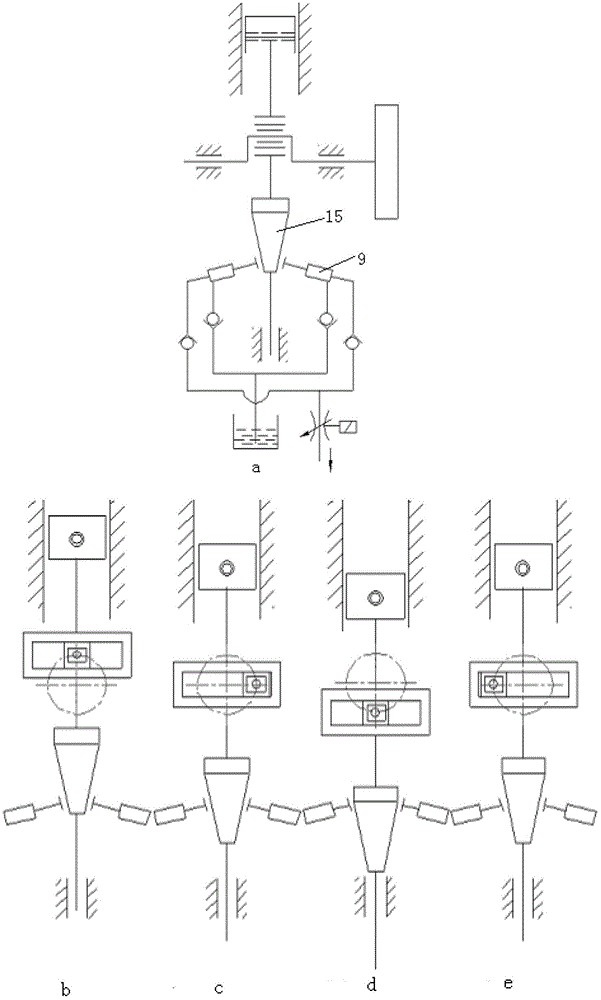

[0013] The main structure of this embodiment includes a cylinder head 1, a piston 2, a connecting rod 3, a cylinder block 4, a slider 5, a crank pin 6, a slider groove 7, a lower body 8, a plunger hydraulic pump 9, an oil outlet pipeline 10, Oil inlet pipeline 11, guide rod bracket 12, oil pan 13, crankshaft 14, hydraulic pump drive mechanism 15, slipper shoe 16 and guide rod 17; cylinder head 1 is fixedly installed on the top of cylinder block 4; oil pan 13 is installed on the bottom On the body 8, the cylinder head 1, the cylinder block 4, the lower body 8 and the oil pan 13 are combined to form an upper and lower closed body group structure; the piston 2 is hinged with the connecting rod 3 through the piston pin, and the hinged connecting rod 3 and the piston 2 are connected from the The top of the cylinder block 4 penetrates, and the connecting rod 3 is fixedly connected with the upper half of the slider groove 7; Make horizontal movement; the lower part of the slider groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com