Power loss recycling device

A technology of power loss and transmission, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as energy waste, and achieve the effects of enhanced safety and stability, small size, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

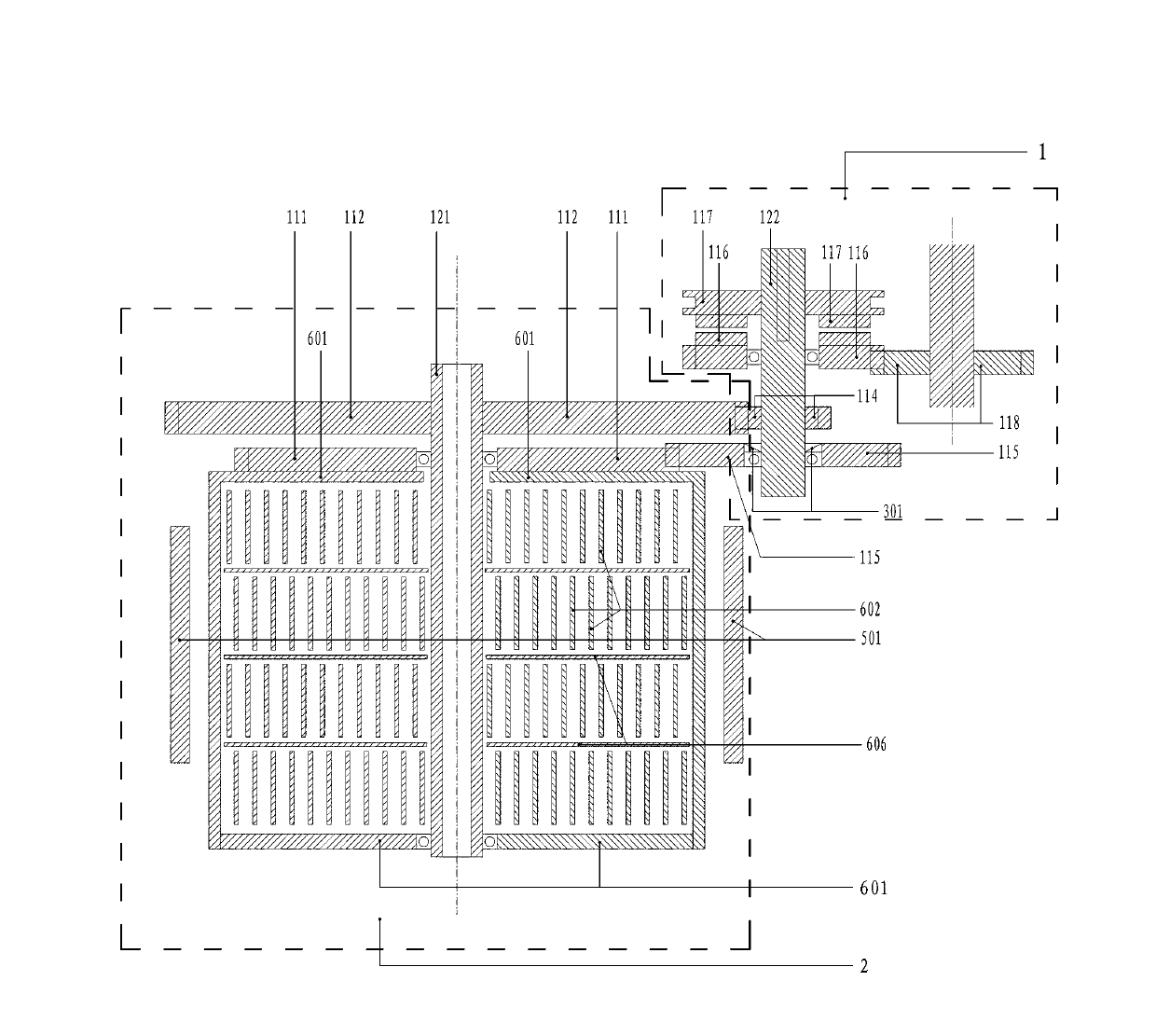

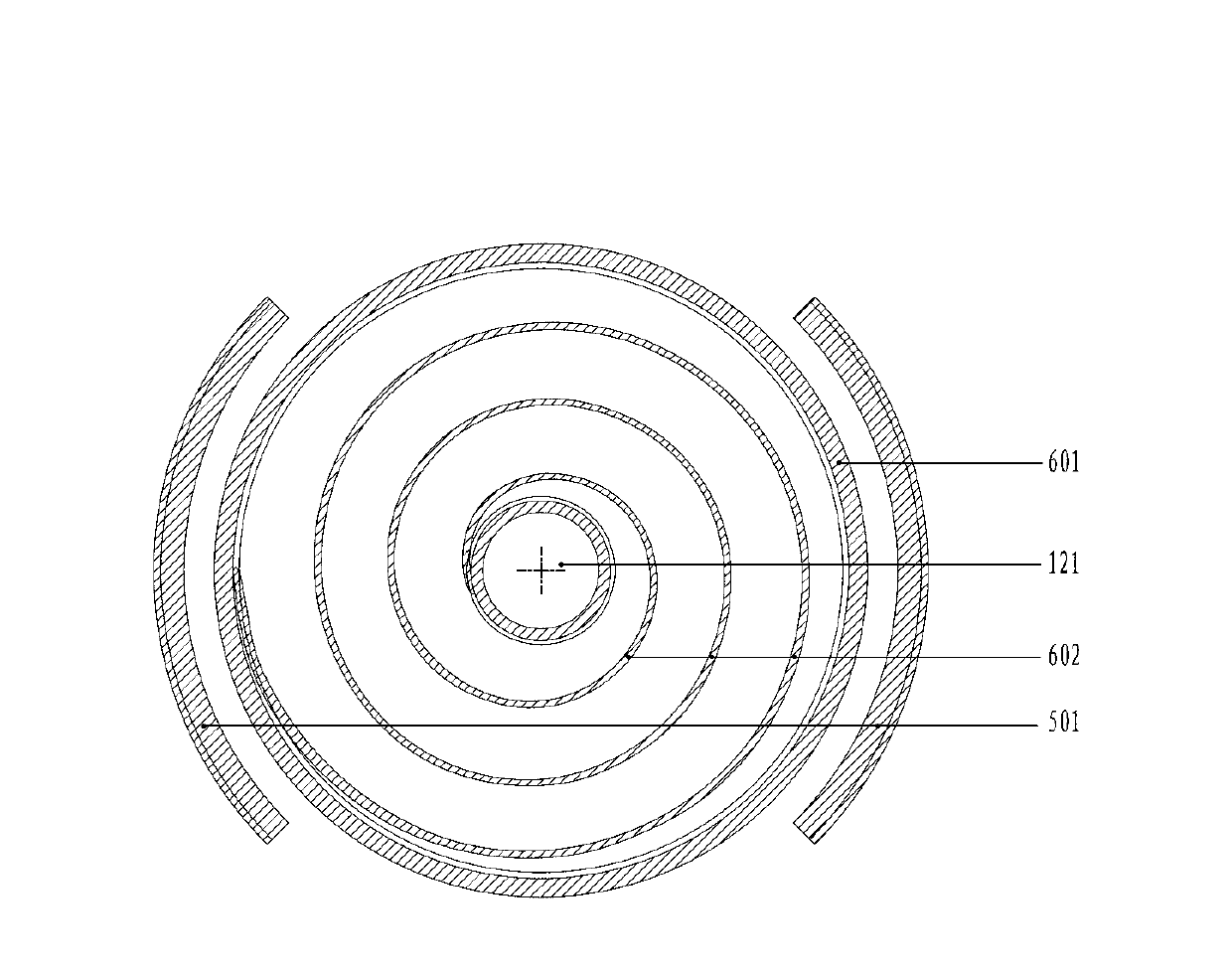

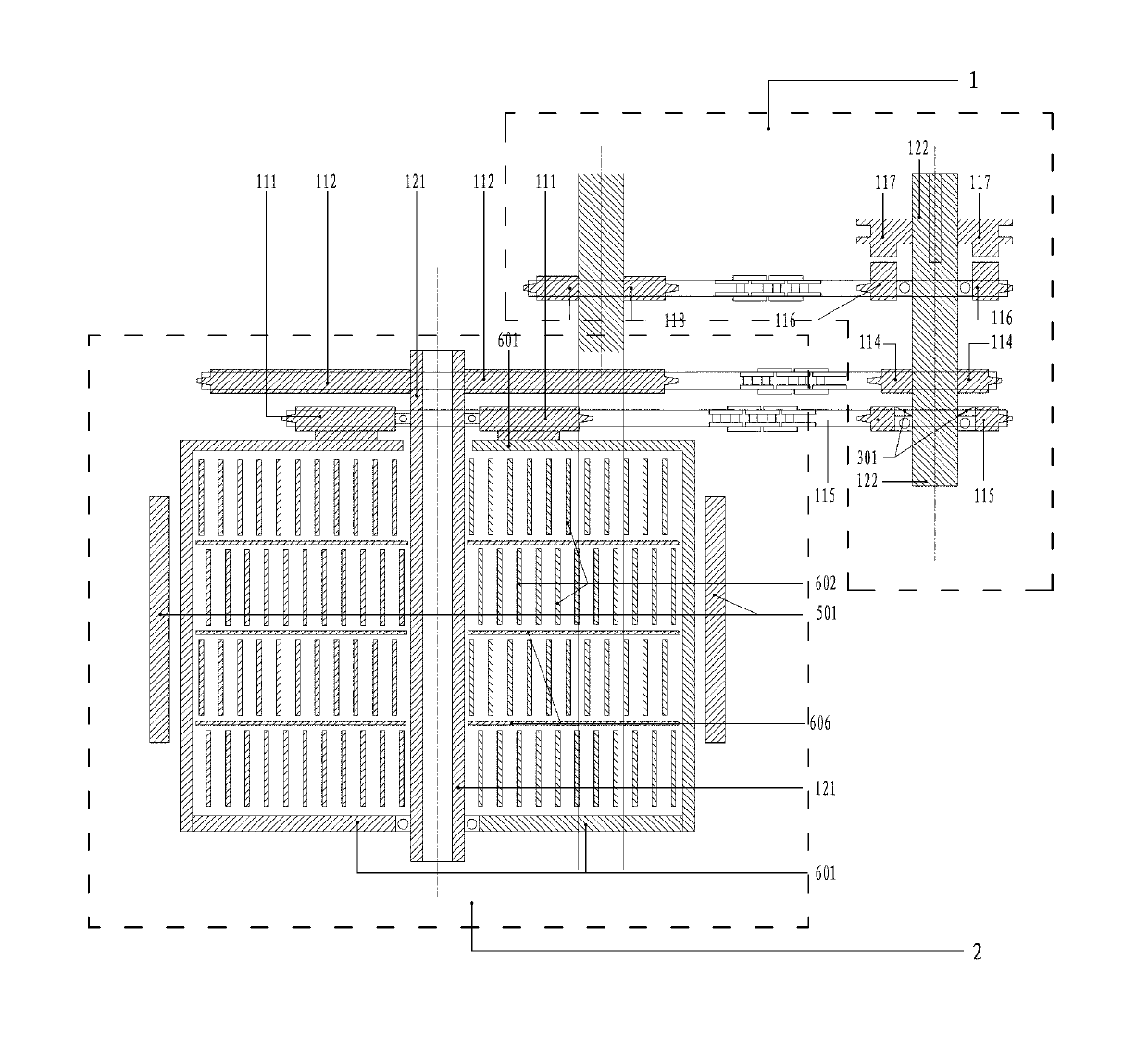

[0037] Such as figure 1 and figure 2 Shown includes transmission 1 and energy storage 2;

[0038] The transmission device 1 includes: power transmission wheel I 118 (here the power transmission wheel I 118 can be a transmission wheel fixed on a certain section of the drive shaft between the motor vehicle gearbox and the differential, or directly use the matching transmission wheel in the differential ), the primary drive shaft 122, the slip transmission wheel II 117, the transmission wheel III 116, the transmission wheel IV 114 and the transmission wheel V 115; the slip transmission wheel II 117 is fixed on the primary drive shaft 122, and the transmission wheel III 116 is fixed on the primary drive shaft through bearings On the rotating shaft 122, the adjacent end surfaces of the sliding transmission wheel II 117 and the transmission wheel III 116 are processed with meshing teeth; the power transmission wheel I 118 cooperates with the transmission wheel III 116; the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com