On-site test method and device for construction enclosure construction member horizontal thrust performance

A technology for building enclosure and horizontal thrust, which is used in measuring devices, testing of machine/structural components, instruments, etc., and can solve the problems of lack of on-site detection and lack of resistance to horizontal thrust deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

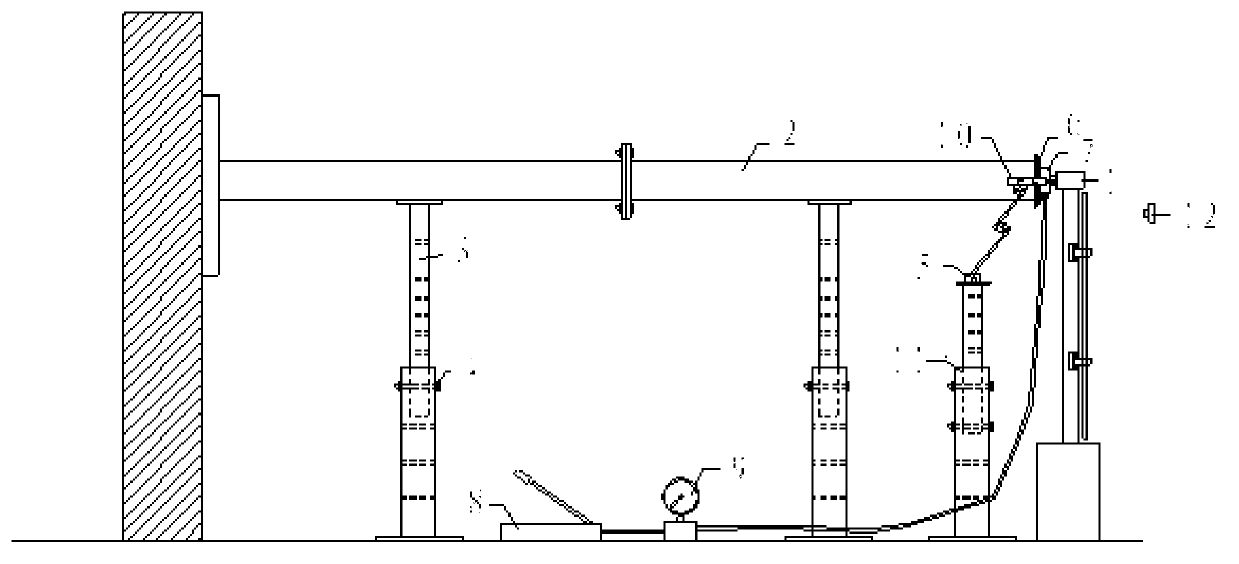

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 Shown: an on-site detection device for the horizontal thrust performance of building envelope components, including a manual oil pump 8, an oil pressure gauge 9, a jack 7, a reaction beam 2, a reaction column 3, a displacement meter bracket 11, a digital display displacement meter 10, Magnetic base 5 and digital camera 12 are installed with a reaction frame formed by welding reaction beam 2 and reaction column 3 between the building wall and the handrail position of the building enclosure component 1 to be checked, on the reaction column 3 There is an adjusting bolt 4 for adjusting its height, and a plug piece 6 is used to fix the jack 7 between the handrail of the building enclosure component 1 to be inspected and the reaction beam 2. The jack 7 is connected to the manual oil pump 8 by the oil pipe, and the manual oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com