Three-dimensional microcomputer electric transducer

A technology of micro-electromechanical sensors and three-dimensional coordinates, which is applied to piezoelectric devices/electrostrictive devices, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., and can solve problems such as inability to simultaneously sense sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

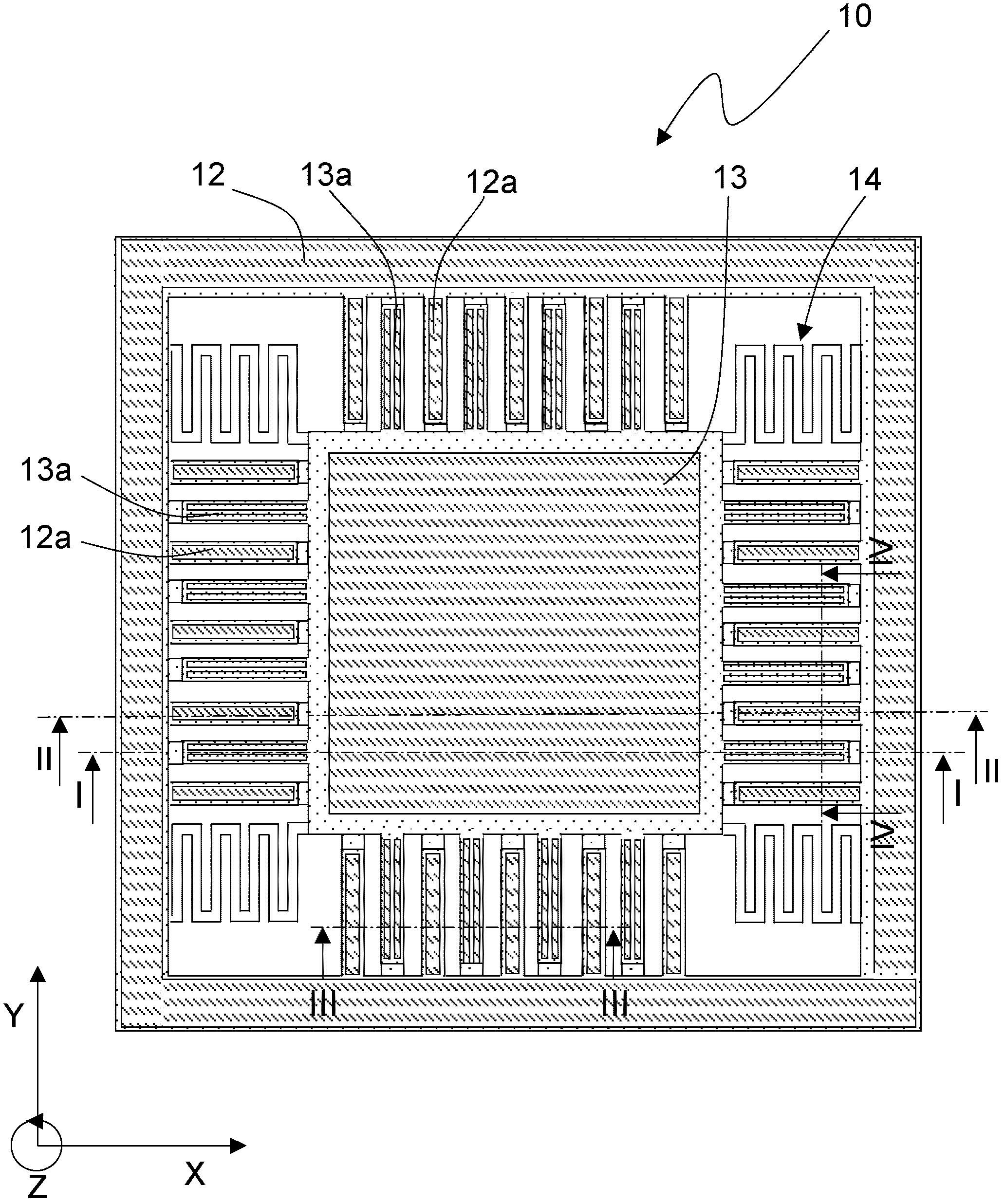

[0065] figure 1 A top view of a three-axis MEMS sensor according to an embodiment of the present invention is shown. The three-axis MEMS sensor 10 includes a substrate 11 (see Figure 2A ), a fixed frame portion 12, a mass block 13 and a plurality of spring members 14. The fixed frame portion 12 is fixed on the base plate 11 and surrounds the proof mass 13 , but is not limited to the enclosed wall shape in the drawing, and may also be multiple columns or multiple walls. A plurality of springs 14 connect the outer fixed frame portion 12 and the central mass block 13 , and enable the mass block 13 to move in-plane and out-of-plane relative to the base plate 11 through its elasticity. Here, the co-planar motion refers to the motion on the XY plane (parallel to the substrate 11 ), and the out-of-plane motion refers to the motion component on the Z axis.

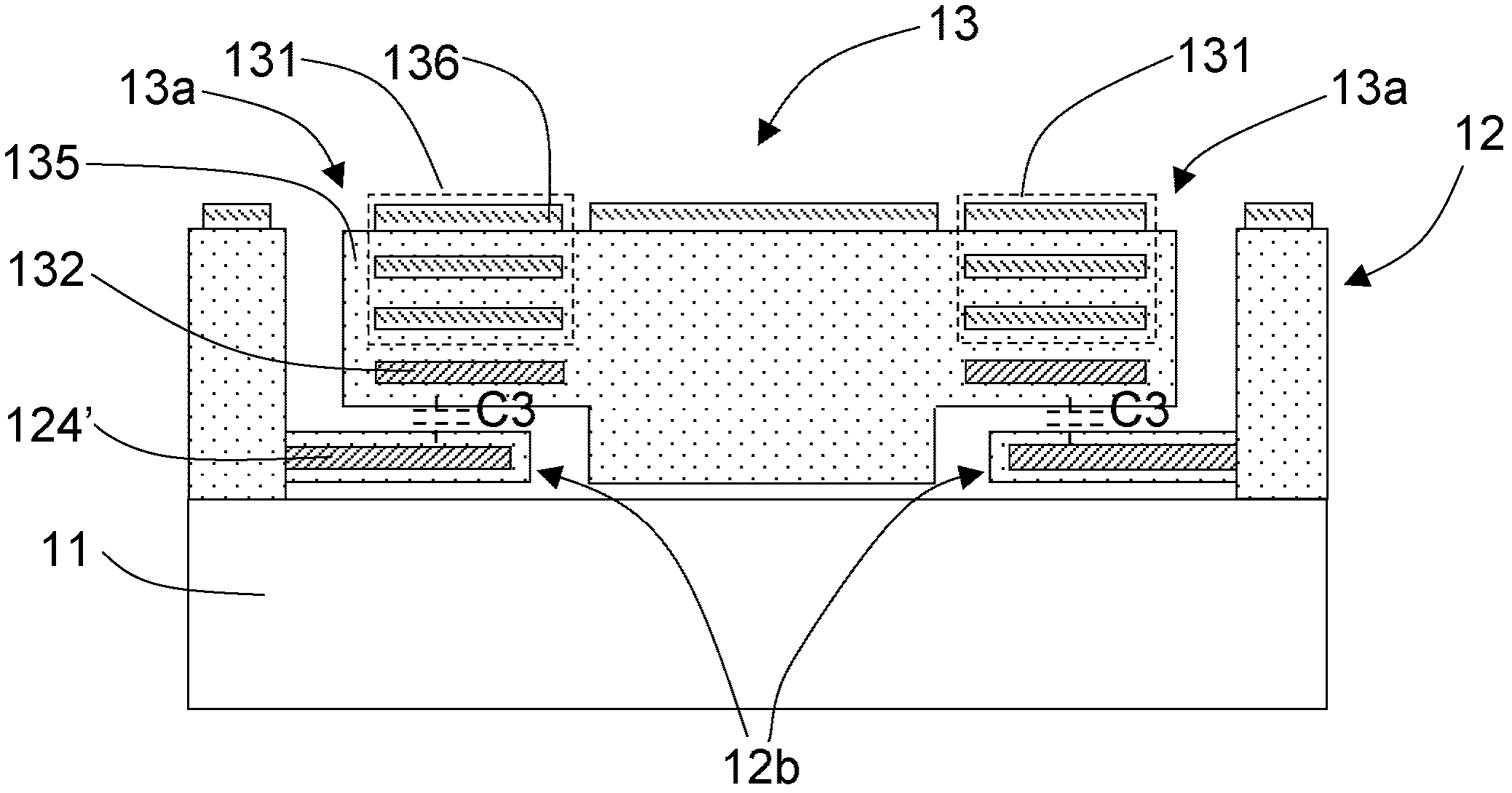

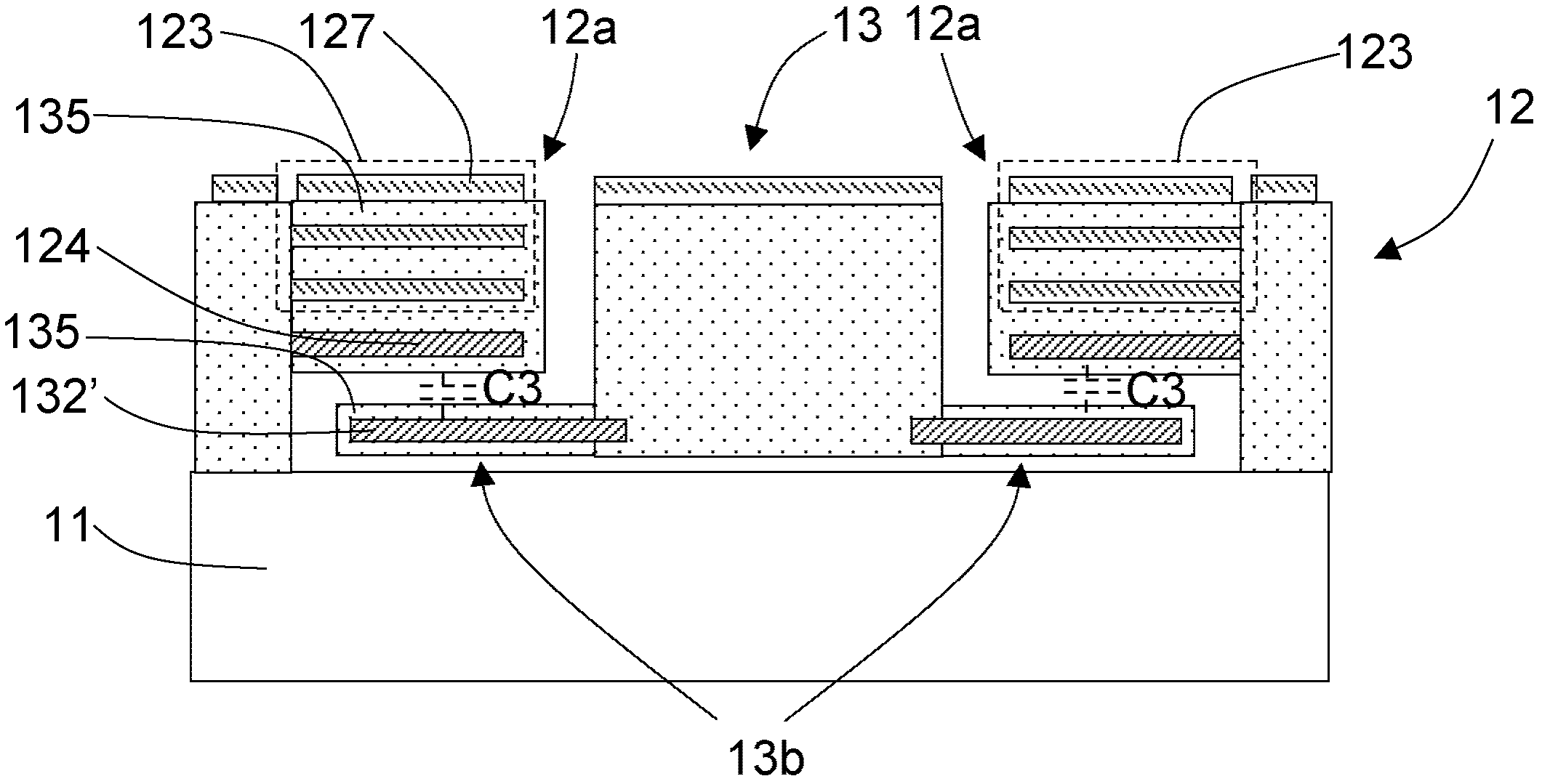

[0066] Figure 2A for along figure 1 The cross-sectional view of the I-I section line, and Figure 2B for along figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com