Method and system of analyzing dredging operation of cutter-suction dredger

An operation process and cutter suction ship technology, applied in the field of analysis of cutter suction ship dredging construction operation process, can solve the problem that the guiding significance of ship time utilization rate and productivity is not obvious, and the number and number of productive shutdown processes cannot be accurately analyzed. Occupying time, unable to provide accurate important parameter data, etc., to achieve the effect of improving ship time utilization and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

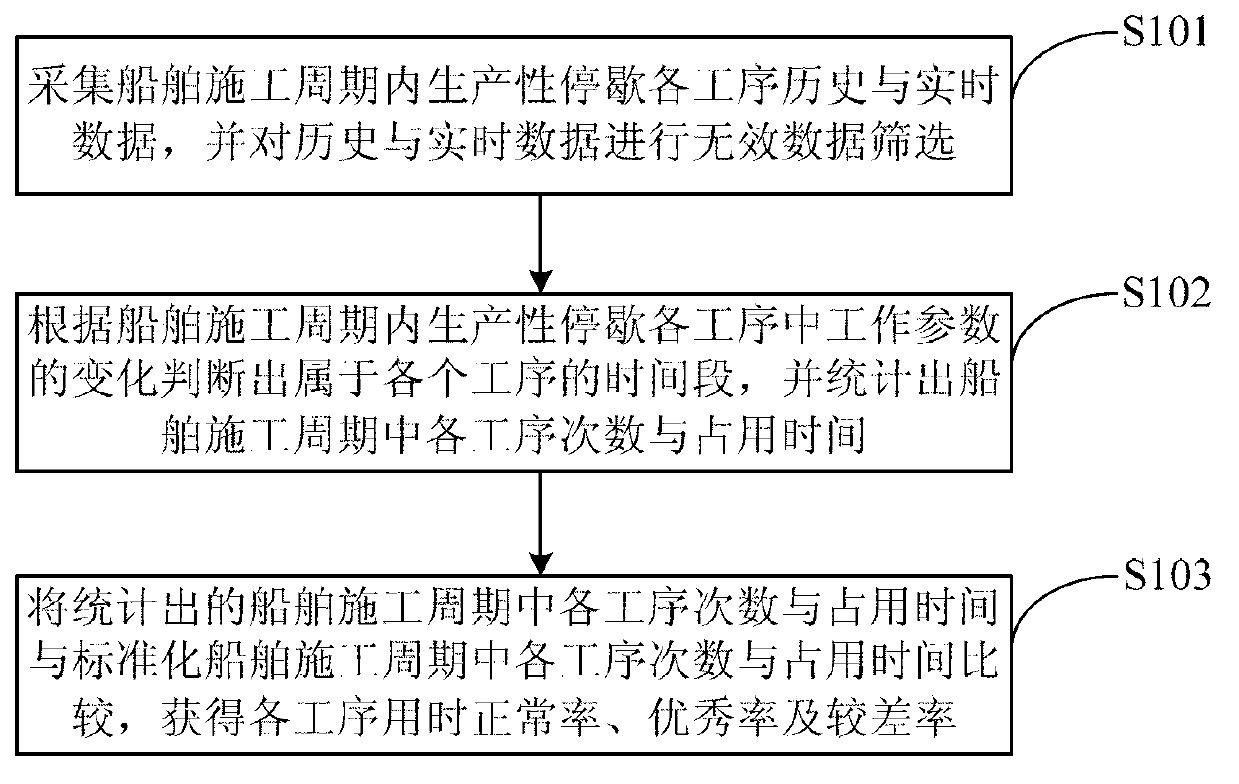

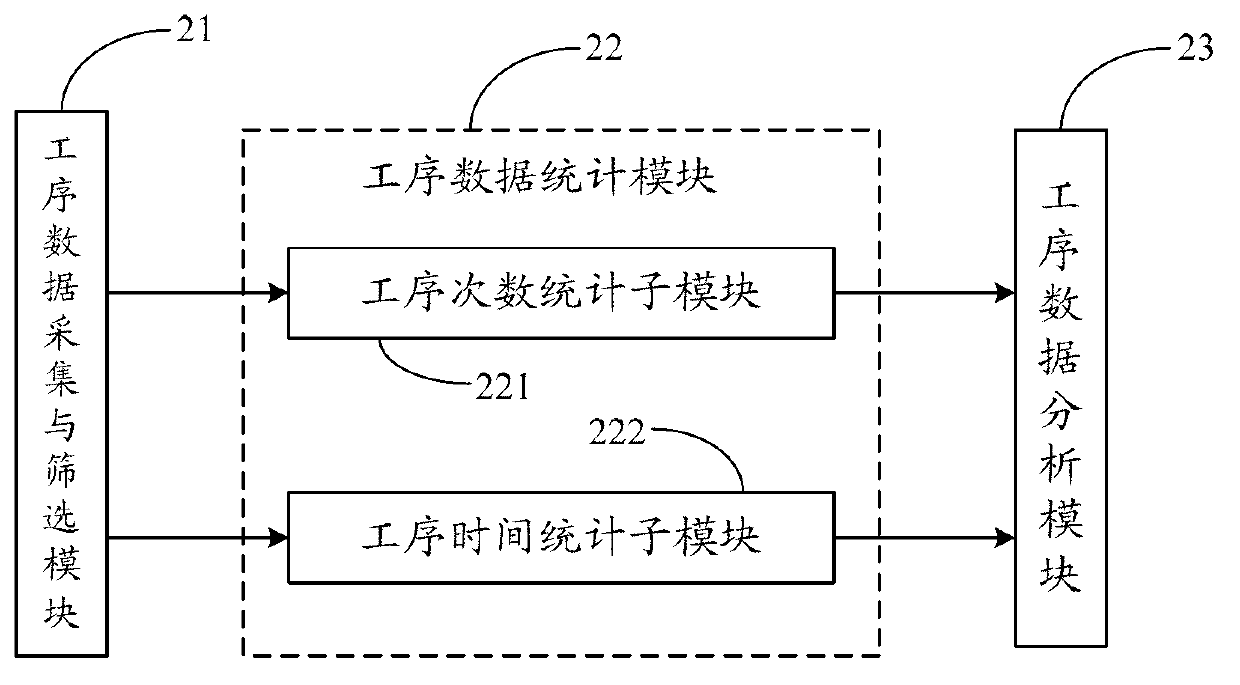

[0038] figure 1 It shows the implementation process of the method for analyzing the dredging construction process of the cutter suction ship provided by the embodiment of the present invention. The method includes the following steps:

[0039] Step S101, collecting the historical and real-time data of each process during the productive shutdown of the ship construction period, and filtering the collected historical and real-time data for invalid data;

[0040] Step S102, judging the time period belonging to each process according to the change of working parameters in each process of productive stop in the ship construction period, and counting the number of times and occupied time of each process in the ship construction cycle;

[0041] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com