Subcritical wrapping layer of transmutation of pressure pipe type long-lived fission product

A technology of fission products and pressure tubes, which is applied in the direction of nuclear power generation, climate sustainability, moderator/core structure, etc., can solve the problems of adding mixed reactors and little operating experience, and achieve increased energy magnification, high and slow The effect of improving the chemical ability and improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

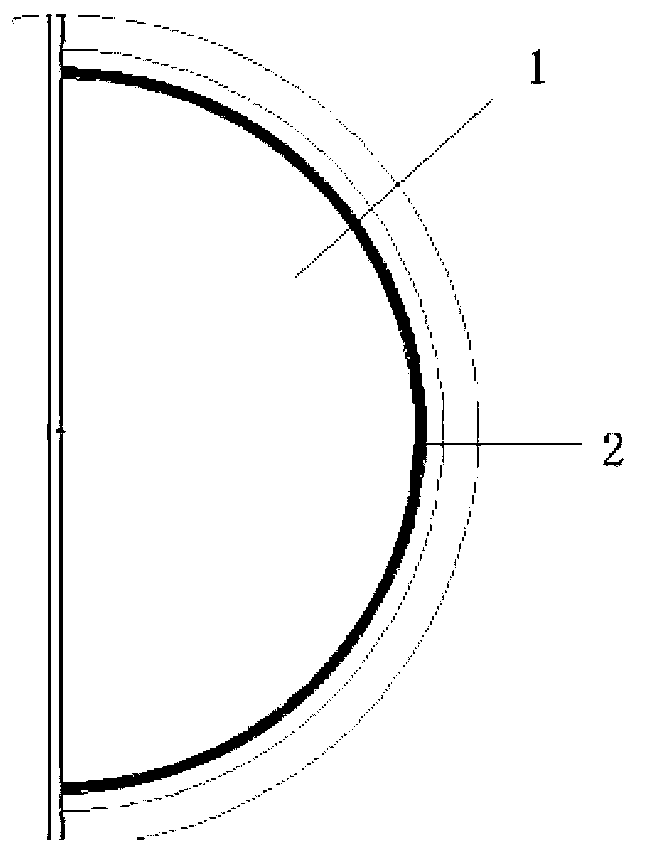

[0025] Such as figure 1 Shown is a schematic cross-sectional view of a fusion-driven subcritical hybrid stack, in which the fusion neutron source 1 is covered with a subcritical cladding 2 .

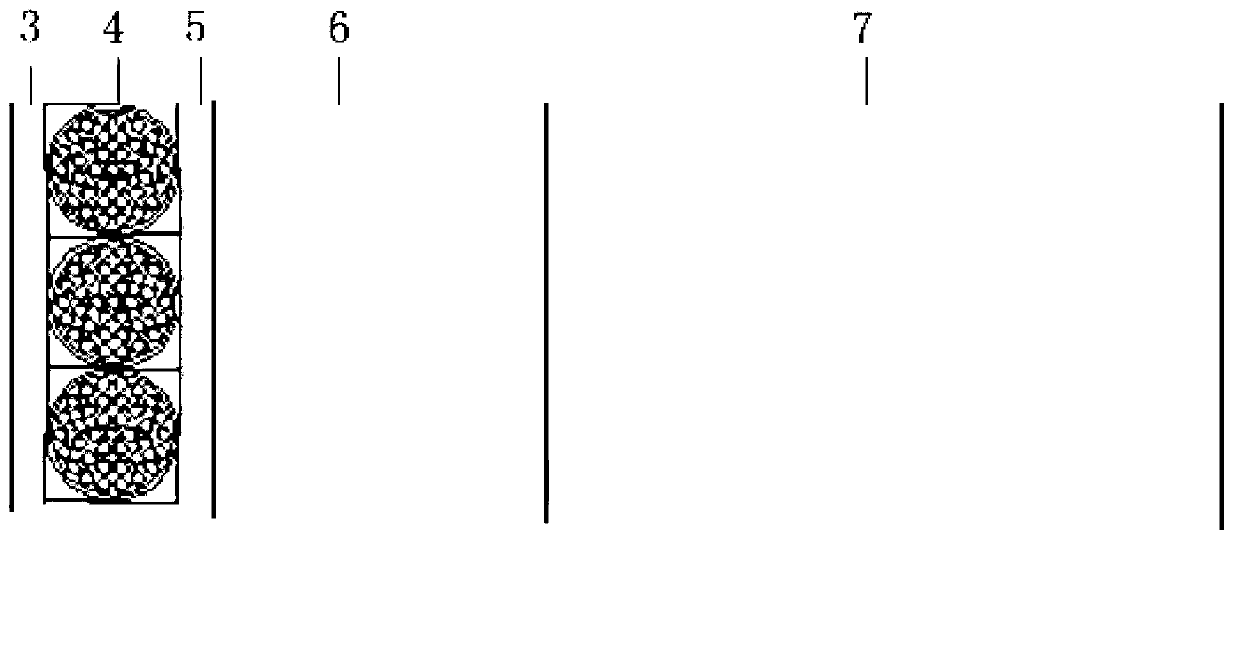

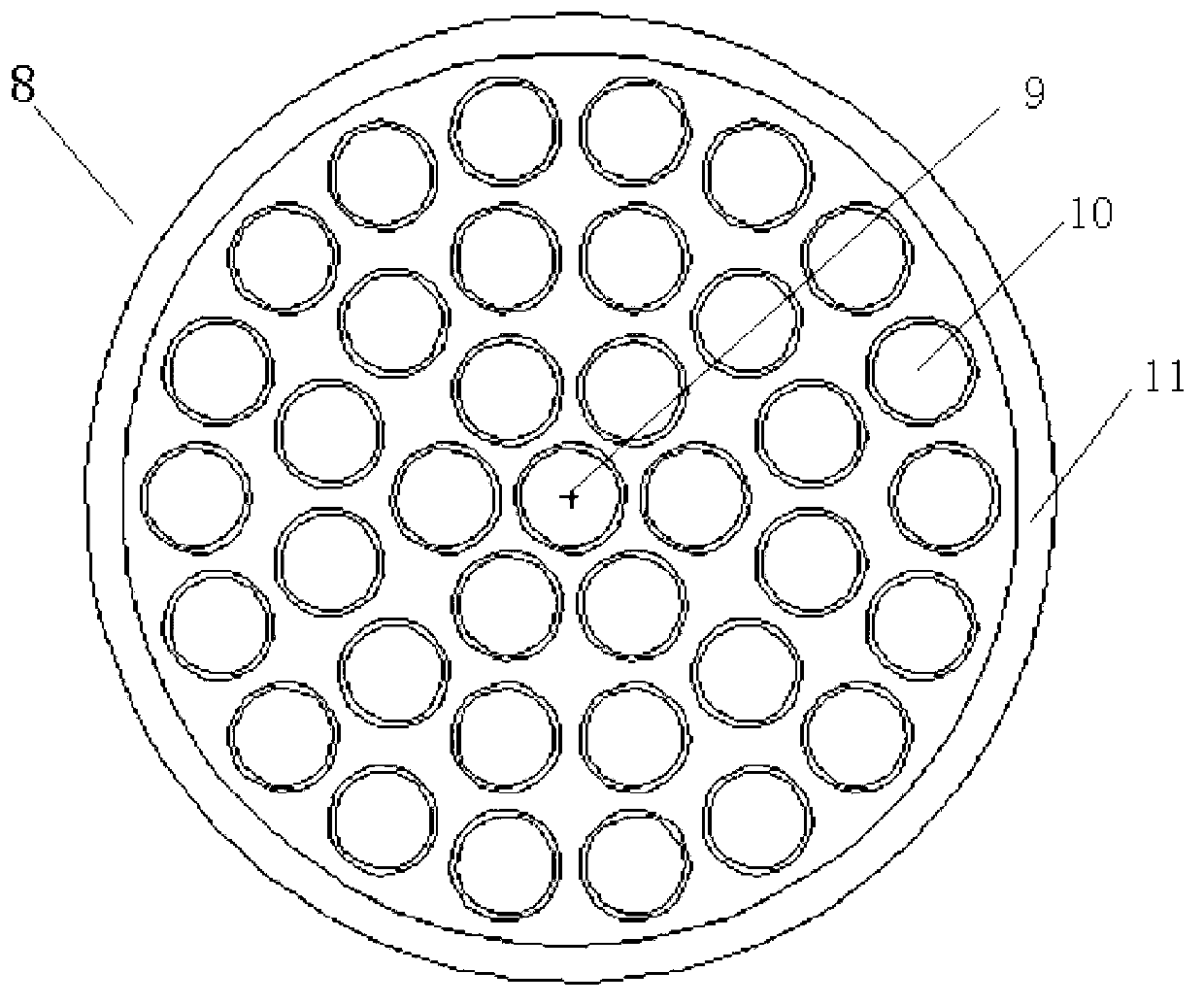

[0026] Such as figure 2 As shown, the subcritical cladding for the transmutation of a pressure tube type long-lived fission product of the present invention includes a first wall 3, a transmutation zone 4, a structural wall 5, a tritium breeding zone 6 and a shielding layer 7 from the inside to the outside. The transmutation zone 4 is cooled by high-pressure light water, and the transmutation zone 4 uses a pressure tube fuel assembly 8 . The thickness of the first wall 3 can be reduced to 20 mm because the pressure tube fuel assembly 8 bears the pressure of high-pressure light water.

[0027] Preferably, a row of pressure tube fuel assemblies 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com