Solar condenser photovoltaic power generation components

A solar concentrating and solar photovoltaic technology is applied in the field of solar concentrating photovoltaic power generation components to achieve the effects of compensating for inaccuracy, high photoelectric conversion rate, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

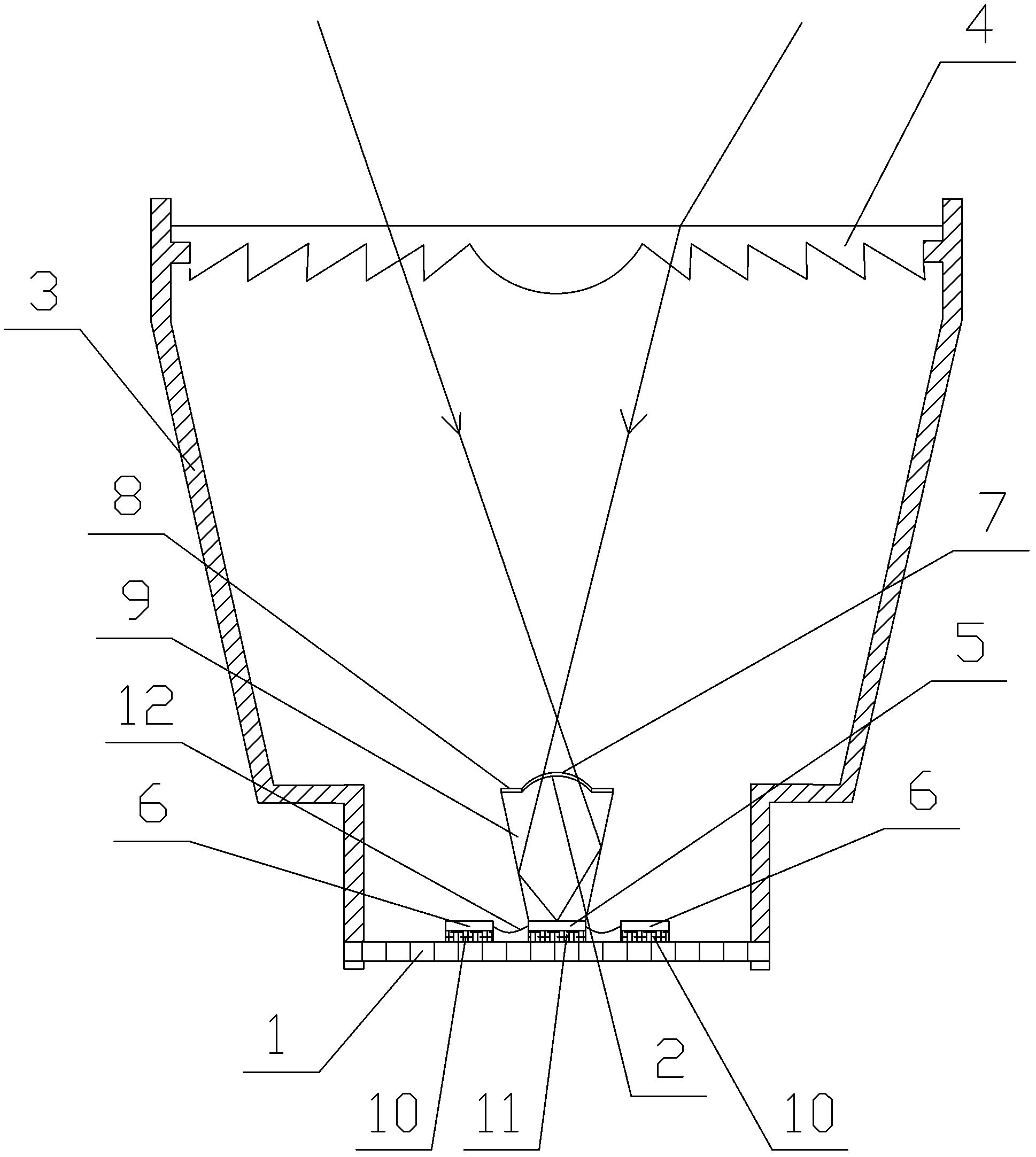

[0024] Such as figure 1 As shown, the present invention includes a housing 3, a heat sink 1 connected to the bottom of the housing 3 and a condenser lens 4 connected to the top of the housing 3, and the top of the heat sink 1 is located at the focal point of incidence of the condenser lens 4 A solar photovoltaic chip 5 is installed at the position, an insulating heat conducting plate 11 is arranged between the solar photovoltaic chip 5 and the heat sink 1, and a conductive plate 6 for outputting electricity is installed above the heat sink 1 on both sides of the solar photovoltaic chip 5, An insulating plate 10 is arranged between the conductive plate 6 and the heat sink 1, the conductive plate 6 is electrically connected to the solar photovoltaic chip 5 through a wire 12, and a secondary heat sink for improving light concentration efficiency is arranged above the solar photovoltaic chip 5. optical system.

[0025] Such as figure 1 As shown, in this embodiment, the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com