Seamless splice structure for aluminum frame corner

A technology of seamless splicing and corner connectors, which is applied to TVs, color TV parts, electrical components, etc., can solve the problems of product competitiveness decline, thickening and bloating, and achieve the effect of saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

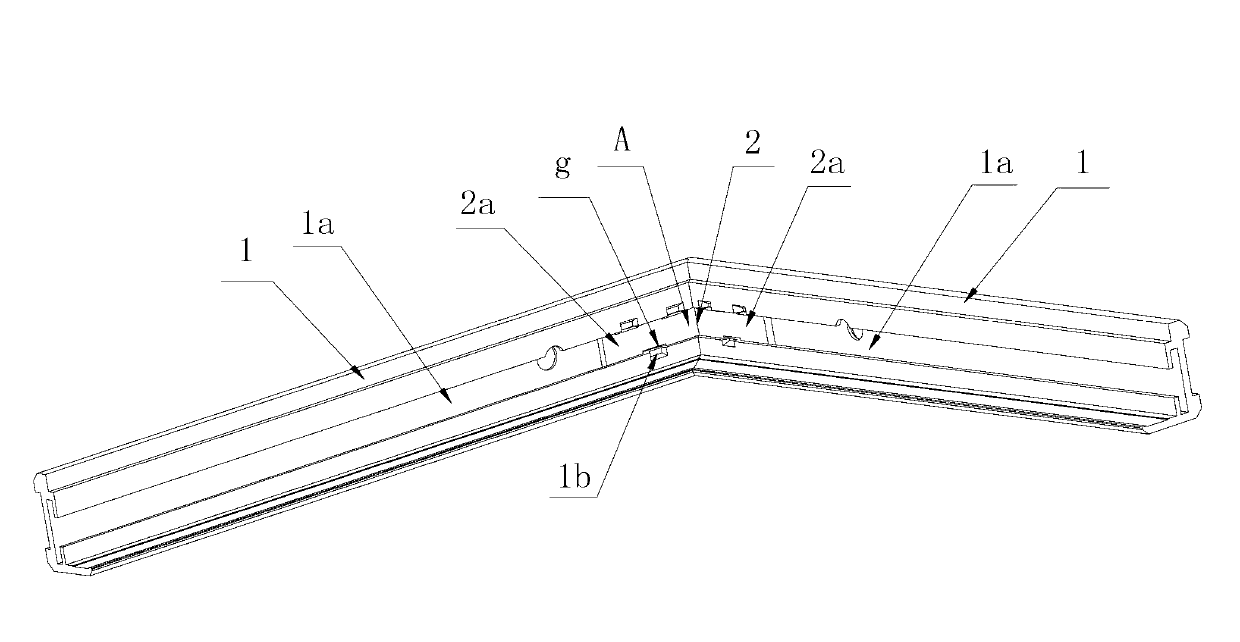

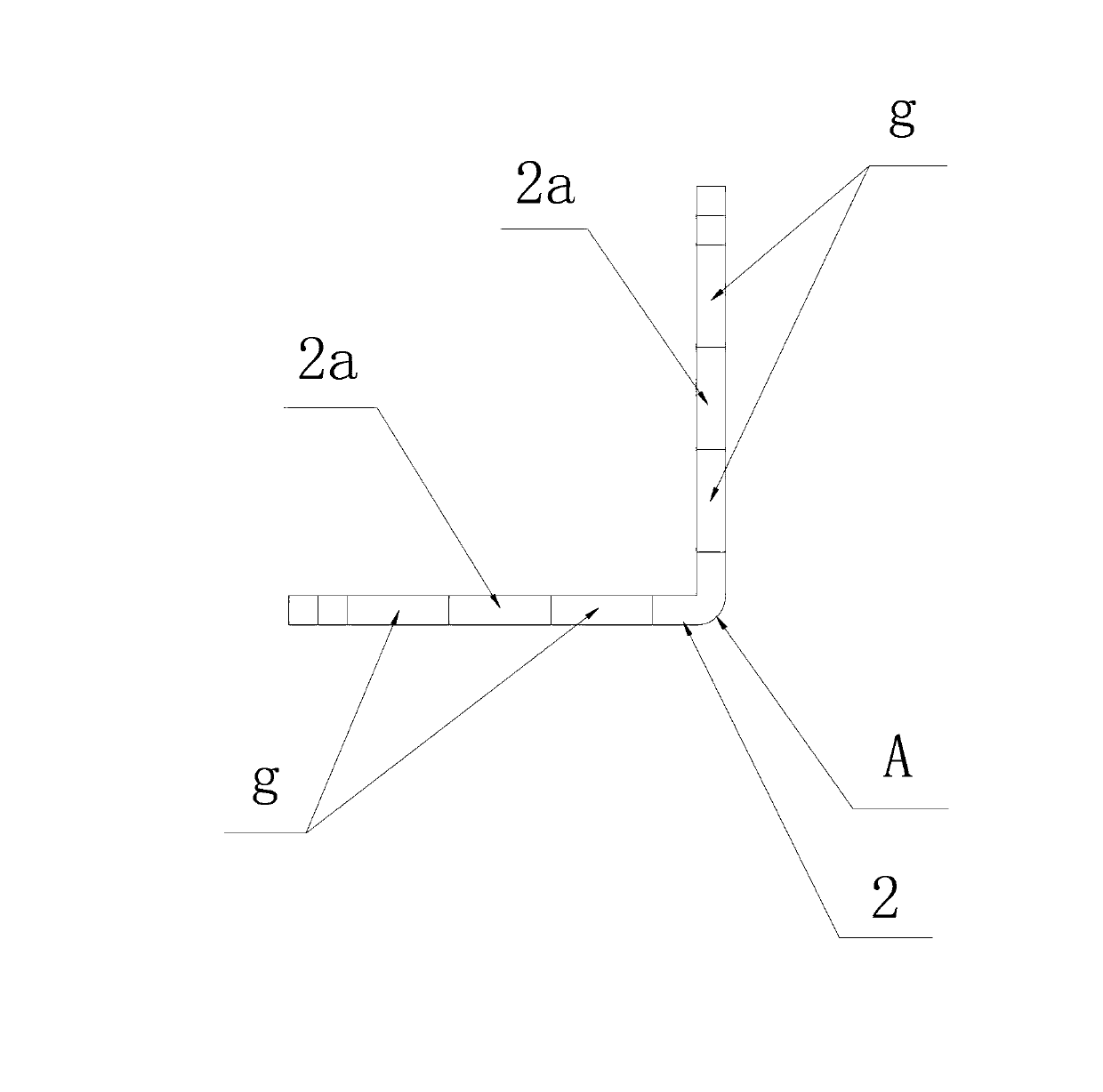

[0021] Example: Combine Figure 1 to Figure 4 As shown, the aluminum frame corner seamless splicing structure provided by the present invention consists of two adjacent extruded aluminum frame strips 1 forming the corner of the aluminum frame by seamless splicing and a corner connector connecting the two extruded aluminum frame strips 1 A common composition. The corner connector A in this embodiment is an "L"-shaped corner member 2, and the two connecting sides 2a of the "L"-shaped corner member 2 are fixed to two aluminum extruded frame strips 1 respectively.

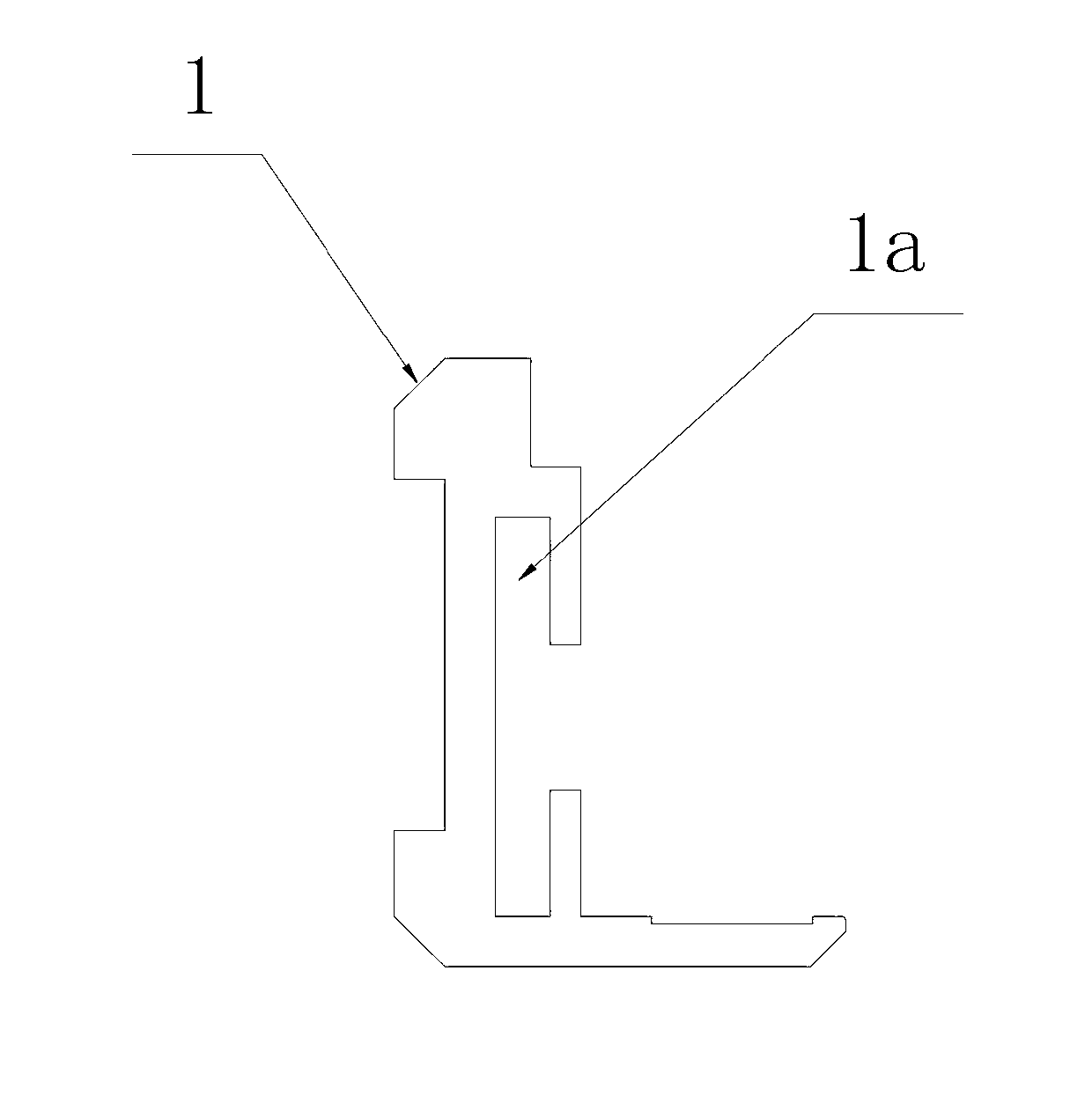

[0022] In this embodiment, each aluminum extruded frame strip 1 is reserved with a slot 1a for inserting the connecting edge 2a of the "L"-shaped corner member 2, see for details figure 2 shown. The knuckle angle of the "L"-shaped knuckle member 2 described in this embodiment (that is, the angle between the two connecting sides 2a) is 90 degrees, and a notch g is provided on both sides of each connecting side 2a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com