Pulverized expanded graphite agglomerate, its preparation method, and its application

A technology of expanded graphite, agglomerates, applied in the direction of graphite, chemical instruments and methods, materials for heat exchange, etc., can solve problems such as workability problems that are not described

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

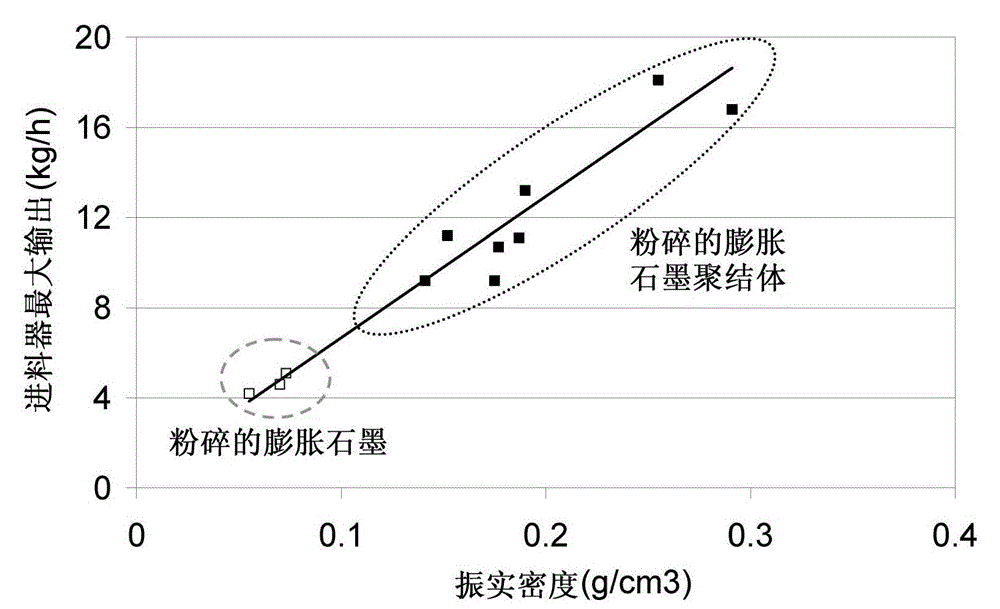

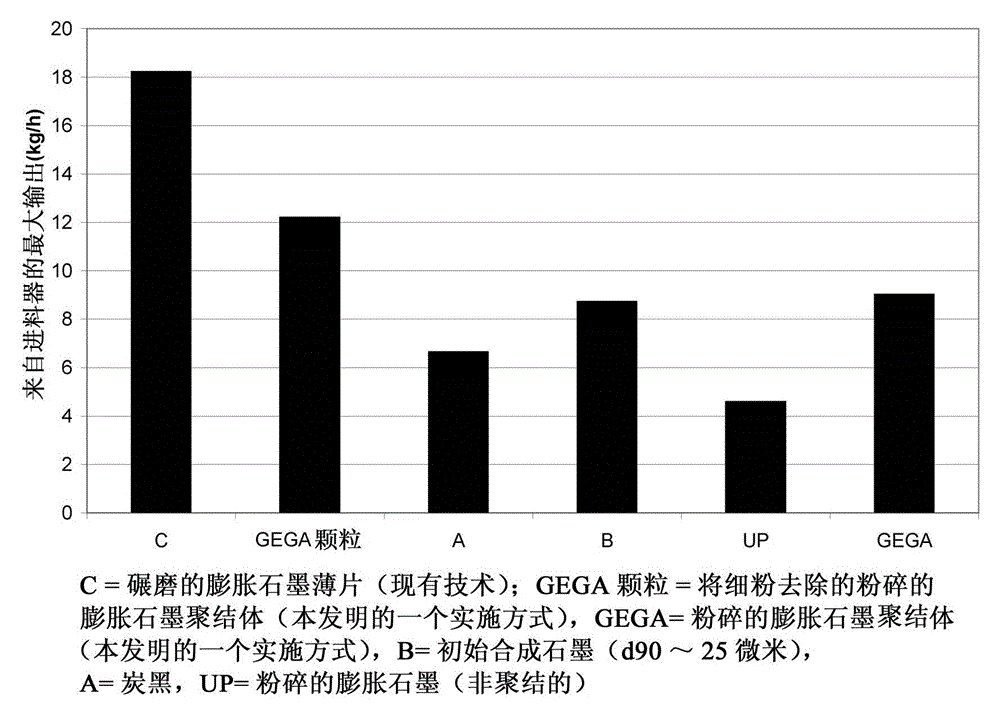

Problems solved by technology

Method used

Image

Examples

Embodiment 1

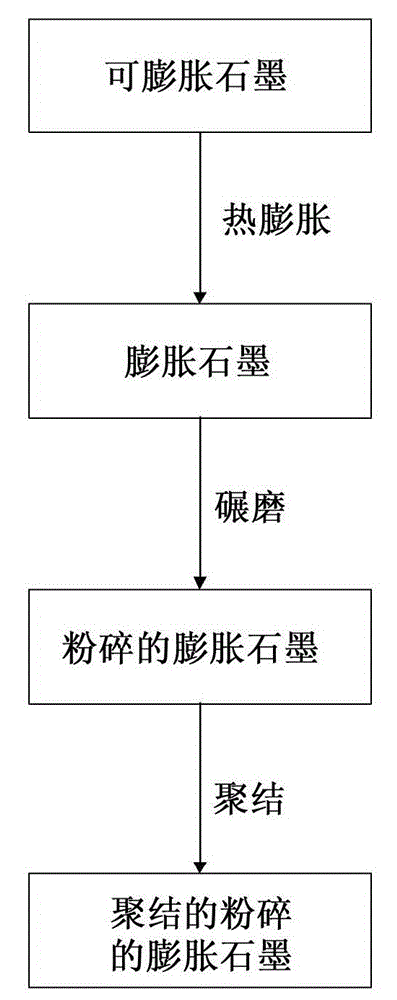

[0136] Example 1 - Coalescence method for expanded graphite

[0137]To prepare comminuted expanded graphite agglomerates, initially comminuted expanded graphite is fed onto a pair of counter-rotating rollers with the aid of a screw. The expanded graphite was pre-coalesced by passing it through rollers. In this example, a drum with a smooth surface was used (although the drum could also have a structured surface to increase productivity). In the second step (fine agglomeration step), the pre-agglomerated expanded graphite is pushed through a final sieve or set of sieves with the help of rotating jaws, which help define the agglomerate size of the comminuted expanded graphite (see Figure 15 ). Adjusting the desired tap density by proper selection of the screw speed, the gap between the rollers, and the mesh size produces the desired soft agglomerates of comminuted expanded graphite (manufactured by Alexanderwerk AG, Remscheid, Germany) Roller compactor PP150).

[0138] The ...

Embodiment 2

[0141] Example 2 - Alternative coalescence method for expanded graphite

[0142] In an alternative setup, agglomerates of comminuted expanded graphite are produced using machines with different geometric arrangements. In this setup, as in Figure 16 As shown in , the material is fed vertically onto counter-rotating drums (Powtec RC210 manufactured by Powtec Maschinen und Engineering, Remscheid, Germany) with the help of a vertical screw. The tap density is again adjusted via screw speed, drum gap and final mesh size.

Embodiment 3

[0143] Example 3 - Alternative coalescence method for expanded graphite

[0144] Pin mixer granulation method

[0145] In an alternative method, the agglomerates can be produced using a pin mixer granulator system generally known in the art. For example, such pin mixer granulator systems are widely used to agglomerate carbon black powders. Pin mixers consist of a cylindrical stable housing and a rotating shaft equipped with pins. Initially comminuted expanded graphite enters the system at one end of the cylinder and, as it moves from the inlet, can be whipped by a rotating pin, through the housing and to the bottom outlet. A fine particle spray of liquid or vapor can be added at the inlet section and distributed throughout the powder, which results in fine mixing and micro-agglomeration of the particles. In this embodiment, the liquid or vapor may be water, although generally any inert liquid will work in this setup. Also, additives can be added at this stage.

[0146] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com