Autonomously calibrated magnetic field sensor

A magnetic field sensor, sensor technology, applied in the direction of magnetic field offset compensation, instruments, measuring magnetic variables, etc., can solve the problem of increasing the total cost of the implementation, reducing the reliability or accuracy of the sensor, and interconnecting the sensor sensor with external circuits and components complication etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

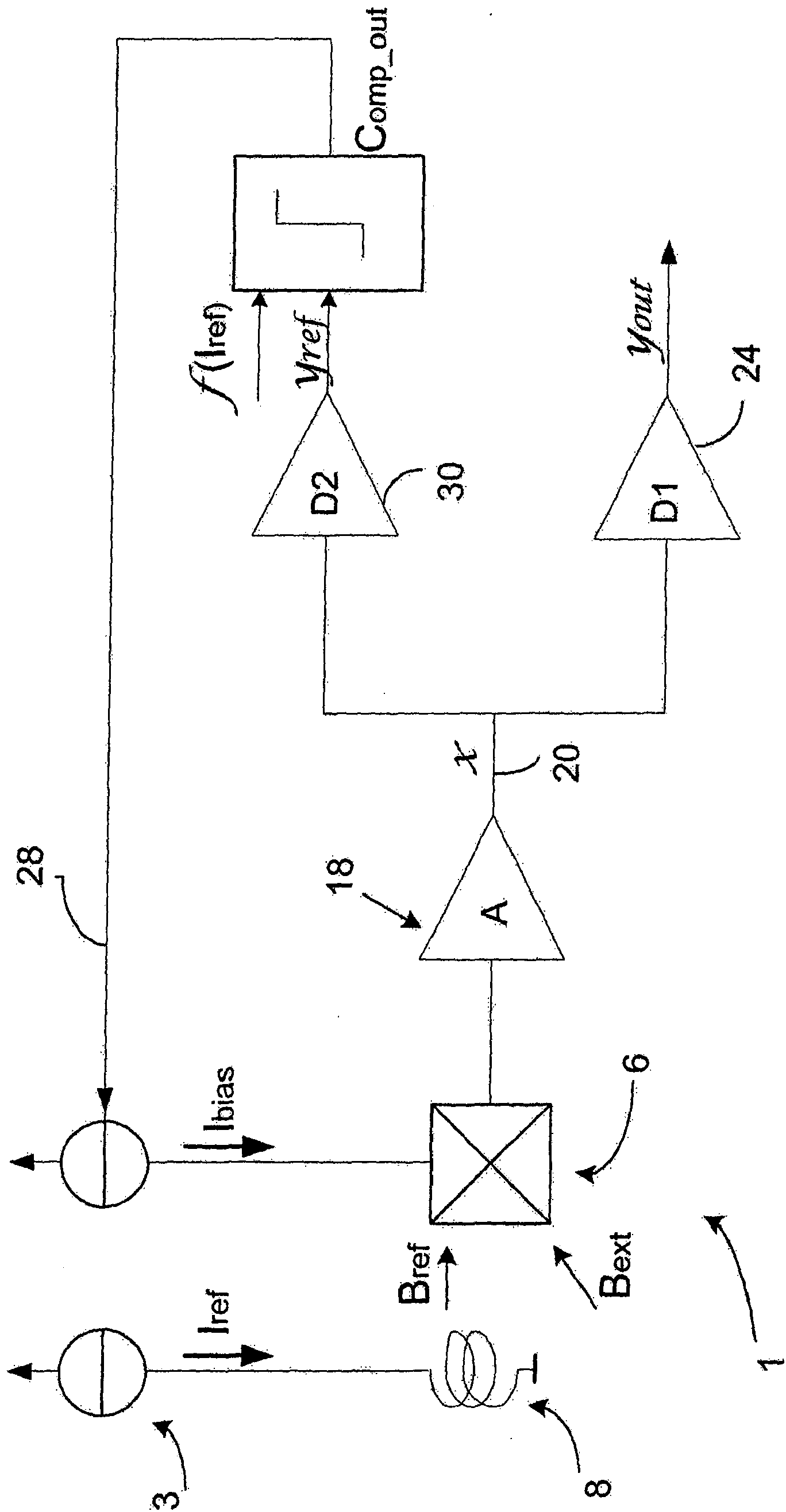

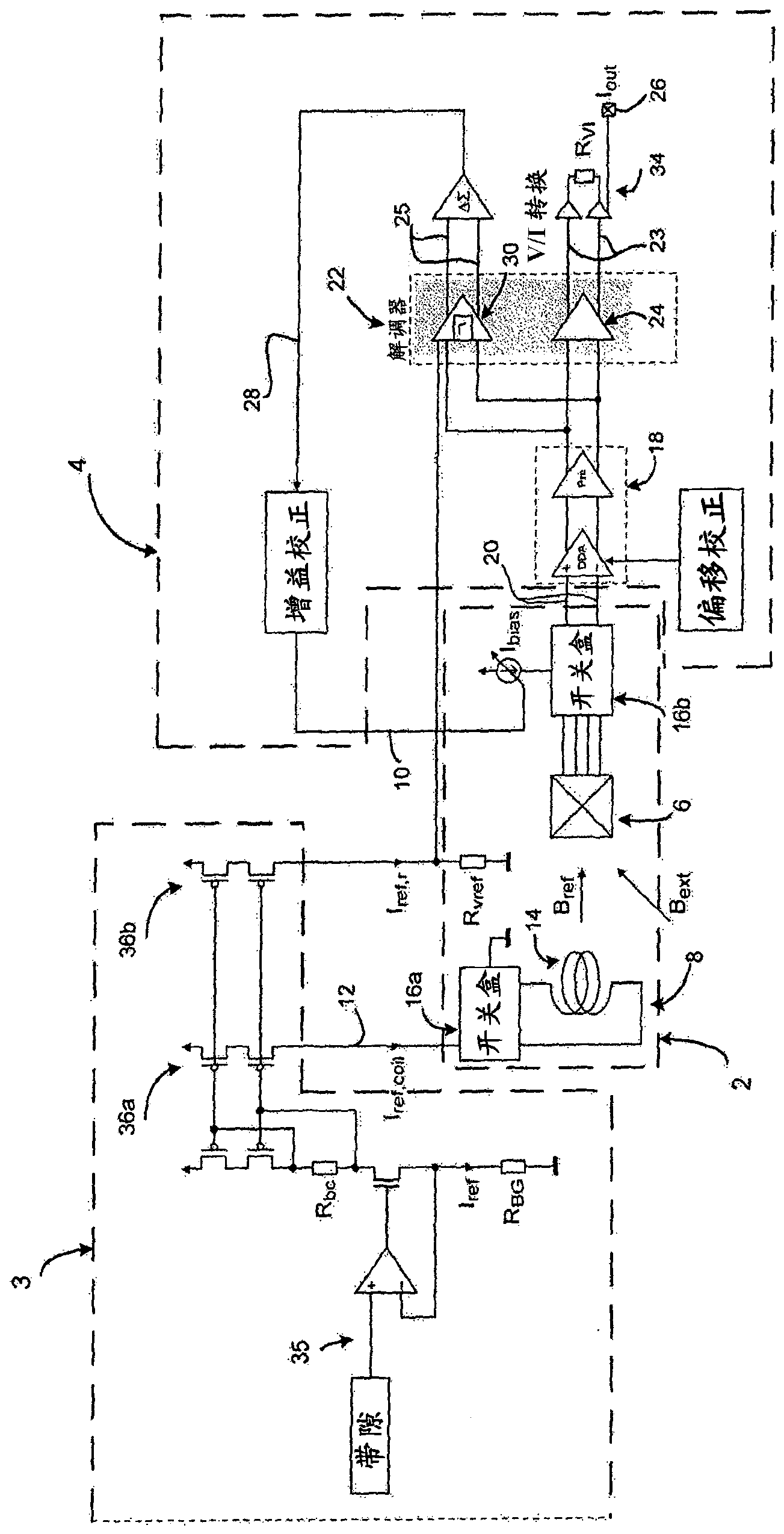

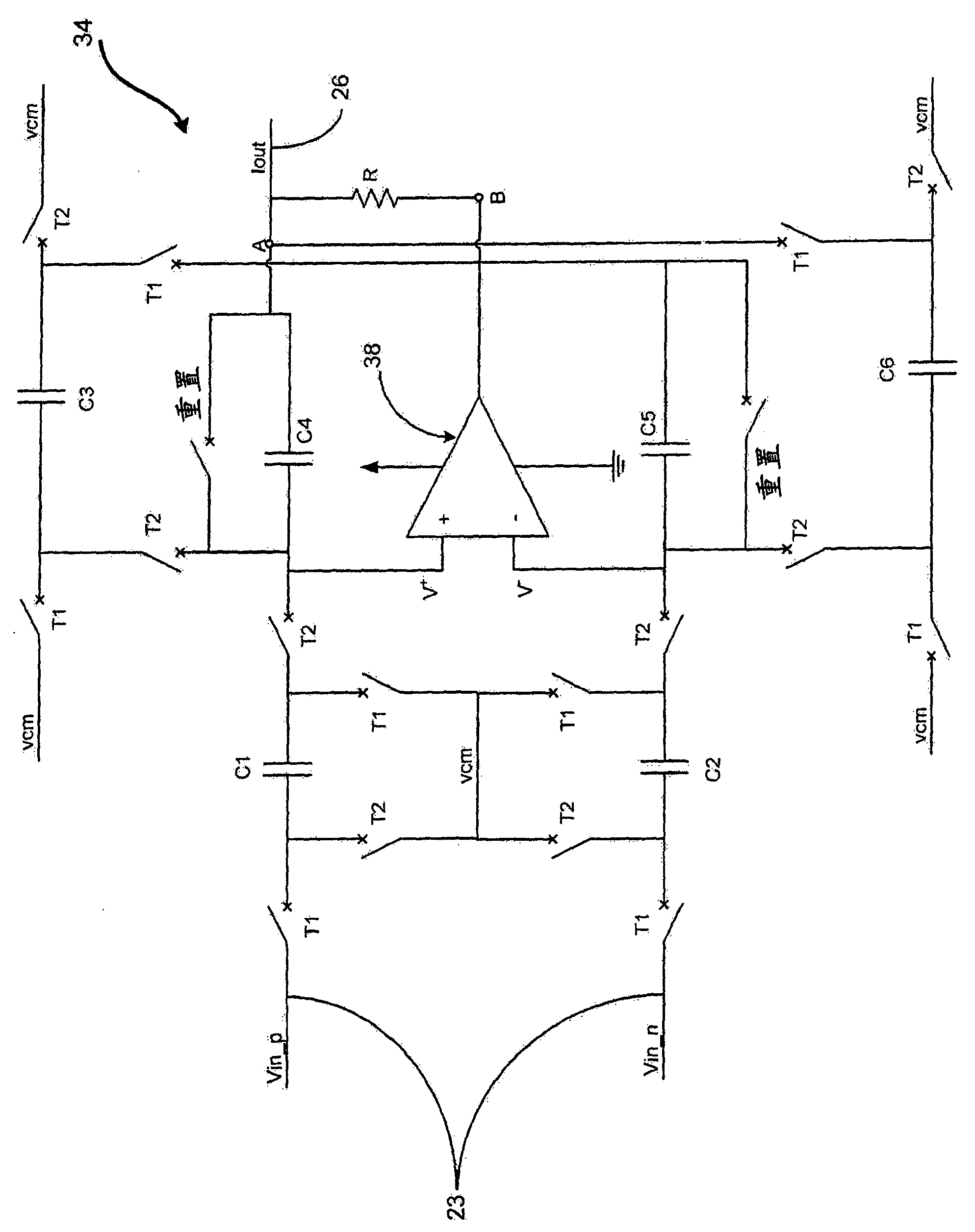

[0022] first reference figure 2 , illustrating the circuit principle of a magnetic field sensor 1 according to an embodiment of the invention is shown generally comprising a magnetic field sensing circuit 2 , an internal reference current generator 3 and a signal processing circuit 4 . The magnetic field sensing circuit 2 includes a magnetic field sensing unit 6 , a reference magnetic field generator 8 and a gain correction input terminal 10 . Based on the detection of the magnetic field generated by the current to be measured, the magnetic field sensor according to the invention can advantageously be used as a current sensor. The magnetic field sensor according to the invention can also be implemented in other magnetic field sensing applications.

[0023] The magnetic field sensing unit 6 may include one or more magnetic field sensing elements, for example, a Hall effect sensor as known in the art or a Hall effect sensor array formed in an integrated circuit, and the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com