battery current sensor

A battery current and sensor technology, applied in voltage/current isolation, instruments, circuits, etc., can solve the problems of easy damage, bulky and expensive current sensors, etc., to achieve compact manufacturing, complex battery connections, and less susceptible to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

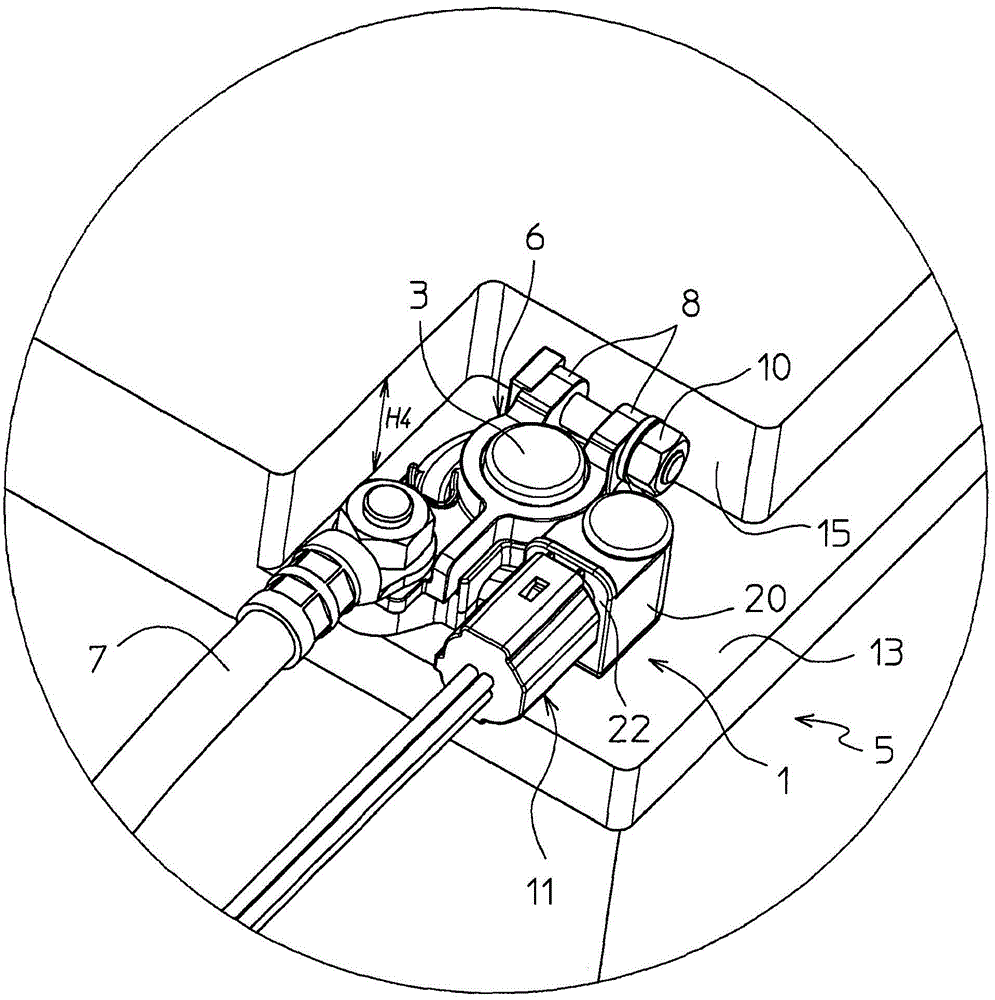

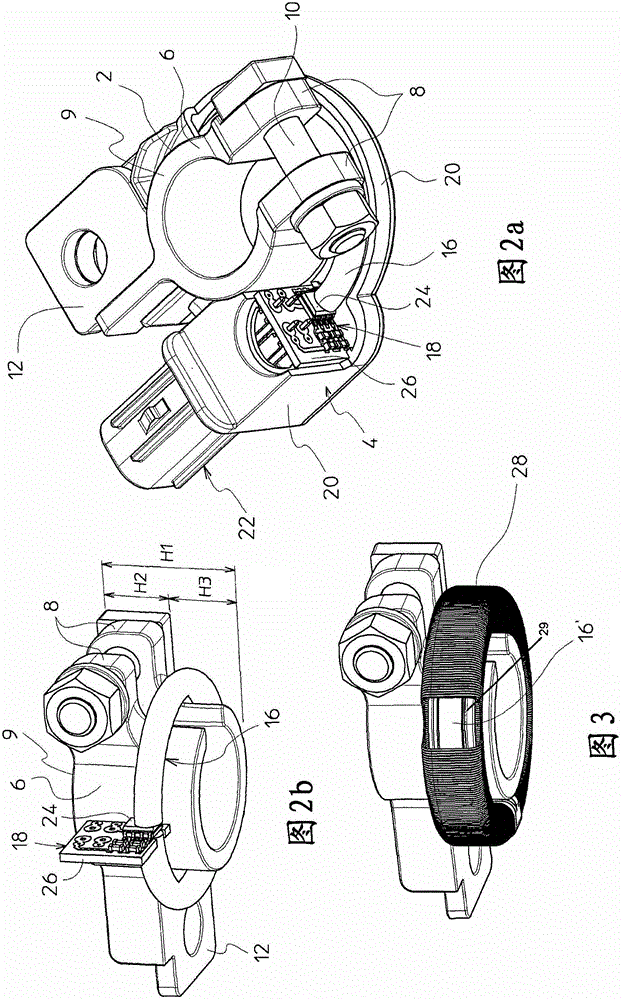

[0022] With reference to the drawings, a battery current sensor 1 according to an embodiment of the present invention includes a battery pole connection clamp part 2 and a current sensing part 4. The battery pole connecting clamp part can be installed around the battery pole 3 of the battery 5, where the battery 5 is generally a lead-acid type widely used in automobiles, backups or other applications. As is well known in itself, the battery pole can have standardized dimensions with a slightly tapered clamping surface. However, the present invention can also be used for other types of batteries or for cylindrical or slightly tapered battery terminals with non-standardized dimensions.

[0023] The battery pole connection clamp portion 2 includes a split tubular clamping body 6 having a flange 8 extending outwardly and radially from and generally from the free end of the clamping body, the flange having a flange received therethrough The clamping bolt 10 can be pressed together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com