Composite build-up material for embedding of circuitry

A technology of circuits and mixtures, applied in the directions of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve problems such as uneven laser ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

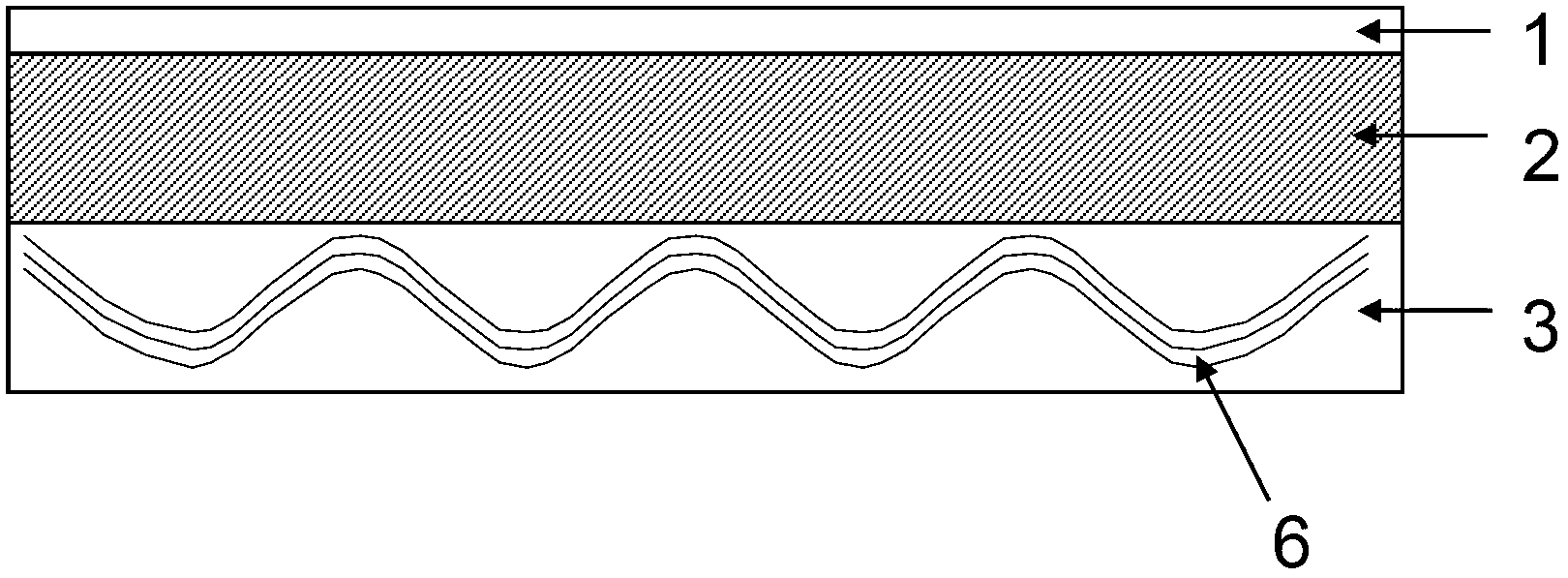

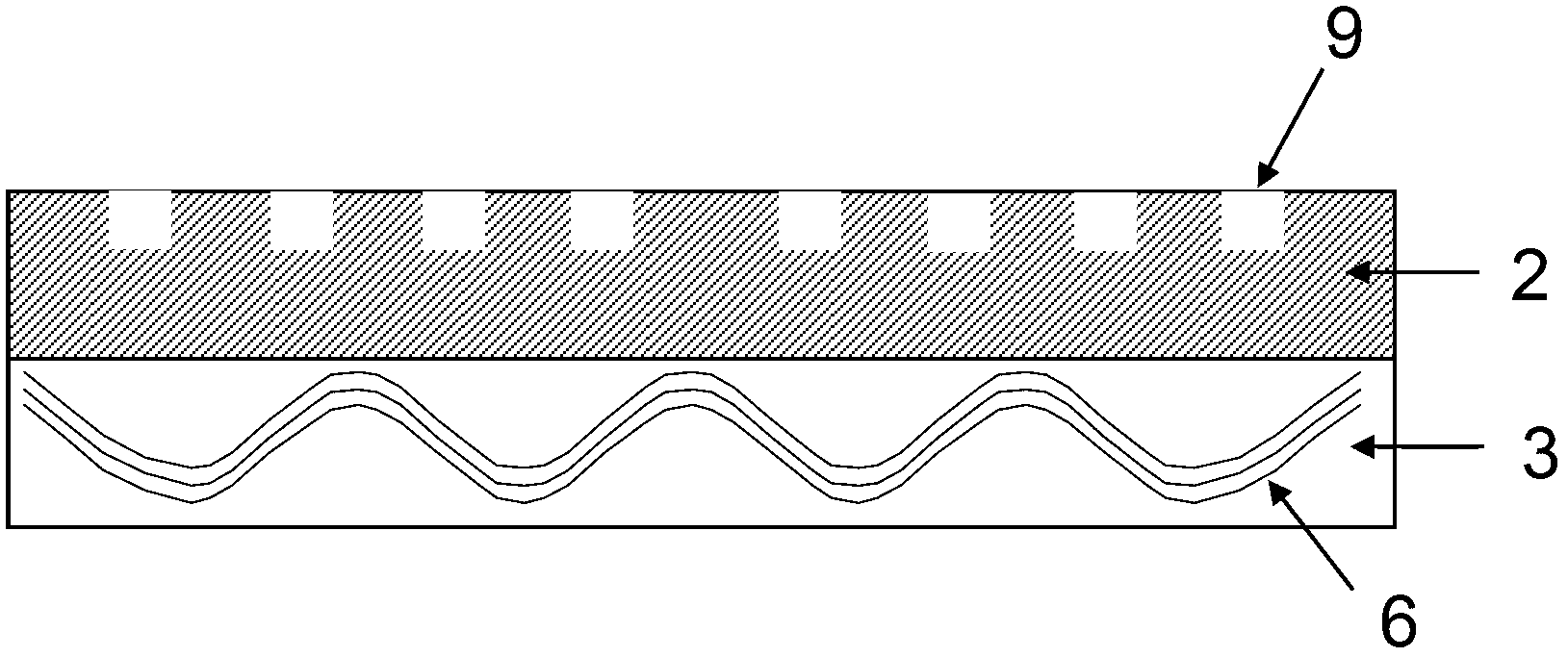

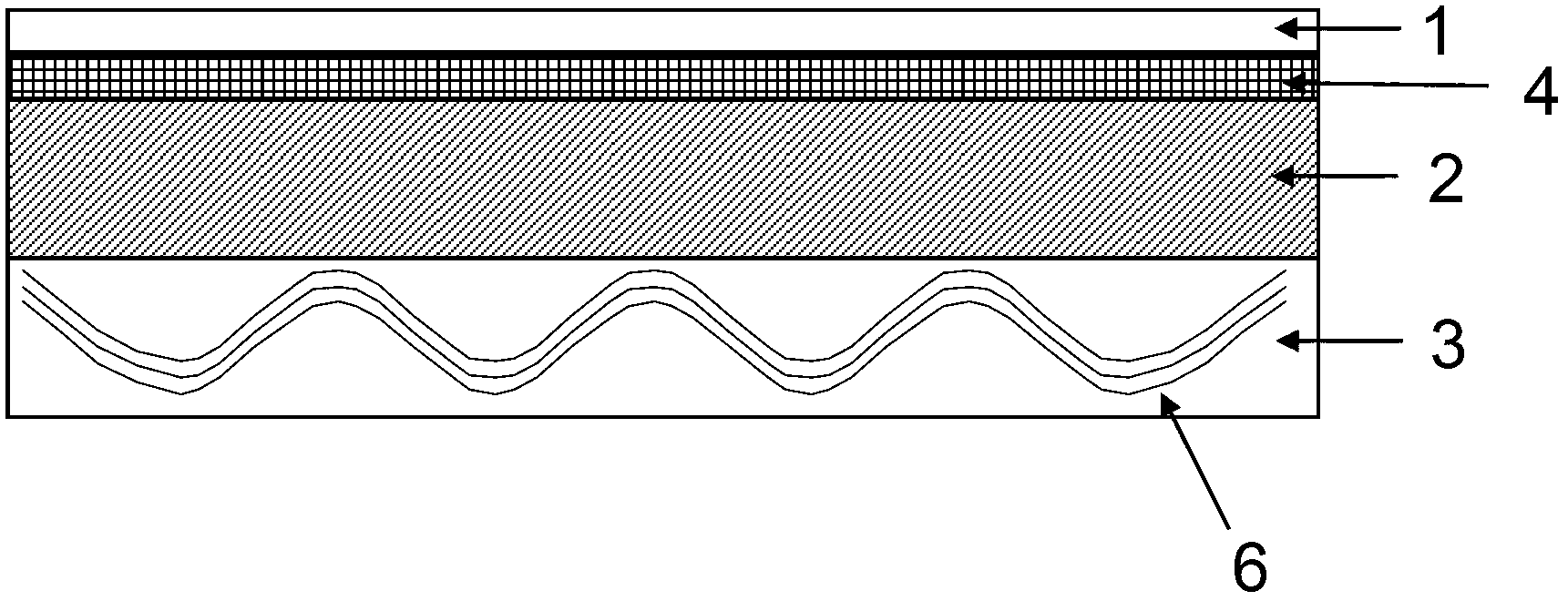

[0143] Preparation of resin powders for layers (2) and (3)

[0144] The resin components listed in Table 1 were weighed in the amounts indicated and thoroughly mixed together in polyethylene bags.

[0145] Table 1: Components for resin powder preparation of resin layers (2) and (3)

[0146] components

Quantity (g)

Multifunctional solid epoxy resin

480

Bakelit PF 0790 K03

180

Submicron Size Silicon Oxide

338

Total:

998

[0147] Use dicyclopentadienyl-bridged polyfunctional solid epoxy resin, Bakelit PF 0790 K03, which is a phenolic-based phenolic resin (CAS-no.9003-35-4), and has a 0.3 micron average Submicron sized silica fillers in particle size and spherical particle shape are used as raw materials. The mixed dielectric components were then extruded on a 19 mm-hole, 5-zone, 24 l / d twin-screw extruder produced by OMC, Italy and equipped with a screw with maximum number of mixing elements. The barrel temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com